This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

Introduction

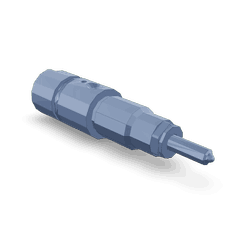

The Cummins 3944828 injector is a component designed for use in commercial trucks, specifically within Cummins diesel engines. Its purpose is to deliver fuel into the combustion chamber in a precise and controlled manner, which is vital for the efficient operation of the engine. The significance of this injector lies in its ability to enhance the performance and efficiency of the truck’s engine, contributing to overall vehicle operation 1.

Basic Concepts of Fuel Injectors

Fuel injectors are devices that spray fuel into an engine’s combustion chamber. They operate by atomizing fuel into a fine mist, which mixes with air before combustion. This process is crucial for the efficient burning of fuel, which in turn powers the engine. The role of fuel injectors in the combustion process cannot be overstated, as they directly influence engine performance, fuel efficiency, and emissions 2.

Role of the 3944828 Injector in Truck Operation

The Cummins 3944828 injector plays a specific role in the operation of a truck by ensuring precise fuel delivery to the engine’s combustion chambers. This injector is designed to work under high pressure, which allows for better atomization of the fuel. Improved atomization leads to more efficient combustion, which enhances engine performance and fuel economy. Additionally, the injector contributes to maintaining consistent engine operation by delivering the correct amount of fuel at the right time 3.

Key Features of the 3944828 Injector

The Cummins 3944828 injector is characterized by several key features that enhance its performance. Its design incorporates advanced technology to ensure precise fuel delivery. The materials used in its construction are chosen for their durability and resistance to the high pressures and temperatures within a diesel engine. Technological advancements in the injector’s design contribute to its reliability and efficiency in demanding commercial truck applications 4.

Benefits of Using the 3944828 Injector

Utilizing the Cummins 3944828 injector offers several advantages. It contributes to improved fuel efficiency by ensuring that fuel is used more effectively during combustion. Enhanced engine performance is another benefit, as the injector’s precise fuel delivery supports optimal engine operation. Additionally, the injector helps in reducing emissions, aligning with environmental regulations and promoting sustainable operation of commercial trucks 5.

Installation and Integration

Proper installation and integration of the Cummins 3944828 injector within a truck’s engine system are crucial for its effective operation. This process involves ensuring that the injector is correctly positioned and secured within the engine. Any necessary adjustments should be made according to the manufacturer’s guidelines to ensure compatibility with the engine’s fuel system and to achieve optimal performance 6.

Maintenance and Troubleshooting

Maintaining the Cummins 3944828 injector is important for ensuring its longevity and performance. Regular checks and cleaning can prevent buildup and ensure smooth operation. Troubleshooting common issues, such as inconsistent fuel delivery or engine performance problems, may involve inspecting the injector for signs of wear or damage and addressing any issues promptly to maintain engine efficiency 7.

Performance Enhancements

The Cummins 3944828 injector contributes to overall engine performance by enhancing power output, torque, and fuel economy. Its precise fuel delivery ensures that the engine operates at its peak efficiency, which is crucial for the demanding conditions faced by commercial trucks. The injector’s role in these performance enhancements underscores its importance in the engine system 8.

Environmental Impact

The use of the Cummins 3944828 injector has positive environmental implications. By promoting more efficient combustion, it helps in reducing emissions, which is beneficial for the environment. Improved fuel efficiency also means less fuel is consumed, further contributing to lower emissions and a reduced carbon footprint for commercial truck operations 9.

Cummins Corporation Overview

Cummins Inc. is a global power leader that designs, manufactures, and distributes a wide range of power solutions, including diesel engines and related technologies. With a history of innovation and a commitment to sustainability, Cummins has established a reputation for quality and reliability in the automotive and heavy-duty truck industries. The company’s mission is to make people’s lives better by powering a more prosperous world 10.

Compatibility of Cummins Injector Part 3944828

The Cummins injector part number 3944828 is designed to fit seamlessly within the ISB CM550 and QSB5.9 44 CM550 engines. This injector is engineered to ensure optimal fuel delivery and combustion efficiency, crucial for maintaining the performance and longevity of these engines 11.

Understanding the Role of Part 3944828 Injector in Engine Systems

The part 3944828 Injector is an integral component within the engine system, designed to deliver precise amounts of fuel into the combustion chamber. Its operation is synchronized with the engine’s control unit to ensure optimal fuel delivery based on the engine’s demand and operating conditions 12.

Integration with Injector Plumbing

The injector is meticulously connected to the injector plumbing, a network of fuel lines and rails that transport fuel from the tank to the injectors. This plumbing system is engineered to maintain consistent fuel pressure and temperature, ensuring the injector operates within its specified parameters. The 3944828 Injector interfaces with this system through secure fittings that prevent leaks and ensure a stable fuel supply 13.

Interaction with Engine Control Unit (ECU)

The 3944828 Injector communicates with the Engine Control Unit (ECU) via electrical connections. The ECU monitors various engine parameters such as engine speed, load, and temperature. Based on this data, the ECU sends signals to the injector to open and close at precise moments, controlling the fuel injection timing and duration. This interaction is vital for maintaining efficient combustion and minimizing emissions 14.

Role in Fuel Atomization

Upon receiving the signal from the ECU, the 3944828 Injector atomizes the fuel into fine particles as it is sprayed into the combustion chamber. This atomization is essential for achieving a homogeneous air-fuel mixture, which is critical for complete combustion. The design of the injector nozzle plays a significant role in this process, ensuring that the fuel is dispersed evenly across the combustion chamber 15.

Contribution to Engine Performance

The performance of the 3944828 Injector directly influences the engine’s overall efficiency, power output, and emissions. By delivering fuel in a controlled and precise manner, the injector helps to optimize the air-fuel ratio, leading to improved fuel economy and reduced exhaust emissions. Additionally, the injector’s ability to respond quickly to changes in engine demand contributes to smoother operation and enhanced drivability 16.

Maintenance and Monitoring

Regular maintenance of the 3944828 Injector and its associated components is essential to ensure continued optimal performance. This includes checking for leaks in the injector plumbing, verifying the injector’s electrical connections, and monitoring the injector’s performance through diagnostic tools. Proper maintenance helps to prevent issues such as misfires, reduced power, and increased emissions 17.

Conclusion

In summary, the Cummins 3944828 Injector plays a significant role in the engine system by ensuring precise fuel delivery, interacting with the ECU, contributing to fuel atomization, and influencing overall engine performance. Its integration with the injector plumbing and the ECU highlights the importance of this component in modern engine designs.

-

Bennett, S. (2012). Modern Diesel Technology: Light Duty Diesels. Cengage Learning.

↩ -

Khajepour, A. (2023). Synthesis Lectures on Advances in Automotive Technology. Springer.

↩ -

Norman, A. (2016). Diesel Technology Fundamentals Service Repair Eighth Edition. The Goodheart-Willcox Company Inc.

↩ -

Cummins Inc. (n.d.). Operation and Maintenance Manual for KTA19 G CMEICS K123. Bulletin Number 4383850.

↩ -

Bennett, S. (2012). Modern Diesel Technology: Light Duty Diesels. Cengage Learning.

↩ -

Cummins Inc. (n.d.). Operation and Maintenance Manual for KTA19 G CMEICS K123. Bulletin Number 4383850.

↩ -

Norman, A. (2016). Diesel Technology Fundamentals Service Repair Eighth Edition. The Goodheart-Willcox Company Inc.

↩ -

Cummins Inc. (n.d.). Operation and Maintenance Manual for KTA19 G CMEICS K123. Bulletin Number 4383850.

↩ -

Khajepour, A. (2023). Synthesis Lectures on Advances in Automotive Technology. Springer.

↩ -

Cummins Inc. (n.d.). Company Overview. Retrieved from Cummins Official Website.

↩ -

Cummins Inc. (n.d.). Operation and Maintenance Manual for KTA19 G CMEICS K123. Bulletin Number 4383850.

↩ -

Bennett, S. (2012). Modern Diesel Technology: Light Duty Diesels. Cengage Learning.

↩ -

Cummins Inc. (n.d.). Operation and Maintenance Manual for KTA19 G CMEICS K123. Bulletin Number 4383850.

↩ -

Khajepour, A. (2023). Synthesis Lectures on Advances in Automotive Technology. Springer.

↩ -

Norman, A. (2016). Diesel Technology Fundamentals Service Repair Eighth Edition. The Goodheart-Willcox Company Inc.

↩ -

Cummins Inc. (n.d.). Operation and Maintenance Manual for KTA19 G CMEICS K123. Bulletin Number 4383850.

↩ -

Norman, A. (2016). Diesel Technology Fundamentals Service Repair Eighth Edition. The Goodheart-Willcox Company Inc.

↩

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.