3955220

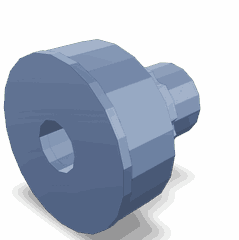

Vibration Isolator

Cummins®

IN STOCK

More than 10 are currently available

Ships within 1 business day

This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

The Cummins 3955220 Vibration Isolator is a component designed to mitigate the transmission of vibrations from the engine to the truck’s frame and other components. Its role is significant in the operation of commercial trucks, contributing to the overall efficiency and longevity of the vehicle 1.

Basic Concepts of Vibration Isolators

Vibration isolators are devices that reduce the transmission of vibrations between two surfaces. They function by absorbing or dampening the vibrational energy, thereby minimizing its impact on connected components. In mechanical systems, particularly heavy-duty trucks, vibration isolators play a role in maintaining the integrity and performance of various parts by reducing stress and wear 2. The principles of vibration isolation involve the use of materials and designs that can absorb, reflect, or redirect vibrational energy, ensuring that the system operates smoothly and efficiently.

Purpose of the 3955220 Vibration Isolator

The 3955220 Vibration Isolator serves to reduce vibrations transmitted from the engine to the truck’s frame and other components. By doing so, it helps in maintaining the structural integrity of the truck, ensuring that the engine operates within optimal parameters, and enhancing the overall driving experience by minimizing unwanted vibrations 3.

Key Features

The 3955220 Vibration Isolator is characterized by its robust design and the use of high-quality materials. It is engineered to withstand the rigors of heavy-duty truck operations, providing reliable vibration isolation. The isolator’s design incorporates features that enhance its performance, such as precise engineering to ensure compatibility with specific engine models and truck frames.

Benefits of Using the 3955220 Vibration Isolator

Incorporating the 3955220 Vibration Isolator in truck designs offers several advantages. It contributes to improved ride comfort by reducing the transmission of engine vibrations to the cabin. Additionally, it helps in reducing wear and tear on truck components, extending their lifespan. The isolator also plays a role in enhancing engine performance by ensuring that the engine operates in a stable environment, free from excessive vibrations.

Installation Considerations

When installing the 3955220 Vibration Isolator, it is important to follow guidelines and best practices to ensure optimal performance. Proper alignment and adherence to torque specifications are crucial for the isolator to function effectively. Prerequisites for installation may include ensuring that the mounting surfaces are clean and free from debris, and that all necessary hardware is in place.

Troubleshooting Common Issues

Common problems associated with vibration isolators include excessive vibration, wear and tear, and performance issues. Diagnosing these problems involves a systematic approach to identifying the source of the vibration, inspecting the isolator for signs of wear, and addressing any issues that may affect its performance. Regular inspections and maintenance can help in preventing these issues.

Maintenance Tips

Regular maintenance of the 3955220 Vibration Isolator is important to ensure its continued performance. This includes inspecting the isolator for signs of wear, such as cracks or deformation, and replacing it when necessary. Maintenance intervals may vary depending on the operating conditions and the specific requirements of the truck.

Cummins Corporation Overview

Cummins Inc. is a global power leader that designs, manufactures, and distributes engines, filtration, and power generation products. The company has a long history of innovation in the automotive industry, particularly in the production of diesel engines and related components. Cummins is known for its commitment to quality and performance, providing solutions that meet the demanding requirements of commercial and industrial applications.

Compatibility with Cummins Engines

The Cummins part 3955220, a Vibration Isolator, is designed to be compatible with a range of Cummins engines, ensuring effective noise and vibration reduction. This part is integral in maintaining the operational integrity and longevity of the engines by mitigating the adverse effects of vibrations.

ISB Series Engines

The ISB series engines, including the ISB CM2150, ISB CM850, ISB/ISD4.5 CM2150 B119, ISB/ISD6.7 CM2150 SN, ISB4.5 CM2350 B104, ISB5.9 CM2880 B110, ISB5.9 CM2880 B140, ISB5.9 CM2880 B149, ISB5.9G CM2180, ISB6.7 CM2250, ISB6.7 CM2350 B101, ISB6.7 G CM2180 B118, ISBE CM2150, and ISBE4 CM850, all benefit from the installation of the 3955220 Vibration Isolator. This compatibility ensures that these engines operate smoothly, reducing wear and tear on engine components and enhancing overall performance.

ISC Series Engines

Similarly, the ISC CM2150 and ISC CM850 engines are also designed to integrate seamlessly with the 3955220 Vibration Isolator. This compatibility is crucial for maintaining the operational efficiency of these engines, ensuring that they run quietly and with minimal vibration.

Other Cummins Engines

The 3955220 Vibration Isolator is also compatible with a variety of other Cummins engines, including the 15N CM2380 M104B, 6C8.3, B4.5 CM2350 B129B, B5.6 CM2670 B152B, B6.7 CM2350 B135B, B6.7 CM2670 B153B, B6.7 CM2670 B164C, F3.8 CM2350 F120B, and F3.8 CM2350 F128C. This broad compatibility underscores the versatility and effectiveness of the 3955220 Vibration Isolator in managing engine vibrations across different engine models.

Role of Part 3955220 Vibration Isolator in Engine Systems

The Part 3955220 Vibration Isolator is integral to maintaining the stability and efficiency of various engine systems. It is strategically positioned to mitigate vibrations that can arise from the operation of high-stress components.

Integration with Engine Components

-

Electronic Control Module (ECM) and Fuel Control Module: The Vibration Isolator ensures that the ECM and Fuel Control Module operate without interference from engine vibrations. This stability is essential for precise electronic control and fuel management.

-

Harness and Wiring: By reducing vibrations, the isolator helps protect the delicate wiring and harnesses connected to the ECM and other electronic components, preventing potential damage and ensuring reliable signal transmission.

-

Fuel Transfer Pump: The isolator supports the Fuel Transfer Pump by minimizing vibrations, which can otherwise lead to inefficiencies in fuel delivery and increased wear on the pump components.

-

Ignition System: A stable ignition system is vital for consistent engine performance. The Vibration Isolator helps maintain this stability by reducing the impact of engine vibrations on ignition components.

-

Engine Cooling Fan Shroud: The isolator assists in keeping the engine cooling fan shroud secure and operational, ensuring effective airflow and temperature management within the engine compartment.

-

Gasket Kits: Whether it’s the complete engine gasket kit, full engine gasket set, lower engine gasket kit, or upper engine gasket kit, the Vibration Isolator plays a role in preserving the integrity of these gaskets by minimizing vibrational stress.

-

Service Kit: As part of a comprehensive service kit, the Vibration Isolator contributes to the overall durability and performance of the engine by addressing vibrational concerns that can affect multiple components.

-

Monitor and Electronic Engine Components: For monitors and other electronic engine components, the isolator ensures that data collection and engine monitoring functions are not compromised by vibrations.

Conclusion

In summary, the Part 3955220 Vibration Isolator is a key component in enhancing the reliability and performance of various engine systems by effectively managing vibrational forces. Its integration with a wide range of Cummins engines underscores its versatility and importance in maintaining engine stability and efficiency.

-

Department of Energy Fundamentals Handbook, Department of Energy, 2015.

↩ -

Design and Development of Heavy Duty Diesel Engines: A Handbook, P. A. Lakshminarayanan, Avinash Kumar Agarwal, Springer, 2019.

↩ -

SAE International’s Dictionary for Automotive Engineers, John F Kershaw, SAE International, 2023.

↩

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.