3966805

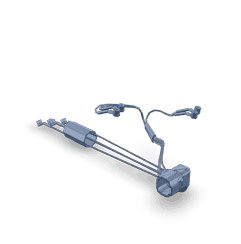

Wiring Harness

Cummins®

IN STOCK

More than 10 are currently available

Ships within 1 business day

This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

Introduction

The Cummins 3966805 Wiring Harness is a specialized component designed for use in commercial trucks. It serves as a vital part of the vehicle’s electrical system, facilitating the connection between various electrical components and the truck’s power source. This wiring harness is integral to ensuring the reliable operation of electrical systems within the truck, contributing to overall vehicle performance and safety.

Basic Concepts of Wiring Harnesses

A wiring harness is an assembly of wires, connectors, and sometimes switches and relays that transmit electrical power and signals throughout a vehicle. It is designed to organize and protect the wires, reducing the risk of damage and improving the efficiency of the electrical system. Within a vehicle, the wiring harness plays a role in connecting the battery to other electrical components, such as lights, sensors, and the engine control unit, enabling the coordinated operation of these parts 1.

Purpose of the 3966805 Wiring Harness

The Cummins 3966805 Wiring Harness is specifically engineered to support the electrical needs of commercial trucks. It provides a structured pathway for electrical signals and power, ensuring that all connected components receive the necessary voltage and current. This harness is designed to integrate with the truck’s existing electrical system, enhancing functionality and reliability. Its applications include powering and controlling various truck systems, such as lighting, engine management, and auxiliary equipment.

Key Features

The 3966805 Wiring Harness is characterized by its robust design and high-quality materials. It is constructed using durable wires and connectors that are resistant to wear, corrosion, and environmental factors. The harness is designed to withstand the demanding conditions of commercial truck operations, ensuring long-term performance and reliability. Unique attributes of this harness include its organized layout, which simplifies installation and maintenance, and its compatibility with a range of truck models.

Benefits of Using the 3966805 Wiring Harness

Utilizing the Cummins 3966805 Wiring Harness offers several advantages. It contributes to improved efficiency by ensuring that electrical components receive consistent and adequate power. The harness enhances the reliability of the truck’s electrical system, reducing the likelihood of failures and malfunctions. Additionally, by providing a secure and organized pathway for electrical connections, it plays a role in enhancing the safety of truck operations.

Installation Considerations

When installing the 3966805 Wiring Harness, it is important to follow guidelines and best practices to ensure proper integration with the truck’s electrical system. Preparatory steps may include disconnecting the battery to prevent electrical shocks and ensuring that the work area is clean and free of obstructions. The use of appropriate tools, such as wire strippers and crimping tools, is recommended to facilitate a secure and efficient installation process.

Maintenance and Troubleshooting

To ensure the longevity and optimal performance of the 3966805 Wiring Harness, regular maintenance is advised. This includes inspecting the harness for signs of wear, corrosion, or damage and addressing any issues promptly. Common problems that may arise include loose connections or damaged wires, which can be resolved by tightening connections or replacing affected sections of the harness. Adhering to a maintenance schedule helps prevent more significant issues and ensures the continued reliability of the truck’s electrical system.

Compatibility and Applications

The Cummins 3966805 Wiring Harness is designed for use in specific types of trucks and engines. It is important to verify compatibility with the intended application to ensure proper fit and function. Specific application notes may provide additional guidance on installation and usage, helping to achieve the best results.

Safety Precautions

When working with the 3966805 Wiring Harness, observing important safety measures is crucial. This includes adhering to electrical safety practices, such as disconnecting the battery before beginning work and using insulated tools to prevent electrical shocks. Handling guidelines should be followed to avoid damage to the harness and ensure personal safety during installation and maintenance procedures.

Cummins Overview

Cummins Inc. is a global power leader that designs, manufactures, and distributes engines, filtration, and power generation products. With a history of innovation and a commitment to quality, Cummins plays a significant role in the commercial truck industry. The company’s products are known for their reliability, efficiency, and performance, contributing to the success of commercial truck operations worldwide.

Wiring Harness 3966805 Compatibility with Cummins Engines

The Cummins Wiring Harness part number 3966805 is designed to be compatible with a range of Cummins engines, ensuring seamless integration and reliable performance. This wiring harness is engineered to meet the specific electrical needs of the engines it is intended for.

ISB CM850

The ISB CM850 engine benefits from the 3966805 wiring harness, which is tailored to handle the electrical demands of this model. This harness ensures that all electrical components are properly connected, facilitating efficient operation and maintenance.

QSB5.9 CM850

Similarly, the QSB5.9 CM850 engine is designed to work with the 3966805 wiring harness. This compatibility ensures that the harness can manage the electrical requirements of the QSB5.9 CM850, providing a robust and dependable connection for all necessary components.

QSB6.7 CM850 (CM2850)

The QSB6.7 CM850 (CM2850) engine also integrates seamlessly with the 3966805 wiring harness. This harness is specifically designed to cater to the higher electrical demands of the QSB6.7 CM850, ensuring that all electrical systems are properly connected and functioning optimally.

By ensuring compatibility with these engines, the 3966805 wiring harness from Cummins provides a reliable solution for maintaining and operating these engines effectively.

Role of Part 3966805 Wiring Harness in Engine Systems

The Part 3966805 Wiring Harness is an integral component in the orchestration of various engine systems, ensuring seamless communication and operation among them.

Integration with Electronic Control Module (ECM) Wiring

The Wiring Harness facilitates the connection between the Electronic Control Module (ECM) and other engine components. It acts as a conduit for data and power, allowing the ECM to monitor and adjust engine performance in real-time. This includes regulating fuel injection, ignition timing, and emissions controls, all of which are vital for optimal engine operation 2.

Engine Control Wiring

In the realm of engine control wiring, the Wiring Harness plays a pivotal role. It connects sensors and actuators to the ECM, enabling the collection of data such as engine temperature, air-fuel ratio, and throttle position. This data is essential for the ECM to make precise adjustments to the engine’s operation, ensuring efficiency and performance 3.

Interaction with Rocker Lever Housing

The Wiring Harness also interfaces with the Rocker Lever Housing, a component that houses various mechanical and electrical elements of the engine. Through this connection, the harness ensures that the signals from the rocker lever mechanisms are accurately transmitted to the ECM. This allows for the fine-tuning of valve operation, which is crucial for engine responsiveness and power delivery.

Conclusion

In summary, the Part 3966805 Wiring Harness is a fundamental element in the engine’s electrical system, bridging the gap between mechanical components and electronic control units. Its role in facilitating communication and power distribution is essential for the harmonious operation of the engine.

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.