Introduction

The Cummins 3967524 Breather Baffle is a critical component in heavy-duty truck engines, designed to enhance engine efficiency and reliability. Understanding its function and maintenance is essential for ensuring the optimal performance of these engines.

Basic Concepts of Breather Baffles

Breather baffles regulate air flow within an engine’s crankcase, managing pressure and preventing contaminant buildup by allowing clean air in while restricting the escape of oil mist and particles 1. This is crucial for maintaining engine health and preventing issues like oil leaks.

Purpose of the Cummins 3967524 Breather Baffle

This Cummins part facilitates air exchange within the crankcase, allowing fresh air to enter while preventing the escape of oil mist and contaminants. This maintains a clean and stable environment within the engine, contributing to its efficient operation 2.

Key Features

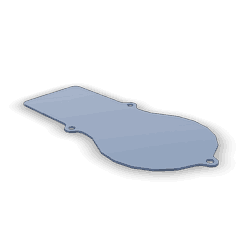

The 3967524 is characterized by its robust design and high-quality materials. It features a baffle plate that effectively separates incoming air from oil mist, enhancing ventilation efficiency. The component is engineered to withstand the demanding conditions of heavy-duty truck operation, ensuring durability and reliability.

Benefits

Using the 3967524 Breather Baffle can improve engine performance and durability by maintaining a clean crankcase environment, reducing the risk of oil contamination and engine wear. Its design also contributes to reduced maintenance requirements, offering long-term value to truck operators 3.

Installation Process

Installing this part requires careful attention to ensure proper function within the engine system. The process involves securing the baffle in the crankcase ventilation system, ensuring a tight seal to prevent air leaks. Following manufacturer guidelines is crucial for a successful installation.

Troubleshooting and Maintenance

Regular inspection and maintenance of the 3967524 are recommended for optimal performance and longevity. Common issues may include blockages or damage to the baffle, affecting the efficiency of the crankcase ventilation system. Troubleshooting involves checking for signs of wear or contamination and addressing any issues promptly.

Cummins Overview

Cummins Inc. is a global leader in power solutions, including engines, filtration, and emission solutions. Known for innovation and quality, Cummins has a strong reputation in the automotive industry for producing reliable and high-performance components.

Compatibility of Cummins Breather Baffle Part 3967524

The 3967524 is compatible with various Cummins engine models, including ISC, ISL, L, QSC, and QSL series. It is designed to manage gas flow within the engine’s crankcase, ensuring efficient ventilation and preventing harmful vapor buildup.

Compatible Engine Models

- ISC Series: ISC CM2150, ISC CM850, ISC8.3 CM2250

- ISL Series: ISL CM2150, ISL9 CM2150 SN, ISL9 CM2250, ISL9.5 CM2880 L138

- L Series: L8.9, L8.9 CM2670 L134C, L8.9 L121, L9 CM2670 L128B, L9.5 L117

- QSC Series: QSC8.3 CM2880 C102, QSC8.3 CM554, QSC8.3 CM850 (CM2850), QSC9 CM2250 / QSL9 CM2250

- QSL Series: QSL8.9 CM2150 L141, QSL9 CM2250, QSL9 CM2350 L102, QSL9 CM554, QSL9 CM850 (CM2850), QSL9.3 CM2880 L113

Role of Part 3967524 Breather Baffle in Engine Systems

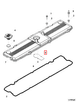

The 3967524 Breather Baffle is vital for maintaining engine efficiency and reliability. Positioned within the valve cover, it manages gas and fluid flow, ensuring optimal engine performance.

Interaction with Valve Cover

Within the valve cover, the Breather Baffle directs crankcase vapors, preventing pressure buildup and allowing controlled vapor release. This maintains a stable environment within the valve cover, reducing oil contamination risk and ensuring smooth operation of valve train components.

The baffle also separates oil mist from crankcase vapors, keeping the valve cover and components clean. This is crucial for engine longevity and efficiency, preventing oil sludge buildup that can decrease performance and increase wear on valve train components.

Conclusion

The Cummins 3967524 Breather Baffle is integral to the efficient operation of heavy-duty truck engines. Its role in managing crankcase vapors and maintaining a clean operating environment underscores its importance in engine maintenance and performance.

-

Lakshminarayanan, P. A., & Nayak, N. S. (2011). Critical Component Wear in Heavy Duty Engines. John Wiley & Sons.

↩ -

Heywood, J. (2019). Internal Combustion Engine Fundamentals. McGraw-Hill Education.

↩ -

Brown Jr, A. (2010). Technologies and Approaches to Reducing the Fuel Consumption of Medium and Heavy-Duty Vehicles. National Academy of Sciences.

↩

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.