This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

The Cummins 3969631 Wiring Harness is a specialized component designed for use in commercial trucks. It serves as a vital part of the vehicle’s electrical system, facilitating the connection between various electrical components and the truck’s power source. This wiring harness is integral to ensuring the reliable operation of the truck’s electrical systems, contributing to overall vehicle performance and safety.

Basic Concepts of Wiring Harnesses

A wiring harness is an assembly of wires, connectors, and sometimes switches and relays that transmit electrical power and signals throughout a vehicle. It consists of multiple wires bundled together, often secured with tape or conduit, to protect the wires from physical damage and environmental factors. Within a vehicle’s electrical system, the wiring harness plays a role by providing a structured and organized method for routing electrical connections, reducing the risk of short circuits and improving the efficiency of electrical signal transmission 1.

Purpose of the 3969631 Wiring Harness

The Cummins 3969631 Wiring Harness is designed to integrate seamlessly with the electrical systems of commercial trucks. It connects various electrical components, such as sensors, lights, and control modules, to the truck’s power source. This integration allows for the efficient distribution of electrical power and signals, ensuring that all electrical systems operate correctly. The harness also plays a role in protecting the wires from physical damage and environmental conditions, contributing to the reliability and durability of the truck’s electrical system.

Key Features

The Cummins 3969631 Wiring Harness is characterized by its robust design and high-quality materials. It is constructed using durable wires and connectors that are resistant to corrosion, abrasion, and extreme temperatures. The harness is also designed with flexibility in mind, allowing it to be routed through tight spaces within the truck’s chassis. Additionally, it features color-coded wires and connectors for easy identification and installation, enhancing both the performance and durability of the electrical system.

Benefits

The Cummins 3969631 Wiring Harness offers several advantages for commercial truck operations. Its robust design and high-quality materials contribute to improved reliability, reducing the likelihood of electrical failures. The efficient distribution of electrical power and signals enhances the overall efficiency of the truck’s electrical system. Furthermore, the harness’s protective features help to ensure the safety of the electrical components, minimizing the risk of short circuits and other electrical hazards.

Installation Process

Installing the Cummins 3969631 Wiring Harness requires careful planning and execution to ensure proper integration with the truck’s electrical system. The process involves identifying the correct routing paths for the harness, securing it in place with ties or conduit, and connecting it to the appropriate electrical components. It is important to follow the manufacturer’s instructions and best practices to avoid damaging the harness or the electrical components. Potential challenges include ensuring that the harness is routed away from moving parts and high-temperature areas to prevent damage 2.

Common Issues and Troubleshooting

Wiring harnesses, including the Cummins 3969631, may encounter issues such as wire damage, connector corrosion, or electrical shorts. Regular inspections can help identify these problems early. Troubleshooting may involve checking for continuity in the wires, cleaning or replacing corroded connectors, and ensuring that all connections are secure. Addressing these issues promptly can help maintain the reliability and safety of the truck’s electrical system.

Maintenance Tips

To ensure the longevity and optimal performance of the Cummins 3969631 Wiring Harness, regular maintenance is recommended. This includes inspecting the harness for signs of wear or damage, ensuring that all connections are secure, and protecting the harness from physical damage and environmental conditions. Additionally, keeping the harness clean and dry can help prevent corrosion and other forms of degradation.

Cummins Overview

Cummins Inc. is a global power leader that designs, manufactures, and distributes engines, filtration, and power generation products. With a history spanning over a century, Cummins has established a strong reputation in the commercial truck industry for producing reliable and high-performance engines and components. The company’s product range includes a variety of engines, powertrains, and aftermarket parts designed to meet the demanding requirements of commercial truck applications 3.

Cummins Wiring Harness 3969631 Compatibility

The Cummins Wiring Harness part number 3969631 is designed to be compatible with a variety of Cummins engines. This wiring harness is a crucial component for ensuring proper electrical connectivity and functionality across different engine models. Here is a detailed look at the engines with which this wiring harness is compatible:

ISB/ISD 6.7 Series

- ISB/ISD 6.7 CM2150 SN

- ISBE CM2150

- ISC CM2150

- ISC8.3 CM2250

- ISL CM2150

- ISL9 CM2150 SN

- ISL9 CM2250

- ISL9.5 CM2880 L138

These engines are part of the ISB/ISD 6.7 series, which are known for their robust performance and reliability. The wiring harness 3969631 is engineered to fit seamlessly with these engines, ensuring that all electrical connections are made correctly and efficiently.

QSC/QSL Series

- QSC9 CM2250/QSL9 CM2250

- QSL8.9 CM2150 L141

- QSL9 CM2250

- QSL9 CM2350 L102

- QSL9 CM850 (CM2850)

The QSC/QSL series engines are another set of models that the wiring harness 3969631 is compatible with. These engines are often used in heavy-duty applications and require a reliable wiring harness to maintain optimal performance. The harness is designed to handle the electrical demands of these engines, ensuring smooth operation and longevity.

Grouping by Engine Series

By grouping the engines into their respective series, it becomes clear that the wiring harness 3969631 is versatile and designed to cater to a wide range of Cummins engines. Whether you are working with the ISB/ISD 6.7 series or the QSC/QSL series, this wiring harness provides a reliable solution for maintaining the electrical integrity of your engine.

Role of Part 3969631 Wiring Harness in Engine Systems

The 3969631 Wiring Harness is an integral component in the electrical system of various engine setups, facilitating the seamless operation of multiple subsystems.

Integration with Brake Systems

In brake systems, the 3969631 Wiring Harness ensures reliable electrical connections between the brake components and the vehicle’s electrical system. It routes power and signals to the brake lights, ensuring they activate promptly when the brake pedal is pressed. Additionally, it supports the functionality of electronic brake systems by providing consistent power supply and data transmission lines necessary for anti-lock braking systems (ABS) and electronic brakeforce distribution (EBD).

Engine Electrical Management

For the engine, the 3969631 Wiring Harness plays a significant role in managing the electrical connections required for optimal performance. It links various sensors, such as the oxygen sensor, throttle position sensor, and engine temperature sensor, to the engine control unit (ECU). This allows the ECU to receive real-time data, enabling it to make precise adjustments to fuel injection, ignition timing, and other critical parameters. The harness also ensures that power is distributed efficiently to components like the fuel pump, ignition coils, and starter motor.

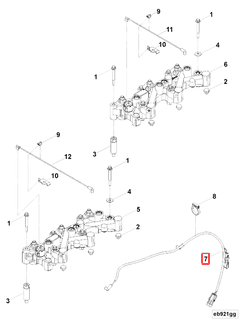

Engine Brake (12V) Kit Compatibility

When integrated with an Engine Brake (12V) Kit, the 3969631 Wiring Harness is responsible for managing the electrical connections that enable the engine brake function. It provides the necessary power and control signals to the actuators and solenoids within the kit. This ensures that the engine brake can engage and disengage smoothly, enhancing vehicle control during descents and reducing wear on the transmission and braking system. The harness also facilitates communication between the engine brake system and the vehicle’s ECU, allowing for coordinated operation with other engine management strategies.

Conclusion

The Cummins 3969631 Wiring Harness is a critical component in the electrical systems of commercial trucks, ensuring reliable and efficient operation of various subsystems. Its robust design, high-quality materials, and compatibility with a wide range of Cummins engines make it an essential part for maintaining the electrical integrity and performance of these vehicles. Regular maintenance and proper installation are key to maximizing the benefits of this Cummins part.

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.