3973511

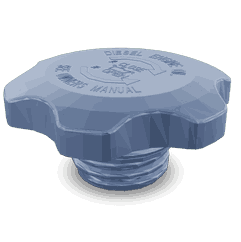

Filler Cap

Cummins®

IN STOCK

More than 10 are currently available

Ships within 1 business day

This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

Introduction

The Cummins 3973511 Filler Cap is a component designed for use in commercial trucks, specifically within the fuel system. Its primary role is to facilitate the addition of fuel to the tank while ensuring that spills and contamination are minimized. This part is integral to maintaining the efficiency and safety of the vehicle’s fuel system 2.

Purpose and Function

The filler cap serves a function in the truck’s fuel system by providing a secure point of entry for refueling. It is engineered to allow fuel to be added to the tank efficiently while preventing spills that could pose safety hazards or environmental risks. Additionally, the cap helps to keep contaminants out of the fuel system, which is important for maintaining engine performance and longevity 3.

Key Features

The Cummins 3973511 Filler Cap is characterized by several key features that enhance its performance and durability. It is constructed from high-quality materials that are resistant to wear and corrosion, ensuring long-term reliability. The design of the cap includes a sealing mechanism that creates a tight fit on the fuel tank, which is important for preventing leaks and maintaining system integrity. Furthermore, the cap is designed to be user-friendly, allowing for easy operation during refueling 4.

Benefits

The use of the Cummins 3973511 Filler Cap offers several benefits. It contributes to improved fuel system integrity by providing a secure and leak-proof connection to the fuel tank. The cap’s design also enhances ease of use, making the refueling process more convenient for operators. Additionally, it is compatible with Cummins fuel tanks, ensuring a proper fit and function within the system 1.

Installation and Usage

Proper installation of the Cummins 3973511 Filler Cap is crucial for optimal performance. The installation process involves securing the cap onto the fuel tank opening, ensuring that it is aligned correctly and tightened to the manufacturer’s specifications. It is important to follow best practices to ensure a secure fit, which includes checking for any damage to the cap or tank opening before installation. During usage, operators should ensure that the cap is properly sealed after refueling to maintain system integrity 2.

Maintenance and Troubleshooting

To ensure the long-term reliability of the Cummins 3973511 Filler Cap, regular maintenance is recommended. This includes inspecting the cap for signs of wear or damage and cleaning it as necessary to remove any buildup that could affect its sealing capability. Common issues that may arise include leaks or difficulty in sealing, which can often be addressed by ensuring the cap is properly aligned and tightened or by replacing worn components 3.

Safety Considerations

When using the Cummins 3973511 Filler Cap, it is important to adhere to safety protocols to prevent accidents and ensure the safe handling of fuel. This includes avoiding static electricity buildup during refueling, which can be a fire hazard, and ensuring that the area is well-ventilated. Additionally, operators should be trained in the proper procedures for installing and maintaining the cap to prevent injuries or damage to the fuel system 4.

Environmental Impact

The Cummins 3973511 Filler Cap plays a role in minimizing the environmental impact of commercial truck operations by preventing fuel spills and ensuring efficient fuel system operation. By maintaining a secure seal on the fuel tank, it helps to reduce the risk of fuel leaks, which can contaminate soil and water sources. Furthermore, efficient fuel system operation contributes to lower emissions, aligning with environmental protection goals 1.

Cummins Overview

Cummins Inc. is a global power leader that designs, manufactures, and distributes engines, filtration, and power generation products. With a history of innovation and a commitment to sustainability, Cummins offers a wide range of products designed to meet the needs of various industries, including commercial trucking. The company’s focus on quality and performance is evident in its product offerings, including the Cummins 3973511 Filler Cap 2.

Cummins Engine Filler Cap Compatibility

The Cummins part 3973511, a filler cap, is designed to fit a variety of Cummins engines. This filler cap is a component for maintaining the integrity of the engine’s fuel system by preventing contamination and ensuring proper fuel vapor management.

6B5.9 and 6C8.3 Engines

The 6B5.9 and 6C8.3 engines are part of the Cummins B-Series family. These engines are known for their durability and efficiency, often used in various industrial and agricultural applications. The filler cap 3973511 is compatible with these engines, ensuring a secure fit and effective sealing 3.

B5.6 CM2670 B152B and B6.7 CM2350 B135B

The B5.6 CM2670 B152B and B6.7 CM2350 B135B engines are also part of the Cummins B-Series. The filler cap 3973511 is engineered to fit these engines, providing a reliable seal that helps maintain the engine’s performance and longevity 4.

B6.7 CM2670 B153B

The B6.7 CM2670 B153B engine is another variant within the B-Series. The filler cap 3973511 is specifically designed to fit this engine, ensuring compatibility and effective sealing 1.

ISB Engines

The ISB (Chrysler) engines, including the ISB CM2150, ISB CM850, ISB/ISD4.5 CM2150 B119, ISB/ISD6.7 CM2150 SN, ISB5.9 CM2880 B110, ISB5.9 CM2880 B140, ISB5.9 CM2880 B149, ISB6.7 CM2250, ISB6.7 CM2350 B101, ISB6.7 G CM2180 B118, and ISBE CM2150, are designed for a range of applications from commercial vehicles to industrial machinery. The filler cap 3973511 is compatible with these engines, providing a secure fit and effective sealing 2.

ISBE Engines

The ISBE CM2150, ISBE CM800, and ISBE4 CM850 engines are part of the Cummins ISBE family. These engines are known for their high performance and efficiency. The filler cap 3973511 is designed to fit these engines, ensuring a reliable seal 3.

ISC Engines

The ISC CM2150, ISC CM850, and ISC8.3 CM2250 engines are part of the Cummins ISC family. These engines are commonly used in various applications, including construction equipment and power generation. The filler cap 3973511 is compatible with these engines, providing a secure fit and effective sealing 4.

ISL Engines

The ISL CM2150, ISL9 CM2150 SN, and ISL9 CM2250 engines are part of the Cummins ISL family. These engines are known for their durability and efficiency, often used in heavy-duty trucks and industrial applications. The filler cap 3973511 is designed to fit these engines, ensuring a reliable seal and effective fuel vapor management 1.

Understanding the Role of Part 3973511 Filler Cap in Engine Systems

The part 3973511 Filler Cap is a component in the orchestration of various engine systems, ensuring the seamless operation and maintenance of the engine. Its role is multifaceted, interfacing with several key components to facilitate efficient engine performance 2.

Integration with the Long Block and Long Block Kit

When installed in a long block or a long block kit, the 3973511 Filler Cap provides a secure point for oil replenishment. This is vital for maintaining the correct oil levels, which are necessary for lubricating moving parts and reducing wear and tear within the engine 3.

Functionality in the Oil Fill Adapter and Oil Fill Arrangement

The filler cap is designed to work in conjunction with the oil fill adapter and the overall oil fill arrangement. It ensures that oil is introduced into the system without contamination, which is key to preserving the integrity of the lubrication system and preventing potential engine damage 4.

Relationship with the Plate Cover and Sensor Kit

In engines where a plate cover is utilized, the filler cap often interfaces with this component to provide access for oil changes and checks. Additionally, when a sensor kit is part of the engine’s design, the filler cap may house or be adjacent to sensors that monitor oil levels and conditions, providing real-time data to the engine’s electronic control unit 1.

Interaction with the Valve Cover and Valve Cover Arrangement

The filler cap is typically mounted on the valve cover, which is a critical part of the engine’s upper end. It not only protects the valvetrain components but also plays a role in managing engine breathability. The filler cap’s location on the valve cover allows for convenient access during maintenance while also contributing to the valve cover arrangement’s overall function 2.

Coordination with the Valve Cover Blowby Sensor Kit

In engines equipped with a valve cover blowby sensor kit, the filler cap may be integrated into the system to allow for the measurement of blowby gases. This is important for assessing the engine’s condition and ensuring that combustion gases are not excessively leaking past the piston rings, which could indicate wear or the need for maintenance 3.

Conclusion

In summary, the 3973511 Filler Cap is a component that, while seemingly simple, plays a significant role in the complex interplay of engine systems. Its proper installation and maintenance are key to the engine’s longevity and performance 4.

-

Simulation and Optimization of Internal Combustion Engines, Zhiyu Han, SAE International, 2022

↩ ↩ ↩ ↩ ↩ -

The Motor Vehicle, TK Garrett, K Newton, W Steeds, Reed Educational and Professional Publishing Ltd, 2001

↩ ↩ ↩ ↩ ↩ ↩ -

Crolla Encyclopedia, David Crolla, Wiley, 2015

↩ ↩ ↩ ↩ ↩ ↩ -

SAE International’s Dictionary for Automotive Engineers, John F Kershaw, SAE International, 2023

↩ ↩ ↩ ↩ ↩ ↩

SPECIFICATIONS

BILL OF MATERIALS

| Name | Quantity | Part Number |

|---|---|---|

| O Ring Seal | 1 | 3973512 |

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.