3973853

Vibration Isolator

Cummins®

AVAILABLE

More than 10 are currently available

Ships within 2-4 business days

This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

Introduction

The Cummins 3973853 Vibration Isolator is a component designed to mitigate the transmission of vibrations from the engine to the truck’s frame and other components. In commercial truck operations, this part plays a significant role in ensuring the smooth and efficient functioning of the vehicle. By reducing vibrations, it contributes to the overall performance, longevity, and comfort of the truck.

Basic Concepts of Vibration Isolators

Vibration isolators are devices used in mechanical systems to reduce the transmission of vibrations from one part of the system to another. They function by absorbing, dampening, or deflecting vibrations, thereby protecting the integrity and performance of the equipment. The principles of vibration isolation involve the use of materials and designs that can absorb kinetic energy and prevent it from being transferred through the system. This is particularly important in maintaining the structural integrity and operational efficiency of mechanical components 1.

Purpose of the 3973853 Vibration Isolator

The Cummins 3973853 Vibration Isolator is specifically designed to reduce the vibrations transmitted from the engine to the truck’s frame and other components. By doing so, it helps in maintaining the structural integrity of the truck, ensuring that the vibrations do not cause undue stress or damage to the vehicle’s components. This reduction in vibration also contributes to a smoother operation of the truck, enhancing both driver comfort and the overall performance of the vehicle.

Key Features

The Cummins 3973853 Vibration Isolator features a design that incorporates high-quality materials to ensure durability and effective performance. Its construction includes robust components that can withstand the rigors of commercial truck operations. Unique characteristics of this isolator include its ability to effectively absorb and dampen vibrations, ensuring that they do not adversely affect the truck’s frame or other components. The design also considers factors such as ease of installation and maintenance, contributing to its overall effectiveness.

Benefits

Using the Cummins 3973853 Vibration Isolator offers several benefits. It contributes to improved ride comfort by reducing the vibrations felt by the driver and passengers. Additionally, it helps in reducing wear and tear on the truck’s components, enhancing the longevity of the mechanical systems. The isolator also plays a role in maintaining engine performance by ensuring that vibrations do not interfere with the operation of the engine and its components.

Installation and Integration

Proper installation and integration of the Cummins 3973853 Vibration Isolator within a truck’s engine system are important for optimal performance. Guidelines for installation include ensuring that the isolator is correctly positioned and securely fastened. It is also important to follow manufacturer recommendations for integration to ensure that the isolator functions as intended within the truck’s engine system.

Troubleshooting and Maintenance

Common issues that may arise with the Cummins 3973853 Vibration Isolator include wear and tear, which can reduce its effectiveness over time. Troubleshooting tips involve inspecting the isolator for signs of damage or wear and addressing any issues promptly. Regular maintenance practices, such as inspections and timely replacements, are important to ensure the longevity and effective performance of the isolator.

Performance Impact

The Cummins 3973853 Vibration Isolator impacts the overall performance of the truck by contributing to fuel efficiency, engine operation, and driver comfort. By reducing vibrations, it helps in maintaining the structural integrity of the truck and ensuring that the engine operates smoothly. Case studies or examples may demonstrate the positive impact of using this isolator in commercial truck operations.

Cummins Corporation

Cummins Corporation, a leader in the automotive and heavy-duty truck industry, is known for its commitment to innovation, quality, and customer satisfaction. The company’s history and role in the industry reflect its dedication to providing high-quality components and solutions that enhance the performance and longevity of commercial vehicles. Cummins’ products, including the 3973853 Vibration Isolator, are designed with a focus on reliability, durability, and effectiveness in real-world applications.

Compatibility

The Cummins part 3973853, a Vibration Isolator, is designed to fit a variety of Cummins engines, providing essential vibration damping and noise reduction. This part is compatible with several engine models, including:

- B5.6 CM2670 B135B

- B6.7 CM2350 B135B

- B6.7 CM2670 B153B

- ISB (Chrysler)

- ISB CM2150

- ISB/ISD4.5 CM2150 B119

- ISB/ISD6.7 CM2150 SN

- ISB5.9 CM2880 B110

- ISB5.9 CM2880 B140

- ISB5.9 CM2880 B149

- ISB6.7 CM2250

- ISB6.7 CM2350 B101

- ISB6.7 G CM2180 B118

- ISBE CM2150

- ISBE CM800

- ISBE4 CM850

- QSB4.5 CM850 (CM2850)

- QSB5.9 CM2880 B115

- QSB6.7 CM2250

- QSB6.7 CM2350 B105

- QSB6.7 CM850 (CM2850)

- QSB6.7 M CM2250

- QSB7 CM2880 B117

The Vibration Isolator part 3973853 is engineered to interface with these engines, ensuring that the vibrations generated by the engine are effectively managed. This helps in maintaining the longevity and efficiency of the engine components by reducing the mechanical stress caused by vibrations. The isolator is strategically placed to absorb and dissipate the vibrations, thereby enhancing the overall performance and reliability of the engine.

By fitting this part into the specified engines, users can expect a reduction in operational noise and an improvement in the comfort of the engine’s environment. This makes the Vibration Isolator a crucial component for maintaining the operational integrity of these engines.

Role of Part 3973853 Vibration Isolator in Engine Systems

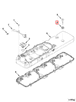

The Part 3973853 Vibration Isolator is an integral component in the arrangement of various engine systems, ensuring optimal performance and longevity. When integrated into the engine’s long block or long block kit, this vibration isolator effectively mitigates the transmission of vibrations from the engine to other components.

In conjunction with the valve cover and its associated components such as the valve and hexagon flange head cap screw, the vibration isolator plays a significant role. It ensures that the vibrations generated during the engine’s operation do not adversely affect the valve cover or the precision of the valve operation. This is particularly important for maintaining the integrity of the seal between the valve cover and the engine block, preventing oil leaks and ensuring efficient engine performance.

Furthermore, the vibration isolator works in tandem with the shoulder isolator cap screw to provide a stable mounting solution. This stability is essential for components that are sensitive to vibrations, such as the valve cover. By reducing the vibrational energy transmitted to these parts, the isolator helps in preserving the tightness of the screws and bolts, which is vital for the overall structural integrity of the engine.

In summary, the Part 3973853 Vibration Isolator is a key component in the engine’s arrangement, enhancing the performance and durability of critical engine parts such as the valve cover, valves, and mounting screws. Its role in vibration management is essential for the smooth and efficient operation of the engine system.

Conclusion

The Cummins 3973853 Vibration Isolator is a critical component in the maintenance and performance of commercial trucks. By effectively reducing engine vibrations, it contributes to the longevity of the vehicle’s components, enhances driver comfort, and ensures efficient engine operation. Proper installation, regular maintenance, and understanding its role within the engine system are key to maximizing the benefits of this part.

-

Kasab, J., & Strzelec, A. (2020). Automotive Emissions Regulations and Exhaust Aftertreatment Systems. SAE International.

↩

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.