The Cummins 4076930 Pressure Switch is a component designed for use in commercial trucks, manufactured by Cummins Inc. This switch is integral to the truck’s operational systems, ensuring that various functions are performed efficiently and reliably.

Basic Concepts of Pressure Switches

A pressure switch is a device that opens or closes an electrical circuit in response to a specific pressure threshold. It operates by using a diaphragm or piston that moves in response to changes in pressure, activating a switch mechanism. Pressure switches are commonly used in automotive systems to monitor and control fluid levels, air pressure, and other critical parameters 1.

Purpose of the Cummins 4076930 Pressure Switch

The Cummins 4076930 Pressure Switch plays a role in the truck’s systems by monitoring and regulating pressure levels within the engine or other components. It ensures that the system operates within safe and efficient parameters by activating or deactivating certain functions based on the pressure readings.

Key Features

The Cummins 4076930 Pressure Switch is characterized by its robust design, which includes a durable housing made from high-quality materials to withstand the harsh conditions of commercial truck environments. It features precise pressure sensing technology, ensuring accurate readings and reliable operation. Additionally, the switch is designed for easy integration into existing truck systems, with straightforward wiring and mounting options.

Benefits

The Cummins 4076930 Pressure Switch offers several advantages, including enhanced system efficiency through precise pressure monitoring and control. It contributes to the overall reliability of the truck by preventing system failures due to pressure irregularities. Furthermore, the switch helps in maintaining optimal performance of the truck’s engine and other components by ensuring they operate within the intended pressure ranges 2.

Installation and Integration

Installing the Cummins 4076930 Pressure Switch involves connecting it to the appropriate pressure lines within the truck’s system and wiring it to the electrical system. It is important to follow the manufacturer’s guidelines for installation to ensure proper function and integration. Considerations for installation include ensuring the switch is securely mounted and that all connections are tight and secure to prevent leaks or electrical issues.

Troubleshooting and Maintenance

Common issues with the Cummins 4076930 Pressure Switch may include inaccurate pressure readings or failure to activate/deactivate as expected. Diagnostic procedures involve checking the electrical connections, ensuring the switch is correctly mounted, and verifying that the pressure lines are free from obstructions or leaks. Regular maintenance includes inspecting the switch for signs of wear or damage and ensuring all connections remain secure.

Safety Considerations

When handling, installing, or maintaining the Cummins 4076930 Pressure Switch, it is important to follow safety guidelines to protect both the user and the component. This includes working in a well-ventilated area, wearing appropriate personal protective equipment, and ensuring the truck’s electrical system is de-energized during installation or maintenance procedures.

Cummins Overview

Cummins Inc. is a global power leader that designs, manufactures, and distributes engines, filtration, and power generation products. With a history spanning over a century, Cummins has established a strong reputation in the commercial truck industry for producing reliable, high-performance components. The company’s product range includes engines, powertrain components, and aftermarket parts, all designed to meet the demanding requirements of commercial transportation 3.

Compatibility with Cummins Engines

The Cummins Pressure Switch part number 4076930 is a critical component in the engine’s fuel and air systems, ensuring proper pressure levels are maintained for optimal engine performance. This part is compatible with a wide range of Cummins engines, including:

-

B3.3, B4.5, B5.6, B6.7: These engines feature the CM2350 and CM2670 series, with part numbers B129B, B152B, B135B, B153B, and B164C. The Pressure Switch 4076930 is integral in these models, ensuring the fuel system operates within the required pressure parameters.

-

D4.0, F2.8, F3.8, F4.5: These engines are part of the CM2620 series, with part numbers D103B, F135B, F120B, F128C, F137B, F139B, and F141C. The Pressure Switch 4076930 is essential for maintaining the correct pressure in the fuel and air systems of these engines.

-

ISB Series: This includes the ISB CM2150, ISB CM550, ISB CM850, ISB/ISD4.5 CM2150 B119, ISB/ISD6.7 CM2150 SN, ISB3.9 CM2220 B107, ISB4.5 CM2350 B104, ISB5.9 CM2880 B110, ISB5.9 CM2880 B140, ISB5.9 CM2880 B149, ISB6.7 CM2250, and ISB6.7 CM2350 B101. The Pressure Switch 4076930 is designed to work seamlessly with these engines, ensuring the pressure levels are monitored and maintained for efficient engine operation.

Role of Part 4076930 Pressure Switch in Engine Systems

The Part 4076930 Pressure Switch is an integral component in various engine systems, ensuring optimal performance and safety. It is strategically positioned to monitor and regulate pressure levels within the engine, interacting with several key components.

Interaction with Lubricating Systems

-

Lubricating Oil Pump: The pressure switch works in conjunction with the lubricating oil pump to maintain the necessary oil pressure. It detects any deviations from the standard pressure levels, signaling the need for adjustments or indicating potential issues within the pump.

-

Lubricating Oil Cooler Module: In systems equipped with a lubricating oil cooler module, the pressure switch helps in regulating the flow of oil to the cooler. This ensures that the oil remains within the optimal temperature range, enhancing engine longevity and efficiency.

-

Oil Cooler and Oil Cooler Housing: The switch monitors the pressure within the oil cooler and its housing, ensuring that the cooling process does not impede the oil flow or create excessive pressure that could damage the system.

-

Oil Filter Cooler Head: By monitoring the pressure at the oil filter cooler head, the switch ensures that the filtration process is efficient and that there are no blockages or restrictions that could affect oil flow.

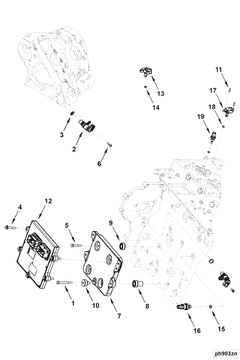

Electrical and Control Integration

-

Engine Control Module (ECM): The pressure switch sends signals to the ECM, providing real-time data on pressure levels. This allows the ECM to make necessary adjustments to engine operations, ensuring that all systems operate within safe parameters.

-

Engine Control Module Location: Typically situated near the engine bay, the ECM relies on accurate data from the pressure switch to execute commands that maintain engine health and performance.

Additional Components

-

Air Pressure Switch: Though distinct, the air pressure switch may interact with the oil pressure switch in systems where air and oil pressures are interrelated, such as in turbocharged engines.

-

Electrical Accessories: The pressure switch is often connected to various electrical accessories that depend on accurate pressure readings to function correctly. This includes sensors and gauges that provide feedback to the driver or automated systems.

Conclusion

In summary, the Cummins 4076930 Pressure Switch is a vital component that ensures the smooth operation of lubricating systems, provides essential data to the ECM, and integrates with various electrical accessories to maintain engine efficiency and safety. Its robust design, precise pressure sensing technology, and compatibility with a wide range of Cummins engines make it an indispensable part of commercial truck systems.

References

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.