This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

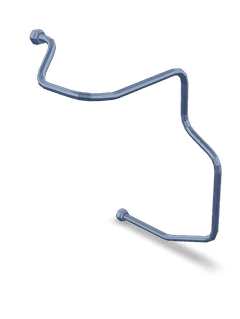

The Compressor Water Outlet Tube (4083500) by Cummins is a component designed for use in heavy-duty truck systems. Its purpose is to facilitate the efficient flow of coolant from the compressor to other parts of the engine cooling system. This tube plays a role in maintaining the optimal operating temperature of the engine, which is important for the performance and longevity of the truck 3.

Basic Concepts

The operation of the Compressor Water Outlet Tube is grounded in the fundamental principles of fluid dynamics and thermal management. This tube is part of the cooling system, where it interacts with other components such as the radiator, thermostat, and water pump. Its role is to direct the flow of coolant, which absorbs heat from the engine and transfers it to the radiator for dissipation 1.

Purpose and Function

In the operation of a truck, the Compressor Water Outlet Tube facilitates the flow of coolant. It ensures that the coolant circulates effectively through the engine, absorbing excess heat and preventing overheating. This contributes to maintaining optimal engine temperature, which is important for efficient engine operation and longevity 3.

Key Features

The 4083500 Compressor Water Outlet Tube is characterized by its robust design and material composition. It is constructed from high-quality materials that offer resistance to corrosion and high temperatures. These attributes enhance its performance and durability, ensuring reliable operation in demanding conditions 2.

Benefits

The 4083500 Compressor Water Outlet Tube offers several advantages. It contributes to improved engine efficiency by ensuring consistent coolant flow and temperature regulation. This reduces the risk of overheating and enhances the overall reliability of the engine cooling system 3.

Installation and Integration

Proper installation of the Compressor Water Outlet Tube involves following manufacturer recommendations and ensuring compatibility with other components in the engine system. It is important to adhere to the specified procedures to guarantee effective integration and operation within the truck’s engine system 3.

Troubleshooting and Maintenance

Common issues with the Compressor Water Outlet Tube may include leaks or blockages. Diagnostic procedures involve inspecting the tube for signs of damage or wear and ensuring that it is securely connected to other components. Regular maintenance practices, such as checking for leaks and ensuring proper coolant levels, are important for ensuring the longevity and optimal performance of the tube 3.

Performance Impact

The Compressor Water Outlet Tube influences the overall performance of the truck by contributing to efficient engine cooling. This can lead to improved fuel efficiency, as a well-regulated engine temperature allows for more efficient combustion. Additionally, effective cooling can extend engine longevity and enhance operational reliability 3.

Cummins Overview

Cummins Inc. is a well-established company in the automotive and heavy-duty truck industry. With a rich history and a diverse product range, Cummins is known for its commitment to quality and innovation. The company’s reputation is built on delivering reliable and high-performance solutions for various applications, including heavy-duty trucks 3.

Compatibility of Compressor Water Outlet Tube (Part 4083500) with Cummins Engines

The Compressor Water Outlet Tube, part number 4083500, manufactured by Cummins, is designed to fit into a variety of Cummins engine models. This part is important for the proper functioning of the engine’s cooling system, ensuring that the compressor section is adequately cooled.

ISM Series Engines

The ISM series engines, including the ISM CM570, ISM CM570/870, ISM CM876, and ISM11 CM876 SN, are compatible with the Compressor Water Outlet Tube part 4083500. These engines are known for their robust performance and reliability in various industrial applications. The ISM series engines are equipped with advanced features that enhance fuel efficiency and reduce emissions, making them a popular choice for heavy-duty applications 3.

M11 Series Engines

The M11 series engines, specifically the M11 CELECT PLUS and M11 MECHANICAL, also utilize the Compressor Water Outlet Tube part 4083500. The M11 CELECT PLUS engine is equipped with advanced electronic controls and a high-efficiency combustion system, providing superior performance and fuel economy. The M11 MECHANICAL engine, on the other hand, offers a more traditional mechanical control system, making it a reliable choice for various applications 3.

QSM11 Series Engine

The QSM11 CM570 engine, part of the QSM11 series, is another engine model that is compatible with the Compressor Water Outlet Tube part 4083500. This engine is designed for high-performance applications, offering a balance of power and efficiency. The QSM11 series engines are known for their durability and reliability, making them suitable for demanding industrial environments 3.

By ensuring that the Compressor Water Outlet Tube part 4083500 is correctly installed in these engines, operators can maintain optimal cooling performance, which is important for the longevity and efficiency of the engine 3.

Role of Part 4083500 Compressor Water Outlet Tube in Engine Systems

The part 4083500 Compressor Water Outlet Tube is a component in the arrangement of engine systems, particularly in the management and regulation of the compressor coolant. This tube facilitates the efficient flow of coolant from the compressor, ensuring that the temperature of the compressor remains within optimal operating ranges 3.

In the context of the compressor coolant system, the Compressor Water Outlet Tube connects to the compressor housing, allowing coolant to exit the compressor after absorbing heat. This process is important for maintaining the integrity and performance of the compressor. The tube is designed to handle the pressure and temperature variations within the coolant system, ensuring a consistent flow that contributes to the overall efficiency of the engine 3.

The integration of the Compressor Water Outlet Tube within the engine system also involves interaction with other components such as the thermostat and radiator. The coolant, after passing through the compressor, typically flows to the radiator where it is cooled before being recirculated. This continuous cycle is fundamental to the thermal management of the engine, preventing overheating and ensuring longevity of the compressor and other engine components 3.

Furthermore, the design of the Compressor Water Outlet Tube allows for easy maintenance and replacement, which is beneficial for routine engine servicing. Its placement within the engine bay is strategic, providing accessibility while ensuring it remains protected from external contaminants and damage 3.

Conclusion

In summary, the Compressor Water Outlet Tube plays a role in the thermal regulation of engine systems by efficiently managing the flow of compressor coolant, thereby contributing to the sustained performance and reliability of the engine 3.

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.