4330744

Tur Oil Drain Tube

Cummins®

IN STOCK

More than 10 are currently available

Ships within 1 business day

This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

Introduction

The 4330744 Tur Oil Drain Tube, manufactured by Cummins, is a component designed to facilitate the maintenance and operation of heavy-duty trucks. It plays a role in the oil drainage system, which is integral to ensuring engine longevity and performance. Proper oil drainage is vital for removing contaminants and maintaining the viscosity of the oil, which in turn supports efficient engine operation 1.

Function and Operation

The Tur Oil Drain Tube functions within the engine’s oil system by providing a pathway for the removal of used oil. This process involves the tube connecting to the oil pan, allowing old oil to be efficiently drained out during maintenance intervals. Efficient oil drainage is important for engine health, as it helps prevent the buildup of sludge and contaminants that can lead to engine wear and reduced performance 2.

Key Features

The Tur Oil Drain Tube is constructed from materials that enhance its durability and efficiency. Its design includes features that ensure a secure fit and reliable performance. These may encompass a robust material composition resistant to corrosion and high temperatures, as well as design elements that facilitate easy installation and maintenance. Unique attributes of this part may include a streamlined shape for optimal flow and a secure locking mechanism to prevent leaks.

Benefits of Using the Tur Oil Drain Tube

Incorporating the Tur Oil Drain Tube into heavy-duty truck maintenance routines offers several advantages. These include improved engine performance due to more efficient oil changes, extended engine life from reduced contamination, and ease of maintenance thanks to its design. Additionally, using this tube can lead to potential cost savings over time by minimizing the risk of engine damage from inadequate oil drainage 3.

Installation and Maintenance

Proper installation of the Tur Oil Drain Tube involves ensuring it is securely attached to the oil pan and that all connections are tight to prevent leaks. Routine maintenance checks should include inspecting the tube for signs of wear, corrosion, or damage. Regular maintenance helps ensure the tube remains in optimal working condition, thereby supporting the overall efficiency of the oil drainage system.

Troubleshooting Common Issues

Common problems associated with oil drain tubes can include leaks, blockages, or damage from wear and tear. These issues may arise from improper installation, material degradation, or physical damage. A step-by-step troubleshooting guide can help mechanics and fleet operators address these problems effectively. Preventive measures, such as regular inspections and maintenance, can help avoid future complications.

Cummins: A Brief Overview

Cummins Inc. is a leader in the diesel engine and related technologies market, with a history of innovation and a commitment to providing reliable and high-quality components. The company offers a wide range of products designed to meet the needs of the automotive industry, emphasizing the importance of using manufacturer-recommended parts for maintenance and repair to ensure compatibility and performance.

Compatibility with Cummins Engines

The 4330744 Tur Oil Drain Tube is designed to fit seamlessly with several Cummins engine models, including the ISX15 CM2250, ISX15 CM2350 X101, and QSX15 CM2250 ECF. Its precision fit ensures optimal performance and longevity of the engine by facilitating the effective drainage of lubricating oil, which is essential for preventing oil contamination and maintaining engine health.

Role in Engine Systems

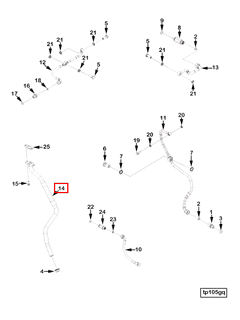

The 4330744 Tur Oil Drain Tube is an essential component in the efficient operation of engine systems, particularly when integrated with plumbing and turbocharger components.

In the context of plumbing, the Tur Oil Drain Tube facilitates the controlled and efficient drainage of oil from the turbocharger system. This is important for maintaining the cleanliness and integrity of the oil, which in turn ensures that the lubrication system operates effectively. Proper drainage prevents oil contamination and reduces the risk of sludge buildup, which can impair the performance of both the turbocharger and the engine.

When considering the turbocharger, the Tur Oil Drain Tube plays a significant role in managing the oil that lubricates the turbocharger’s moving parts. The turbocharger operates at high speeds and temperatures, making consistent and reliable lubrication essential. The Tur Oil Drain Tube ensures that excess oil is promptly removed from the turbocharger housing, preventing oil starvation and ensuring that the turbocharger remains well-lubricated. This not only enhances the turbocharger’s efficiency but also extends its operational lifespan by reducing wear and tear on its components.

Conclusion

In summary, the 4330744 Tur Oil Drain Tube is a vital link in the chain of components that ensure the turbocharger and associated plumbing systems function smoothly and reliably. Its role in oil management is fundamental to the overall health and performance of the engine system.

-

Brach, R. Matthew. SAE International’s Dictionary of Vehicle Accident Reconstruction and Automotive Safety. SAE International, 2023.

↩ -

Xin, Qianfan. Diesel Engine System Design. Woodhead Publishing Limited, 2011.

↩ -

Richards, Paul, and Jim Barker. Automotive Fuels Reference Book. SAE International, 2023.

↩

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.