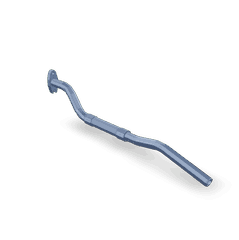

4330989

Turbo Oil Drain Tube

Cummins®

AVAILABLE

10 are currently available

Ships within 2-4 business days

This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

The Cummins 4330989 Turbo Oil Drain Tube is a component designed for the maintenance and operation of heavy-duty trucks. Its purpose is to facilitate the drainage of oil from the turbocharger, which is vital for maintaining the efficiency and longevity of the turbocharger and, by extension, the overall performance of the truck’s engine.

Basic Concepts of Turbo Oil Drain Tubes

Turbo oil drain tubes operate on the principle of managing oil flow within the turbocharger system. These tubes allow for the efficient drainage of oil that has lubricated the turbocharger’s moving parts. Proper oil management is crucial for maintaining the turbocharger’s efficiency and extending its operational life. Without effective oil drainage, oil can accumulate, leading to increased temperatures and potential damage to the turbocharger 1.

Purpose and Role in Truck Operation

The Cummins 4330989 Turbo Oil Drain Tube plays a specific role in the operation of a truck by ensuring that oil is properly drained from the turbocharger. This drainage is important for preventing oil buildup, which can lead to overheating and reduced efficiency. By facilitating the drainage process, the tube contributes to maintaining optimal turbocharger performance and, consequently, enhances the overall engine performance of the truck 2.

Key Features

The Cummins 4330989 Turbo Oil Drain Tube is characterized by its robust design and the materials used in its construction. These features are intended to enhance its performance and durability. The tube is engineered to withstand the high temperatures and pressures associated with turbocharger operation, ensuring reliable performance over time.

Benefits

Using the Cummins 4330989 Turbo Oil Drain Tube offers several benefits. It contributes to improved turbocharger efficiency by ensuring proper oil drainage, which helps maintain optimal operating temperatures. Additionally, it reduces maintenance requirements by minimizing the risk of oil-related issues within the turbocharger. Enhanced engine reliability is another benefit, as the tube plays a role in preventing potential damage caused by oil accumulation 3.

Installation Process

Installing the Cummins 4330989 Turbo Oil Drain Tube requires careful attention to detail to ensure optimal performance and longevity. The process involves securing the tube in place within the turbocharger system, ensuring that it is properly aligned and sealed to prevent oil leaks. Following manufacturer guidelines and best practices during installation is important for achieving the desired outcomes.

Troubleshooting Common Issues

Common issues with turbo oil drain tubes may include oil leaks or blockages. Troubleshooting these problems involves inspecting the tube for signs of damage or wear, ensuring that it is properly installed, and addressing any obstructions that may be preventing proper oil drainage. Regular maintenance and inspections can help identify and resolve these issues promptly.

Maintenance Tips

To ensure the longevity and performance of the Cummins 4330989 Turbo Oil Drain Tube, regular maintenance is recommended. This includes inspecting the tube for signs of wear or damage, cleaning it to remove any debris or buildup, and replacing it according to manufacturer guidelines or when signs of deterioration are observed. Adhering to these maintenance practices can help maintain the tube’s effectiveness over time.

Cummins Overview

Cummins Inc. is a well-established company in the automotive industry, known for its wide range of products and strong reputation for quality and reliability. The company’s history of innovation and commitment to excellence is reflected in its product offerings, including the Cummins 4330989 Turbo Oil Drain Tube. This background provides context for the quality and reliability associated with Cummins products.

Turbo Oil Drain Tube (Part 4330989) Compatibility with Cummins Engines

The Turbo Oil Drain Tube, identified by the part number 4330989, is a critical component in the maintenance and operation of several Cummins engine models. This part is designed to facilitate the drainage of oil from the turbocharger, ensuring that the system operates efficiently and without contamination.

ISX12 CM2350 X102 and ISX12/ISX11.9 CM2250

The Turbo Oil Drain Tube is compatible with the ISX12 CM2350 X102 and ISX12/ISX11.9 CM2250 engines. These engines are part of Cummins’ lineup of high-performance, heavy-duty diesel engines, known for their durability and reliability in demanding applications. The part number 4330989 ensures that the oil drain process is seamless, preventing oil from accumulating in the turbocharger and potentially causing damage.

QSX11.9 CM2250 ECF

Similarly, the Turbo Oil Drain Tube is also suitable for the QSX11.9 CM2250 ECF engine. This engine is designed for applications that require robust performance and efficiency. The part number 4330989 is engineered to fit precisely, ensuring that the oil drainage is effective and that the turbocharger operates within optimal parameters.

By using the Turbo Oil Drain Tube (part 4330989) in these engines, maintenance personnel can ensure that the turbocharger is free from oil accumulation, which can lead to reduced efficiency and potential damage over time. This part is a testament to Cummins’ commitment to providing high-quality components that enhance the performance and longevity of their engines.

Role of Part 4330989 Turbo Oil Drain Tube in Engine Systems

The Turbo Oil Drain Tube, identified by part number 4330989, is an essential component in the efficient operation of turbocharged engine systems. This component is integral to the plumbing system of the turbocharger, ensuring the proper circulation and drainage of oil within the turbo system.

Integration with Turbocharger

In turbocharged engines, the turbocharger operates at extremely high speeds, generating significant heat. The Turbo Oil Drain Tube facilitates the return of oil from the turbocharger to the engine’s lubrication system. This process is vital for maintaining the turbocharger’s temperature within operational limits and ensuring its longevity.

Function within the Plumbing System

The Turbo Oil Drain Tube is a key element in the engine’s oil management system. It connects the turbocharger to the engine’s oil return path, allowing used oil to be efficiently drained away. This drainage is essential for preventing oil buildup, which could lead to increased pressure and potential damage to the turbocharger.

Supporting Engine Performance

By ensuring a consistent flow of oil to and from the turbocharger, the Turbo Oil Drain Tube supports the overall performance and reliability of the engine. It helps in maintaining the correct oil levels and pressure, which are necessary for the turbocharger to function optimally. This, in turn, contributes to the engine’s power output and efficiency.

Maintenance and Efficiency

Regular inspection and maintenance of the Turbo Oil Drain Tube are recommended to ensure it remains free from blockages or leaks. A well-maintained drain tube contributes to the turbocharger’s efficiency and the engine’s overall performance, reducing the risk of unexpected failures.

Conclusion

In summary, the Turbo Oil Drain Tube (part 4330989) plays a significant role in the turbocharger’s oil management system, directly influencing the engine’s performance and reliability. Its proper installation, maintenance, and function are critical for the efficient operation of heavy-duty trucks equipped with Cummins engines.

-

Mohamed ElSayed PE, Fundamentals of Integrated Vehicle Realization, SAE International, 2017.

↩ -

Andrew Brown Jr, Technologies and Approaches to Reducing the Fuel Consumption of Medium and Heavy-Duty Vehicles, National Academy of Sciences, 2010.

↩ -

Robert Huzij, Angelo Spano, Sean Bennett, Modern Diesel Technology: Heavy Equipment Systems, Cengage Learning, 2019.

↩

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.