4331306

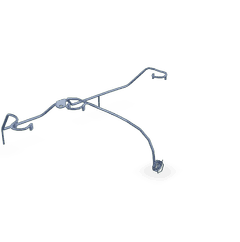

Wiring Harness

Cummins®

IN STOCK

More than 10 are currently available

Ships within 1 business day

This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

Introduction

The Cummins 4331306 Wiring Harness is a specialized component designed for use in commercial trucks. It serves as a vital part of the vehicle’s electrical system, facilitating the connection between various electrical components and the truck’s power source. This wiring harness ensures that electrical signals and power are efficiently distributed throughout the truck, contributing to its overall operation and performance.

Basic Concepts of Wiring Harnesses

A wiring harness is an assembly of wires, connectors, and sometimes switches that transmit electrical power and signals between different components of a vehicle. It typically includes insulated wires bundled together, connectors for joining wires, and protective housing to shield the wires from physical damage and environmental factors. Within a vehicle’s electrical system, the wiring harness plays a role in ensuring that all electrical components receive the necessary power and signals to function correctly 1.

Purpose of the 4331306 Wiring Harness

The Cummins 4331306 Wiring Harness is specifically designed to integrate with the electrical systems of commercial trucks. It connects various electrical components, such as sensors, lights, and control units, to the truck’s power source. This harness plays a role in facilitating communication between the truck’s engine control module and other electronic systems, ensuring that all components operate in unison. Its design allows for efficient power distribution and signal transmission, contributing to the truck’s overall performance and reliability 2.

Key Features

The Cummins 4331306 Wiring Harness is characterized by its robust design and high-quality materials. It is constructed using durable, weather-resistant materials to withstand the harsh conditions often encountered in commercial trucking. The harness features precise wiring and secure connections, ensuring reliable performance. Additionally, its design includes protective measures to shield the wires from abrasion and environmental factors, enhancing its durability and longevity 3.

Benefits

The Cummins 4331306 Wiring Harness offers several advantages for truck operations. It contributes to improved efficiency by ensuring that electrical power and signals are transmitted with minimal loss. This results in more reliable operation of the truck’s electrical systems. Additionally, the harness’s robust construction and protective features enhance its durability, reducing the likelihood of electrical failures and the need for frequent repairs. Furthermore, by ensuring reliable electrical connections, the harness plays a role in enhancing the safety of truck operations.

Installation and Integration

Installing the Cummins 4331306 Wiring Harness requires careful attention to ensure proper integration with the truck’s electrical system. It is important to follow the manufacturer’s guidelines for installation to ensure that all connections are secure and that the harness is correctly positioned within the truck. Specific requirements may include ensuring that the harness is routed away from heat sources and moving parts to prevent damage. Additionally, it is crucial to verify that all connections are correctly made to avoid electrical issues.

Troubleshooting and Maintenance

Common issues with the Cummins 4331306 Wiring Harness may include loose connections, damaged wires, or corrosion at connection points. Troubleshooting these problems involves inspecting the harness for visible signs of damage, ensuring that all connections are secure, and testing the electrical continuity of the wires. Regular maintenance practices, such as cleaning connection points and inspecting the harness for signs of wear or damage, can help ensure its longevity and optimal performance.

Safety Considerations

When working with the Cummins 4331306 Wiring Harness, it is important to observe electrical safety practices. This includes ensuring that the truck’s battery is disconnected before beginning any work on the harness to prevent electrical shocks. Additionally, it is crucial to use the appropriate tools and personal protective equipment when handling the harness to avoid injury. Following these safety protocols helps ensure a safe working environment.

Environmental Impact

The production, use, and disposal of the Cummins 4331306 Wiring Harness have environmental considerations. Cummins Inc. is committed to minimizing its environmental footprint through various initiatives, including the use of recyclable materials in the manufacturing process and efforts to reduce waste. Additionally, proper disposal and recycling of the harness at the end of its life cycle can help mitigate its environmental impact.

Cummins Overview

Cummins Inc. is a global power leader that designs, manufactures, and distributes engines, filtration, and power generation products. With a history spanning over a century, Cummins is known for its commitment to innovation, quality, and customer satisfaction. The company offers a wide range of products for various industries, including automotive, construction, and power generation, demonstrating its versatility and expertise in the field.

Conclusion

The Cummins 4331306 Wiring Harness is a critical component in the electrical systems of commercial trucks, ensuring efficient power distribution and signal transmission. Its robust design, high-quality materials, and protective features contribute to the reliability and safety of truck operations. Proper installation, maintenance, and adherence to safety protocols are essential for maximizing the performance and longevity of this Cummins part.

-

Andrew Brown Jr, Technologies and Approaches to Reducing the Fuel Consumption of Medium and Heavy-Duty Vehicles, National Academy of Sciences, 2010.

↩ -

Willard W. Pulkrabek, Engineering Fundamentals of the Internal Combustion Engine, Pearson Education, 2014.

↩ -

Klaus Mollenhauer and Helmut Tschoeke, Handbook of Diesel Engines, Springer, 2010.

↩

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.