This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

The Cummins 4924911 Metal Enclosure is a component designed to safeguard sensitive parts within commercial trucks. Metal enclosures are protective housings made from metal, used extensively in the automotive industry to shield various components from environmental factors. In commercial truck operations, such enclosures play a significant role in maintaining the integrity and functionality of critical systems 4.

Basic Concepts of Metal Enclosures

Metal enclosures are protective housings constructed from materials like steel, aluminum, and various alloys. These materials are chosen for their durability, resistance to corrosion, and ability to withstand harsh environmental conditions. The manufacturing processes for metal enclosures typically involve cutting, bending, welding, and finishing to create a robust and reliable protective structure 1.

Purpose of the 4924911 Metal Enclosure

The Cummins 4924911 Metal Enclosure is specifically designed to protect sensitive truck components from environmental factors such as dust, moisture, and physical impacts. By providing a barrier against these elements, the enclosure helps maintain the operational efficiency and longevity of the enclosed parts, ensuring consistent performance in various operating conditions 2.

Key Features

The Cummins 4924911 Metal Enclosure features a robust design constructed from high-quality materials. It includes sealing mechanisms to prevent the ingress of dust and moisture, and additional protective elements to enhance its effectiveness. These features work together to provide comprehensive protection for the enclosed components, ensuring they remain in optimal condition 3.

Benefits

The Cummins 4924911 Metal Enclosure offers several benefits, including enhanced durability of the enclosed components, improved reliability of truck operations, and potential cost savings through reduced maintenance and repair needs. By protecting sensitive parts from environmental damage, the enclosure contributes to the overall efficiency and longevity of the truck 4.

Installation Considerations

Proper installation of the Cummins 4924911 Metal Enclosure is crucial for ensuring optimal protection and functionality. Guidelines for installation include correct placement and securing methods to maintain the integrity of the enclosure. Attention to these details helps ensure that the enclosure effectively safeguards the components it is designed to protect 1.

Troubleshooting and Maintenance

Common issues with the Cummins 4924911 Metal Enclosure may include damage to the sealing mechanisms or corrosion of the metal. Troubleshooting steps involve inspecting the enclosure for any signs of wear or damage and addressing these issues promptly. Regular maintenance, including inspections and cleaning, helps ensure the longevity and effectiveness of the enclosure 2.

Environmental and Operational Impact

The Cummins 4924911 Metal Enclosure contributes to the overall environmental and operational efficiency of the truck by protecting internal components from damage. This protection leads to better performance and reduced downtime, as the enclosed parts are less likely to fail due to environmental factors. The enclosure plays a role in maintaining the truck’s operational efficiency and reliability 3.

Cummins Overview

Cummins Inc. is a leading manufacturer in the commercial truck industry, known for its commitment to quality and innovation. With a diverse product range that includes engines, filtration systems, and aftermarket parts, Cummins has established a reputation for producing reliable and high-performance components. The company’s dedication to excellence is evident in its continued investment in research and development, ensuring that its products meet the evolving needs of the industry 4.

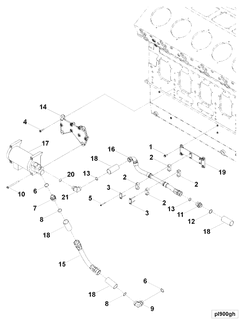

Role of Part 4924911 Metal Enclosure in Engine Systems

The 4924911 Metal Enclosure is integral to the effective operation and protection of various engine components. It is designed to encase and safeguard sensitive parts, ensuring their longevity and optimal performance.

Integration with Engine Components

-

Arrangement: The Metal Enclosure plays a significant role in the systematic arrangement of engine components. By providing a structured housing, it ensures that parts such as the Engine Lubrication Primer and Current Support Control are positioned correctly, facilitating efficient operation and maintenance.

-

Engine Lubrication Primer: This component is essential for preparing the engine for start-up by ensuring all moving parts are adequately lubricated. The Metal Enclosure protects the primer from external contaminants and physical damage, thereby maintaining its efficiency and reliability.

-

Current Support Control: Efficient electrical management is vital for the engine’s performance. The Metal Enclosure houses the Current Support Control, shielding it from environmental factors that could interfere with its operation. This protection ensures stable and consistent current supply to the engine’s electrical components.

-

Primer: Similar to the Engine Lubrication Primer, the primer system benefits from the enclosure by being safeguarded against wear and tear. This ensures that the primer can consistently deliver the necessary fuel or oil to the engine, promoting smooth start-ups and reliable operation.

-

Engine Lubricating System: The lubricating system is paramount for reducing friction and wear within the engine. The Metal Enclosure provides a secure environment for the lubricating components, ensuring they remain clean and functional. This, in turn, enhances the overall efficiency and durability of the engine.

Conclusion

In summary, the Cummins 4924911 Metal Enclosure is a fundamental component that enhances the protection and performance of various engine systems, contributing to the engine’s reliability and efficiency. Proper installation, regular maintenance, and prompt troubleshooting are essential to ensure the enclosure’s effectiveness and the longevity of the enclosed components.

-

Bonnick, A., & Newbold, D. (2011). A Practical Approach to Motor Vehicle Engineering and Maintenance, Third Edition. Elsevier Ltd.

↩ ↩ -

Richards, P., & Barker, J. (2023). Automotive Fuels Reference Book. SAE International.

↩ ↩ -

Giles, T. (2019). Automotive Engines Diagnosis Repair and Rebuilding. Cengage Learning.

↩ ↩ -

Xin, Q. (2011). Diesel Engine System Design. Woodhead Publishing Limited.

↩ ↩ ↩

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.