4934545

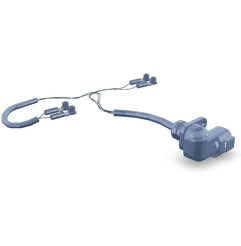

Wiring Harness

Cummins®

IN STOCK

More than 10 are currently available

Ships within 1 business day

This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

Introduction

The Cummins 4934545 Wiring Harness is a specialized component designed for use in commercial trucks. Its purpose is to facilitate the electrical connections necessary for the operation of various truck systems. This part plays a role in ensuring that electrical signals and power are efficiently distributed throughout the vehicle, contributing to the overall functionality and performance of the truck.

Basic Concepts of Wiring Harnesses

A wiring harness is an assembly of wires, connectors, and sometimes switches and relays that transmit electrical power and signals between different components of a vehicle. It consists of insulated wires bundled together and often secured with tape, conduit, or a cable tray. The primary function of a wiring harness is to organize and protect the electrical connections, reducing the risk of short circuits and ensuring reliable operation of the vehicle’s electrical systems 1.

Role of the 4934545 Wiring Harness in Truck Operation

The Cummins 4934545 Wiring Harness is integral to the operation of commercial trucks. It connects various electrical components, such as sensors, actuators, and control modules, allowing them to communicate and function together. This harness plays a role in the truck’s electrical system by providing the necessary connections for engine management, transmission control, braking systems, and other critical functions. Its design ensures that all electrical components receive the correct voltage and signals, contributing to the truck’s overall performance and efficiency 2.

Key Features

The Cummins 4934545 Wiring Harness is characterized by several key features that enhance its performance and durability. It is constructed using high-quality materials that are resistant to wear, corrosion, and environmental factors commonly encountered in commercial truck operations. The design of the harness includes robust connectors and terminals that ensure secure and reliable connections. Additionally, the harness is engineered to withstand the vibrations and harsh conditions typical of heavy-duty truck use, ensuring long-term reliability.

Benefits

The Cummins 4934545 Wiring Harness offers several advantages for truck operations. Its high-quality construction and design contribute to improved reliability, reducing the likelihood of electrical failures. The efficient distribution of electrical power and signals enhances the overall efficiency of the truck’s systems. Furthermore, the harness plays a role in safety by ensuring that all electrical components function correctly, which is vital for the safe operation of the vehicle.

Troubleshooting and Maintenance

Common issues with the Cummins 4934545 Wiring Harness may include loose connections, damaged wires, or corroded terminals. Diagnosing problems typically involves inspecting the harness for visible signs of damage, testing electrical connections for continuity, and using diagnostic tools to identify any faults in the system. Regular maintenance practices, such as cleaning connectors, checking for wear and tear, and ensuring all connections are secure, can help ensure the longevity and optimal performance of the wiring harness.

About Cummins

Cummins Inc. is a global power leader that designs, manufactures, and distributes engines, filtration, and power generation products. With a history spanning over a century, Cummins has established a reputation for producing high-quality automotive components, particularly for heavy-duty trucks. The company is known for its commitment to innovation, reliability, and customer satisfaction, making it a trusted name in the automotive industry.

Cummins Wiring Harness 4934545 Compatibility

The Cummins Wiring Harness part number 4934545 is designed to be compatible with a range of Cummins engines. Here’s a breakdown of its compatibility:

ISC Series Engines

- ISC CM2150

- ISC8.3 CM2250

The ISC series engines, including the ISC CM2150 and ISC8.3 CM2250, are typically used in a variety of applications, from construction equipment to marine vessels. The wiring harness 4934545 is engineered to fit these engines, ensuring seamless electrical connections and reliable performance.

ISL Series Engines

- ISL CM2150

- ISL9 CM2250

The ISL series engines, such as the ISL CM2150 and ISL9 CM2250, are known for their robust performance and efficiency. The wiring harness 4934545 is specifically designed to interface with these engines, providing the necessary electrical connections for optimal operation.

QSC and QSL Series Engines

- QSC9 CM2250/QSL9 CM2250

- QSL9 CM2250

- QSL9 CM2350 L102

The QSC and QSL series engines, including the QSC9 CM2250/QSL9 CM2250, QSL9 CM2250, and QSL9 CM2350 L102, are often found in heavy-duty applications such as trucks and industrial machinery. The wiring harness 4934545 is compatible with these engines, ensuring that all electrical components are properly connected and functioning as intended.

Role of Part 4934545 Wiring Harness in Engine Systems

The 4934545 Wiring Harness is an integral component that facilitates the electrical connectivity within various engine systems. It is meticulously designed to interface with several key components, ensuring seamless operation and communication between them.

Integration with Electronic Control Module (ECM)

The 4934545 Wiring Harness is primarily responsible for connecting the Electronic Control Module (ECM) to other engine components. This harness ensures that the ECM receives accurate data from sensors and transmits control signals to actuators, thereby maintaining optimal engine performance. The harness routes power and data signals to and from the ECM, allowing it to monitor and adjust engine parameters in real-time.

Connection to Rocker Lever Housing

Another significant role of the 4934545 Wiring Harness is its connection to the Rocker Lever Housing. This housing often contains various sensors and switches that monitor the position and operation of the rocker arms. The wiring harness provides the necessary electrical pathways for these sensors to communicate with the ECM, ensuring that the valve timing and lift are precisely controlled. This integration is essential for maintaining engine efficiency and responsiveness.

Electronic Control Module Wiring

The harness also plays a pivotal role in the overall Electronic Control Module Wiring system. It acts as a central conduit, linking the ECM to multiple subsystems within the engine. This includes fuel injectors, ignition coils, and various solenoids. By providing a reliable and organized pathway for electrical signals, the harness helps in reducing electromagnetic interference and ensuring that all components operate in harmony.

Comprehensive System Integration

In summary, the 4934545 Wiring Harness is a vital component that ensures the electrical integrity and communication within the engine system. Its role extends beyond simple connectivity; it is the backbone that supports the complex interactions between the ECM, Rocker Lever Housing, and other critical engine components. This integration is essential for the engine’s overall performance, efficiency, and reliability.

Conclusion

The Cummins 4934545 Wiring Harness is a critical component in the electrical system of commercial trucks, ensuring efficient and reliable operation of various engine systems. Its high-quality construction, robust design, and compatibility with a range of Cummins engines make it an essential part for maintaining the performance and safety of heavy-duty vehicles.

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.