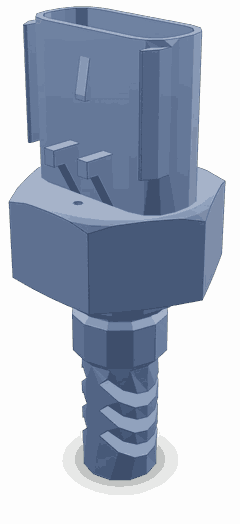

4955125

Humidity Sensor

Cummins®

IN STOCK

More than 10 are currently available

Ships within 1 business day

This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

Introduction

The Cummins 4955125 Humidity Sensor is designed to monitor and report humidity levels within the engine compartment of commercial trucks. This part provides accurate humidity data to optimize engine performance and ensure efficient operation. Its significance in commercial truck operations is attributed to its contribution to better fuel efficiency, enhanced engine performance, and improved maintenance practices 1.

Basic Concepts of Humidity Sensors

A humidity sensor measures the amount of moisture in the air, operating on the principle of capacitance. The sensor’s ability to hold an electrical charge changes with varying humidity levels, which is then converted into a readable measurement. Humidity sensors are vital in environments where moisture levels can affect performance and efficiency, such as in the engine compartments of commercial trucks 2.

Role of the 4955125 Humidity Sensor in Truck Operations

The Cummins 4955125 Humidity Sensor provides real-time humidity data to the engine control unit (ECU), allowing for adjustments to the engine’s operation, such as optimizing fuel injection and air intake, based on current humidity conditions. This sensor is integrated with the truck’s electronic systems to ensure efficient engine operation under varying environmental conditions 3.

Key Features of the 4955125 Humidity Sensor

The primary features of the Cummins 4955125 Humidity Sensor include high accuracy in humidity measurement, rapid response time to changes in humidity, and robust durability to withstand harsh conditions within a truck’s engine compartment. The sensor also incorporates advanced technological aspects such as self-calibration capabilities and resistance to contamination, ensuring reliable performance over time.

Benefits of Using the 4955125 Humidity Sensor

The advantages of using the Cummins 4955125 Humidity Sensor include improved engine performance through optimized fuel injection and air intake, enhanced fuel efficiency by ensuring the engine operates under ideal conditions, and better overall truck maintenance through the provision of accurate humidity data for diagnostic purposes.

Installation and Integration

Installing the Cummins 4955125 Humidity Sensor involves mounting it in a location within the engine compartment where it can accurately measure humidity levels. Integration with the truck’s systems requires connecting the sensor to the ECU, ensuring that the sensor’s data is correctly interpreted and used for engine adjustments. It is important to follow manufacturer guidelines during installation to ensure proper function and integration.

Troubleshooting Common Issues

Common problems with the Cummins 4955125 Humidity Sensor include inaccurate readings, sensor malfunction, and integration issues with the ECU. Potential causes for these problems can range from sensor contamination to electrical connection issues. Recommended troubleshooting steps include checking the sensor for contamination, ensuring proper electrical connections, and verifying the sensor’s calibration.

Maintenance Tips

Best practices for maintaining the Cummins 4955125 Humidity Sensor to ensure longevity and optimal performance include regular checks for contamination or damage, calibration according to manufacturer recommendations, and ensuring that the sensor’s mounting location remains clean and unobstructed. These practices help maintain the sensor’s accuracy and reliability over time.

Impact on Engine Performance

The Cummins 4955125 Humidity Sensor contributes to engine performance by providing data that allows the ECU to make real-time adjustments to fuel injection and air intake based on humidity levels. This can lead to improvements in fuel consumption, emission levels, and overall engine efficiency, demonstrating the sensor’s role in enhancing the operational effectiveness of commercial trucks.

Cummins: A Brief Overview

Cummins is a manufacturer with a rich history and expertise in engine technology. The company is committed to innovation and quality in the automotive industry, offering a wide range of products designed to meet the demanding requirements of commercial vehicle operations. Cummins’ dedication to advancing engine technology is evident in their development of components like the 4955125 Humidity Sensor, which plays a role in optimizing engine performance and efficiency.

Cummins Humidity Sensor 4955125 Compatibility

The Cummins Humidity Sensor, part number 4955125, is designed to integrate seamlessly with a range of Cummins engines, ensuring optimal performance and reliability. This sensor is crucial for maintaining the engine’s efficiency by monitoring and regulating humidity levels within the engine’s operating environment.

B5.9 GAS PLUS CM556 and L GAS PLUS CM556

The B5.9 GAS PLUS CM556 and L GAS PLUS CM556 engines benefit from the humidity sensor’s precise monitoring capabilities. These engines, known for their robust performance in various applications, rely on accurate environmental data to maintain peak operational efficiency. The sensor’s integration into these models ensures that humidity levels are kept within optimal ranges, preventing potential issues such as corrosion and component degradation.

C GAS PLUS CM556

Similar to the B5.9 and L GAS PLUS CM556 engines, the C GAS PLUS CM556 model also integrates the humidity sensor to maintain optimal operating conditions. This engine’s design emphasizes reliability and performance, and the humidity sensor plays a key role in achieving these goals by providing essential data that helps in the prevention of moisture-related problems.

ISB5.9G CM2180 and ISL G CM2180

The ISB5.9G CM2180 and ISL G CM2180 engines are equipped with the humidity sensor to ensure that their high-performance capabilities are not compromised by environmental factors. These engines are known for their durability and efficiency, and the humidity sensor’s role in maintaining these qualities is indispensable. By providing real-time humidity data, the sensor helps in the early detection of potential issues, allowing for timely corrective actions.

ISX12 G CM2180 EJ

The ISX12 G CM2180 EJ engine also utilizes the humidity sensor to enhance its operational efficiency. This engine, designed for heavy-duty applications, benefits from the sensor’s ability to monitor and regulate humidity levels, ensuring that the engine operates at peak performance. The sensor’s integration into this model is critical for maintaining the engine’s reliability and longevity, especially in demanding environments.

Role of Part 4955125 Humidity Sensor in Engine Systems

The part 4955125 Humidity Sensor is an integral component in the orchestration of various engine systems, particularly in the realms of fuel management and engine control.

In the Fuel Control Module (FCM), the humidity sensor provides essential data regarding the ambient humidity levels. This information is vital for the FCM to adjust the fuel-air mixture accurately. Humidity affects air density, and thus, the sensor’s readings enable the FCM to make precise adjustments to the fuel delivery, ensuring optimal combustion efficiency and emissions control.

Within the Engine Control Module (ECM), the humidity sensor’s data is used to fine-tune various engine parameters. The ECM relies on this data to make real-time adjustments to ignition timing, fuel injection, and other critical functions. By accounting for humidity, the ECM can maintain engine performance under varying environmental conditions, enhancing both efficiency and reliability.

In the Module that integrates both fuel control and engine management functions, the humidity sensor plays a dual role. It ensures that the fuel control aspect of the module delivers the correct fuel mixture, while simultaneously providing the engine control aspect with the necessary data to optimize overall engine performance. This integrated approach allows for a more cohesive and responsive engine system, capable of adapting to changes in humidity with minimal delay.

Overall, the part 4955125 Humidity Sensor is a key player in maintaining the delicate balance required for efficient and effective engine operation across various modules and systems.

Conclusion

The Cummins 4955125 Humidity Sensor is a critical component in the efficient operation of commercial truck engines. By providing accurate humidity data, it enables the engine control unit to make real-time adjustments to fuel injection and air intake, leading to improved fuel efficiency, enhanced engine performance, and better maintenance practices. Its integration with various Cummins engines underscores its importance in maintaining engine efficiency and reliability under varying environmental conditions.

-

SAE International’s Dictionary of Testing, Verification and Validation, Jon M. Quigley, SAE International, 2023

↩ -

Modern Automotive Electrical Systems, Pedram Asef, Sanjeevikumar Padmanaban, and Andrew Lapthorn, Wiley, 2022

↩ -

Automotive Heating Ventilation and Air Conditioning, Quansheng Zhan, Shengbo Eben, Li Kun Deng, Jones Bartlett Learning, 2018

↩

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.