This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

Introduction

The Cummins 4970008 Wiring Harness is a specialized component designed for use in commercial trucks. It serves as a part of the vehicle’s electrical system, facilitating the connection between various electrical components and the truck’s power source. This wiring harness ensures that electrical signals and power are efficiently distributed throughout the truck, supporting the operation of systems and features.

Basic Concepts of Wiring Harnesses

A wiring harness is an assembly of wires, connectors, and sometimes switches and relays, which are bundled together to transmit electrical power and signals within a vehicle. The components of a wiring harness include individual wires, connectors, terminals, and protective coverings. These elements work together to ensure that electrical current is safely and efficiently routed to where it is needed. In a vehicle’s electrical system, the wiring harness plays a role by providing a structured and organized method for electrical distribution, reducing the risk of short circuits and improving the overall reliability of the electrical system 1.

Purpose of the 4970008 Wiring Harness

This Cummins part is specifically designed to integrate with the electrical systems of commercial trucks. It plays a role in connecting the truck’s engine control module (ECM) with various sensors, actuators, and other electrical components. This integration allows for the efficient management of engine performance, emissions control, and other functions. By providing a reliable pathway for electrical signals and power, the 4970008 Wiring Harness contributes to the overall operation and efficiency of the truck 2.

Key Features

The Cummins 4970008 Wiring Harness is characterized by its robust design and the use of high-quality materials. It is engineered to withstand the harsh conditions often encountered in commercial truck environments, including exposure to vibrations, temperature extremes, and moisture. The harness is constructed with durable wires and connectors that are resistant to corrosion and wear. Additionally, it may feature unique characteristics such as custom-molded connectors for a secure fit and enhanced protection against environmental factors 3.

Benefits

This part offers several advantages. It contributes to improved reliability by ensuring that electrical connections are secure and consistent. This reliability is important for the safe and efficient operation of commercial trucks. Additionally, the harness enhances efficiency by optimizing the distribution of electrical power and signals, which can lead to better fuel economy and reduced emissions. Safety is also improved, as the harness helps prevent electrical faults that could lead to malfunctions or accidents 4.

Installation Considerations

When installing the Cummins 4970008 Wiring Harness, it is important to follow guidelines and best practices to ensure proper integration with the truck’s electrical system. This may include verifying that all connections are secure and that the harness is routed away from moving parts and heat sources. Special tools or equipment may be required for installation, and it is advisable to consult the manufacturer’s instructions for specific recommendations.

Troubleshooting Common Issues

Common problems associated with wiring harnesses can include loose connections, damaged wires, or faulty connectors. Troubleshooting steps may involve inspecting the harness for visible signs of damage, testing electrical connections for continuity, and replacing any faulty components as necessary. Regular inspections and maintenance can help identify and address issues before they lead to more significant problems.

Maintenance Tips

To ensure the longevity and optimal performance of the Cummins 4970008 Wiring Harness, regular maintenance is recommended. This includes inspecting the harness for signs of wear or damage, ensuring that all connections are secure, and protecting the harness from environmental factors such as moisture and extreme temperatures. Following these maintenance tips can help prevent issues and ensure the reliable operation of the truck’s electrical system.

Cummins Overview

Cummins Inc. is a global power leader that designs, manufactures, and distributes engines, filtration, and power generation products. With a history dating back to 1919, Cummins has established itself as a trusted name in the commercial truck industry. The company is known for its commitment to innovation, quality, and customer satisfaction, providing solutions that meet the demanding requirements of commercial transportation.

ISM CM876 Engine and Wiring Harness 4970008

The Cummins ISM CM876 engine is a robust and reliable power unit widely used in various heavy-duty applications. The engine’s design emphasizes durability and efficiency, making it a preferred choice for many industries.

The Wiring Harness 4970008, manufactured by Cummins, is an essential component for the ISM CM876 engine. This wiring harness is integral to the engine’s electrical system, ensuring that all electrical components are properly connected and functioning. It plays a role in maintaining the engine’s performance and reliability by providing a secure and efficient pathway for electrical signals.

The harness is designed to withstand the harsh conditions typically encountered in heavy-duty environments. It is engineered to endure high temperatures, vibrations, and other stresses that are common in industrial settings. This ensures that the harness remains functional and reliable over the engine’s operational life.

The integration of the Wiring Harness 4970008 with the ISM CM876 engine is seamless, thanks to its precise design and high-quality materials. It connects various electrical components, including sensors, actuators, and control units, ensuring that the engine operates smoothly and efficiently. The harness is also designed to be easy to install and maintain, reducing downtime and enhancing the overall productivity of the engine.

Role of Part 4970008 Wiring Harness in Engine Systems

The part 4970008 wiring harness is integral to the efficient operation of various engine systems by providing a structured and reliable pathway for electrical signals and power. This harness connects multiple components, ensuring seamless communication and power distribution throughout the engine system.

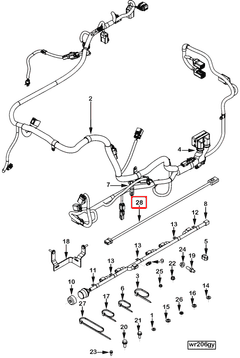

Integration with the Harness

The wiring harness serves as the backbone for the electrical system, linking the engine’s various sensors, actuators, and control modules. It routes power from the battery to essential components such as the fuel injectors, ignition coils, and various solenoids. Additionally, it facilitates the transmission of data from sensors like the mass airflow sensor, oxygen sensors, and throttle position sensor back to the electronic control module (ECM).

Connection to the Electronic Control Module (ECM) Wiring

A significant function of the part 4970008 wiring harness is its role in the ECM wiring. The ECM relies on accurate and timely data from numerous sensors to make precise adjustments to the engine’s operation. The wiring harness ensures that these signals are transmitted without interference or loss, allowing the ECM to optimize fuel delivery, ignition timing, and emissions control.

Moreover, the harness provides power to the ECM, enabling it to perform its computational tasks efficiently. It also connects the ECM to actuators such as the fuel injectors and idle air control valve, allowing the ECM to execute its commands effectively.

Conclusion

In summary, the part 4970008 wiring harness is a vital component that ensures the engine system operates harmoniously by providing a robust and organized framework for electrical connections. Its integration with the ISM CM876 engine enhances the engine’s performance, reliability, and efficiency, making it an essential part of the engine’s overall functionality.

-

Huang, M. (2002). Vehicle Crash Dynamics. CRC Press.

↩ -

Happian-Smith, J. (2002). An Introduction to Modern Vehicle Design. Butterworth-Heinemann.

↩ -

Reif, K. (2014). Diesel Engine Management Systems and Components. Springer.

↩ -

Stone, R. (2012). Introduction to Internal Combustion Engines, Fourth Edition. Macmillan.

↩

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.