4974922

BREATHER,CRANKCASE

Cummins®

IN STOCK

More than 10 are currently available

Ships within 1 business day

This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

The BREATHER, CRANKCASE (Part #4974922) manufactured by Cummins is a component designed to facilitate the ventilation of the crankcase in commercial trucks. It plays a role in the crankcase ventilation system by allowing for the release of pressure and the venting of gases that accumulate within the crankcase during engine operation.

Basic Concepts of Crankcase Ventilation

The crankcase ventilation system is designed to manage the buildup of gases and pressure within the crankcase of a truck engine. Its purpose is to ensure that the crankcase maintains a stable pressure environment, which is important for the efficient operation of the engine. The system functions by allowing gases produced during combustion, which escape past the piston rings into the crankcase, to be safely vented. Maintaining proper pressure within the crankcase helps prevent oil leaks, ensures adequate lubrication, and contributes to the overall efficiency and longevity of the engine 1.

Role and Function of the BREATHER, CRANKCASE

The BREATHER, CRANKCASE is integral to the operation of a truck’s engine. It allows for the controlled release of pressure and the venting of gases from the crankcase. By facilitating the escape of these gases, it helps maintain a stable pressure environment within the crankcase. This, in turn, supports the engine’s lubrication system by ensuring that oil is not forced out through seals and gaskets due to excessive pressure. Additionally, it plays a part in reducing the concentration of harmful gases within the crankcase, which can contribute to oil degradation and engine wear 2.

Key Features of the Cummins BREATHER, CRANKCASE

The Cummins BREATHER, CRANKCASE is engineered with specific design and construction features to ensure effective performance. It is constructed from durable materials that can withstand the harsh conditions within the engine compartment. The design includes filtration capabilities to prevent contaminants from entering the crankcase, which could lead to engine damage. Unique design elements may also be incorporated to enhance its efficiency and reliability in demanding applications 3.

Benefits of Using the Cummins BREATHER, CRANKCASE

Utilizing the Cummins BREATHER, CRANKCASE offers several advantages. It contributes to improved engine performance by ensuring that the crankcase maintains optimal pressure levels. This can lead to reduced wear on engine components, as stable pressure conditions help prevent oil from being forced out through seals and gaskets. Additionally, by venting harmful gases, it helps in preserving the quality of the engine oil, which is important for lubrication and cooling. The overall reliability of the engine is enhanced, as the system plays a part in preventing issues related to pressure buildup and contamination 4.

Installation and Maintenance

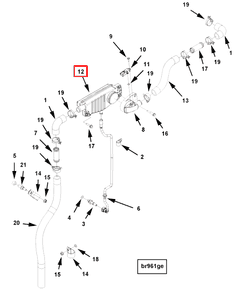

Proper installation of the Cummins BREATHER, CRANKCASE is important to ensure its effective operation. It should be securely fitted according to the manufacturer’s guidelines to prevent leaks and ensure proper ventilation. Routine maintenance checks are recommended to ensure the breather remains in good condition. This may include inspecting for signs of wear, ensuring the filtration system is clean and functional, and checking for any obstructions that could impede its operation. Regular maintenance helps in identifying potential issues early, ensuring the continued efficient operation of the crankcase ventilation system.

Troubleshooting Common Issues

Common problems associated with the BREATHER, CRANKCASE may include blockages, wear, or failure of the filtration system. Signs of these issues can manifest as oil leaks, increased engine noise, or decreased engine performance. Troubleshooting steps may involve inspecting the breather for physical damage, ensuring the filtration system is clean and operational, and checking for proper installation. If wear or failure is detected, replacement or repair may be necessary to restore the system’s functionality.

Cummins: A Brief Overview

Cummins Inc. is a global power leader that designs, manufactures, and distributes engines, filtration, and power generation products. With a history spanning over a century, Cummins has established a reputation for quality, innovation, and reliability in the commercial truck industry. The company’s commitment to excellence is reflected in its extensive product range, which includes engines, powertrains, and aftermarket parts designed to meet the demanding requirements of commercial applications. Cummins’ dedication to quality and innovation ensures that its products, including the BREATHER, CRANKCASE, are engineered to deliver reliable performance and durability in a variety of operating conditions.

Compatibility of Cummins Part 4974922: BREATHER, CRANKCASE

This Cummins part is compatible with various engine models, including the ISG12, ISX12, ISZ13, QSG12/X12, QSK19, QSZ13, X15, and Z13 series. Ensuring that this part is correctly installed and functioning is crucial for maintaining optimal performance and reliability across these engine models.

Understanding the Role of Part 4974922 BREATHER,CRANKCASE in Engine Systems

In the intricate arrangement of an engine system, this part plays a significant role in maintaining the engine’s efficiency and longevity. This component is designed to manage the pressure within the crankcase, a vital aspect of engine operation.

Integration with Engine Components

-

Crankcase Ventilation: The primary function of the crankcase breather is to allow the release of gases that accumulate within the crankcase. These gases, which include unburnt fuel, combustion byproducts, and moisture, are a natural byproduct of the engine’s operation. The breather ensures that these gases are expelled, preventing a buildup that could lead to increased pressure and potential damage to engine seals and components.

-

Oil Mist Separation: As the crankcase breather expels gases, it also encounters oil mist that is present due to the splashing of oil within the crankcase. This part is engineered to separate this oil mist from the expelled gases, ensuring that the oil is returned to the crankcase rather than being released into the atmosphere. This not only conserves oil but also reduces environmental contamination.

-

Pressure Equalization: By allowing the controlled release of gases, the crankcase breather helps in equalizing the pressure within the crankcase. This is essential for the proper functioning of the piston rings and other moving parts within the engine. Consistent pressure ensures that these components operate within their designed parameters, enhancing engine performance and reliability.

-

Connection to Air Intake System: In many engine designs, the crankcase breather is connected to the air intake system. This arrangement allows the expelled gases to be drawn into the intake manifold, where they are mixed with the incoming air-fuel mixture and combusted. This not only helps in reducing emissions but also ensures that any unburnt fuel is utilized, improving overall engine efficiency.

-

Maintenance of Clean Air-Fuel Mixture: By effectively managing the gases within the crankcase, the breather contributes to the maintenance of a clean air-fuel mixture. This is particularly important in turbocharged engines, where the increased pressure and temperature can exacerbate the accumulation of gases within the crankcase.

Conclusion

In summary, the BREATHER, CRANKCASE (Part #4974922) is a component that, while often overlooked, plays a vital role in the overall health and performance of an engine. Its proper function ensures that the crankcase remains a pressurized yet balanced environment, contributing to the engine’s efficiency, longevity, and environmental compliance.

-

Hu, Haoran, Simon J Baseley, and Xubin Song. Advanced Hybrid Powertrains for Commercial Vehicles Second Edition. SAE International, 2021.

↩ -

Lakshminarayanan, P. A., and Nagaraj S. Nayak. Critical Component Wear in Heavy Duty Engines. John Wiley & Sons, 2011.

↩ -

Reif, Konrad, ed. Fundamentals of Automotive and Engine Technology: Standard Drives, Hybrid Drives, Brakes, Safety Systems. Springer Vieweg, 2014.

↩ -

Randall, Martynn. Haynes Manual on Diesel Engines. Haynes Publishing, 2015.

↩

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.