This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

The Cummins 4981015 Compressor Water Inlet Tube is a component designed for use in heavy-duty trucks. Its purpose is to facilitate the efficient operation of the engine cooling system by directing water into the compressor. This part plays a role in maintaining the optimal temperature of the engine, thereby contributing to the overall performance and reliability of the truck 1.

Basic Concepts of Compressor Water Inlet Tubes

A compressor water inlet tube is a part of the engine cooling system that allows water to enter the compressor. This tube interacts with the water pump, radiator, and other cooling system components to ensure that the engine remains at an optimal operating temperature. The tube’s design and placement are important for the effective circulation of coolant, which helps in dissipating heat generated by the engine 2.

Purpose and Role in Truck Operation

The Cummins 4981015 Compressor Water Inlet Tube is specifically designed to enhance the efficiency of the engine cooling system in heavy-duty trucks. By ensuring a steady flow of coolant into the compressor, it helps in maintaining the engine’s temperature within safe limits. This contributes to the engine’s performance and longevity, as well as the truck’s overall reliability. The tube’s role is particularly important in high-stress environments where the engine is subjected to prolonged operation and heavy loads 3.

Key Features

The Cummins 4981015 Compressor Water Inlet Tube is characterized by several key features that enhance its performance and durability. These include a robust design that can withstand high pressure and temperature, the use of high-quality materials resistant to corrosion and wear, and precise engineering to ensure a secure fit and efficient coolant flow. These features collectively contribute to the tube’s reliability and effectiveness in demanding applications 4.

Benefits

Using the Cummins 4981015 Compressor Water Inlet Tube offers several benefits. It contributes to improved engine cooling efficiency, which can lead to better engine performance and longevity. The tube’s durable construction and resistance to corrosion also mean that it requires less frequent replacement, potentially leading to cost savings over time. Additionally, its precise engineering ensures a secure and effective fit, reducing the risk of leaks and other issues.

Installation Process

Installing the Cummins 4981015 Compressor Water Inlet Tube requires careful attention to detail to ensure a secure and effective fit. Preparatory steps include cleaning the installation area and inspecting the tube for any damage. The necessary tools may include wrenches, sealant, and possibly a torque wrench. Following the manufacturer’s instructions for torque specifications and sealant application is important to ensure the tube is properly installed. Best practices include double-checking all connections and performing a pressure test to confirm there are no leaks.

Troubleshooting Common Issues

Common issues with the Cummins 4981015 Compressor Water Inlet Tube may include leaks, blockages, or corrosion. Leaks can often be traced to improper installation or damage to the tube. Blockages may result from debris in the cooling system, while corrosion can be a sign of material degradation or incompatible coolant use. Troubleshooting these issues involves inspecting the tube and connections, cleaning or replacing parts as necessary, and ensuring the cooling system is free of contaminants.

Maintenance Tips

Regular maintenance of the Cummins 4981015 Compressor Water Inlet Tube is important for ensuring its longevity and optimal performance. This includes periodic inspections for signs of wear, corrosion, or leaks. Maintaining the cooling system with the recommended type and concentration of coolant is also important. Following a scheduled maintenance plan that includes checks and possible replacements of the tube can help prevent unexpected failures and ensure the engine cooling system operates efficiently.

About Cummins

Cummins Inc. is a global power leader that designs, manufactures, and distributes a wide range of power solutions, including engines, filtration, and emission solutions. With a history of innovation and quality, Cummins is known for its commitment to customer satisfaction and has established a strong reputation in the automotive industry. The company’s product offerings are designed to meet the demanding requirements of various applications, from heavy-duty trucks to industrial equipment.

Cummins Compressor Water Inlet Tube 4981015 Compatibility

The Cummins Compressor Water Inlet Tube part number 4981015 is designed to fit seamlessly with several engine models, ensuring optimal performance and reliability. This part is integral to the cooling system of these engines, facilitating the flow of water to the compressor.

ISL9 Engines

The ISL9 engine series, known for its robust performance and efficiency, incorporates the 4981015 Compressor Water Inlet Tube. This part is essential for maintaining the correct water flow to the compressor, which helps in regulating the engine’s temperature and ensuring smooth operation.

CM2150 Engines

The CM2150 engine series, another high-performance lineup from Cummins, also utilizes the 4981015 Compressor Water Inlet Tube. This component is crucial for the cooling system, ensuring that the compressor receives the necessary water flow to maintain optimal operating conditions.

SN Engines

The SN engine series, recognized for its versatility and durability, is another beneficiary of the 4981015 Compressor Water Inlet Tube. This part is designed to fit perfectly within the SN engine’s cooling system, ensuring efficient water flow to the compressor and contributing to the engine’s overall performance and longevity.

Role of Part 4981015 Compressor Water Inlet Tube in Engine Systems

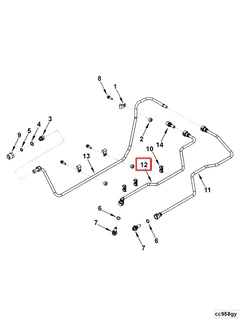

The part 4981015 Compressor Water Inlet Tube is an essential component in the arrangement of engine systems, particularly in the management and regulation of the compressor coolant. This tube facilitates the precise delivery of coolant into the compressor, ensuring optimal thermal management.

In the context of the compressor coolant system, the 4981015 tube is positioned to direct coolant flow from the engine’s cooling circuit to the compressor. This is achieved through a well-engineered pathway that minimizes resistance and ensures a consistent flow rate. The tube interfaces with the compressor’s inlet port, allowing coolant to enter the compressor housing.

The arrangement of this tube within the engine system is designed to maintain the compressor’s operational temperature within specified limits. By efficiently channeling coolant, the tube helps in dissipating heat generated during compression cycles, thereby enhancing the compressor’s performance and longevity.

Furthermore, the integration of the 4981015 tube into the engine’s coolant system ensures that the compressor operates under stable thermal conditions. This stability is vital for the consistent performance of the compressor, as fluctuations in temperature can lead to inefficiencies and potential damage.

In summary, the 4981015 Compressor Water Inlet Tube plays a significant role in the effective management of compressor coolant, contributing to the overall efficiency and reliability of engine systems.

Conclusion

The Cummins 4981015 Compressor Water Inlet Tube is a critical component in the engine cooling system of heavy-duty trucks. Its role in maintaining optimal engine temperature, coupled with its durable construction and efficient design, makes it an essential part for ensuring the performance and reliability of the vehicle. Regular maintenance and proper installation are key to maximizing the benefits of this Cummins part.

-

Composite Materials Handbook Volume 4 Metal Matrix Composites, SAE International, 2013

↩ -

Automotive Fuels Reference Book, Paul Richards and Jim Barker, SAE International, 2023

↩ -

Automotive Lubricants Reference Book, Arthur J Caines, Roger F Haycock and John E Hillier, SAE International, 2004

↩ -

Vehicle Dynamics: Theory and Application, Reza N. Jazar, Springer, 2017

↩

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.