4983620

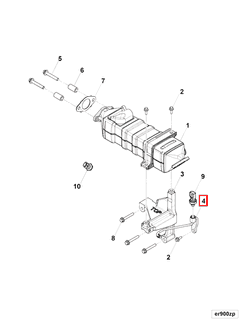

Pressure Sensing Tube

Cummins®

IN STOCK

More than 10 are currently available

Ships within 1 business day

This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

Introduction

The Cummins 4983620 Pressure Sensing Tube is a component designed for use in commercial trucks. Its purpose is to facilitate the accurate measurement and monitoring of pressure within the truck’s systems. This part plays a role in ensuring that the truck operates efficiently and safely by providing precise pressure readings to the vehicle’s control systems.

Basic Concepts of Pressure Sensing Tubes

A pressure sensing tube is a conduit that allows for the transmission of pressure from a specific point within a system to a pressure sensor or gauge. It functions by maintaining a direct pathway for pressure to travel, ensuring that the sensor receives an accurate representation of the pressure at the source. The importance of these tubes lies in their ability to monitor and regulate pressure, which is vital for the proper functioning of various systems within a vehicle 1.

Role of the 4983620 Pressure Sensing Tube in Truck Operation

The Cummins 4983620 Pressure Sensing Tube is integrated into the truck’s pressure monitoring system. It connects to pressure sensors and other components, allowing for the accurate measurement of pressure in critical areas such as the fuel system, brake system, or engine compartments. This tube enables the truck’s electronic control unit (ECU) to receive real-time data, which it uses to make adjustments for optimal performance and safety.

Key Features

The Cummins 4983620 Pressure Sensing Tube is characterized by its robust design and the materials used in its construction. It is made from high-quality materials that offer resistance to corrosion and wear, ensuring durability in the demanding environment of a commercial truck. The tube’s design includes features that enhance its performance, such as precise fittings for secure connections and a smooth interior to facilitate the flow of pressure without loss.

Benefits

The use of the Cummins 4983620 Pressure Sensing Tube offers several benefits. It provides improved accuracy in pressure readings, which is crucial for the precise operation of the truck’s systems. Its enhanced durability ensures long-term reliability, reducing the need for frequent replacements. Additionally, the tube contributes to overall system efficiency by enabling the ECU to make informed adjustments based on accurate pressure data.

Troubleshooting and Maintenance

To ensure the optimal performance and longevity of the Cummins 4983620 Pressure Sensing Tube, regular maintenance and troubleshooting are recommended. This includes checking for signs of wear or damage, ensuring all connections are secure, and verifying that the tube is free from obstructions. In the event of inaccurate pressure readings, inspecting the tube and its connections can help identify and resolve issues.

About Cummins

Cummins Inc. is a global power leader that designs, manufactures, and distributes a wide range of power solutions. With a history spanning over a century, Cummins has established itself as an expert in the manufacturing of automotive components, including engines, filtration, and emissions solutions. The company is committed to quality and innovation, continually advancing its products to meet the evolving needs of the transportation industry.

Compatibility with Cummins Engines

The Pressure Sensing Tube, part number 4983620, manufactured by Cummins, is a critical component in various Cummins engine models. This part is integral to the engine’s operation, ensuring accurate pressure readings which are essential for maintaining optimal engine performance and efficiency.

B6.7 Series

The B6.7 series engines, including the B6.7 CM2350 B135B, ISB6.7 CM2250, ISB6.7 CM2350 B101, QSB6.7 CM2250, and QSB6.7 CM2350 B105, are designed for heavy-duty applications and are known for their robust performance and reliability. The Pressure Sensing Tube in these engines is specifically engineered to withstand the high pressures and demanding conditions typical of these models. It ensures precise measurement of pressure parameters, contributing to the engine’s overall efficiency and longevity.

ISB Series

The ISB engines, such as the ISB (Chrysler) and ISB6.7 CM2250, are another category where the Pressure Sensing Tube is utilized. These engines are often found in commercial and industrial applications, where they are required to deliver consistent power and reliability. The Pressure Sensing Tube in these engines plays a crucial role in monitoring and regulating pressure levels, ensuring that the engine operates within safe parameters.

QSB Series

The QSB series engines, including the QSB6.7 CM2250 and QSB6.7 CM2350 B105, are designed for a variety of applications, from agricultural to construction. The Pressure Sensing Tube in these engines is designed to provide accurate pressure readings, which are essential for maintaining the engine’s performance and efficiency. This part is engineered to meet the specific needs of these engines, ensuring reliable operation in diverse environments.

Grouping by Application

While the Pressure Sensing Tube is used across various Cummins engine models, it is particularly important in engines designed for heavy-duty and industrial applications. These engines, including the B6.7, ISB, and QSB series, benefit from the precise pressure measurements provided by this component, ensuring optimal performance and durability.

Role of Part 4983620 Pressure Sensing Tube in Engine Systems

The Part 4983620 Pressure Sensing Tube is an integral component in the operation of various engine systems, particularly in the management of recirculation and exhaust processes.

In the context of Exhaust Gas Recirculation (EGR) systems, the Pressure Sensing Tube monitors the pressure differentials between the intake and exhaust manifolds. This data is vital for the EGR valve to function correctly, ensuring that the appropriate amount of exhaust gas is recirculated back into the intake manifold. This recirculation helps in reducing nitrogen oxides (NOx) emissions, contributing to a cleaner combustion process 2.

For Exhaust systems, the Pressure Sensing Tube plays a significant role in maintaining the efficiency of the exhaust gas flow. By continuously monitoring the pressure within the exhaust manifold, it provides essential feedback to the engine control unit (ECU). This allows the ECU to make real-time adjustments to the fuel injection and ignition timing, optimizing engine performance and fuel efficiency.

Additionally, the Pressure Sensing Tube aids in the detection of any irregularities within the exhaust system, such as blockages or leaks. Early detection of such issues allows for timely maintenance, preventing potential damage to the engine and ensuring prolonged system reliability.

Conclusion

In summary, the Part 4983620 Pressure Sensing Tube is a key component in enhancing the performance and efficiency of engine systems through precise pressure monitoring and feedback. Its robust design and compatibility with various Cummins engine models make it an essential part for maintaining optimal engine operation and reliability.

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.