This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

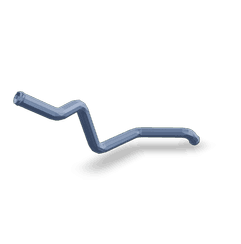

The Compressor Air Inlet Tube, part number 4988872, manufactured by Cummins, is a critical component in the air intake system of specific engine models. This part is designed to fit seamlessly with the ISB CM2150 and ISB6.7 CM2250 engines. Its primary function is to direct and manage the flow of air into the engine’s compressor, ensuring optimal performance and efficiency.

Functionality within the Compressor Air Inlet Arrangement

In the Compressor Air Inlet Arrangement, the Compressor Air Inlet Tube serves as a conduit for air entering the compressor. Its primary function is to direct ambient air from the surroundings into the compressor with minimal turbulence and pressure loss. This ensures that the compressor receives a steady and consistent airflow, which is vital for maintaining optimal compression ratios and engine performance 1.

Interaction with Other Components

-

Compressor Section: The air directed by the Compressor Air Inlet Tube is crucial for the operation of the compressor blades. Efficient airflow ensures that the compressor can effectively increase the pressure of the incoming air, which is a fundamental aspect of the engine’s compression cycle 2.

-

Engine Performance: The consistent airflow provided by the Compressor Air Inlet Tube contributes to stable engine performance. It helps in maintaining the desired air-fuel ratio, which is essential for combustion efficiency and overall engine output 3.

-

Thermal Management: Proper airflow facilitated by the Compressor Air Inlet Tube also plays a role in thermal management. It helps in cooling critical components within the compressor and the engine, preventing overheating and ensuring longevity of the engine parts.

-

Noise Reduction: The design of the Compressor Air Inlet Tube is also aimed at reducing noise levels. By smoothing the airflow and minimizing turbulence, it contributes to a quieter operation of the engine, which is particularly important in applications where noise reduction is a priority.

Key Features

This Cummins part is constructed with a focus on durability and efficiency. It is made from high-quality materials that are resistant to wear and corrosion, ensuring a long service life even under demanding conditions. The design of the tube includes features that enhance its functionality, such as a smooth interior to reduce air turbulence and improve flow efficiency. Additionally, the tube is engineered to withstand the high pressures and temperatures associated with compressor operations, making it a reliable component in the truck’s air system.

Benefits

The use of the Compressor Air Inlet Tube offers several advantages. It contributes to improved air flow efficiency, which can lead to better compressor performance and overall system reliability. The tube’s design also helps in reducing noise levels associated with air intake, contributing to a quieter operating environment. Furthermore, its durable construction ensures that it can withstand the rigors of commercial truck operations, providing long-term value and reliability.

Installation and Compatibility

Proper installation of the Compressor Air Inlet Tube is important for ensuring optimal performance and compatibility with the truck’s air system. Installation guidelines should be followed to ensure that the tube is securely fitted and aligned correctly with the compressor and other components. Specific requirements or considerations may vary depending on the truck model, and it is important to consult the manufacturer’s instructions or a professional technician to ensure correct installation.

Maintenance and Troubleshooting

Regular maintenance of the Compressor Air Inlet Tube is important for preserving its performance and longevity. This includes periodic inspections for signs of wear, corrosion, or damage. Cleaning the tube to remove any debris or contaminants that could obstruct air flow is also recommended. In the event of common issues such as reduced air flow or unusual noises, troubleshooting steps may involve checking for blockages, ensuring proper alignment, or inspecting for damage that may require repair or replacement.

Performance Impact

The Compressor Air Inlet Tube can have a noticeable impact on the overall performance of the truck’s air system. By ensuring a consistent and efficient air supply to the compressor, the tube contributes to improved compressor efficiency and system reliability. This can lead to enhanced performance of air-dependent systems, such as brakes and suspensions, and may also contribute to overall fuel efficiency by supporting optimal compressor operation.

Safety Considerations

When installing or maintaining the Compressor Air Inlet Tube, it is important to observe safety precautions. This includes using proper handling procedures to avoid injury from sharp edges or high-pressure air. Safety equipment, such as gloves and eye protection, should be worn during installation and maintenance tasks. Additionally, ensuring that the tube is correctly installed and maintained can help prevent accidents related to air system failures.

Environmental Impact

The use of the Compressor Air Inlet Tube can have environmental implications, particularly in terms of emissions and fuel efficiency. By contributing to efficient compressor operation, the tube may help in reducing unnecessary fuel consumption and emissions. Cummins is committed to developing products that not only enhance performance but also consider environmental impact, aiming to provide solutions that balance efficiency with ecological responsibility.

Conclusion

The Compressor Air Inlet Tube, part number 4988872, is a vital component in the air intake system of specific engine models. Its role in ensuring efficient airflow to the compressor contributes to the overall performance and reliability of the engine system. Proper installation, regular maintenance, and adherence to safety precautions are essential for maximizing the benefits of this part.

-

Mananathan, R. (2022). Automobile Wheel Alignment and Wheel Balancing. SAE International.

↩ -

Watson, B. (2011). Mobile Equipment Hydraulics A Systems and Troubleshooting Approach. Cengage Learning.

↩ -

Bartz, W. J. (2019). Engine Oils and Automotive Lubrication Mechanical Engineering Book 80. CRC Press.

↩

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.