This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

Introduction

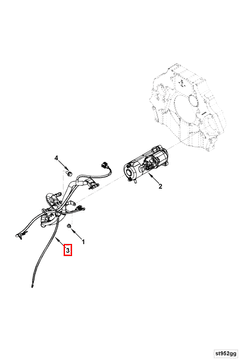

The Cummins 4990138 Wiring Harness is a specialized component designed for use in commercial trucks. It serves as a vital part of the vehicle’s electrical system, facilitating the connection between various electrical components and the truck’s power source. This wiring harness is integral to ensuring the reliable operation of the truck’s electrical systems, contributing to overall vehicle performance and safety.

Basic Concepts of Wiring Harnesses

A wiring harness is an assembly of wires, connectors, and sometimes switches that transmit electrical power and signals between different components of a vehicle. It is designed to organize and protect the wires, reducing the risk of damage and ensuring efficient signal transmission. Within a vehicle’s electrical system, the wiring harness plays a role by providing a structured pathway for electricity to flow from the power source to the components that require it, such as lights, sensors, and control units 1.

Purpose of the 4990138 Wiring Harness

The Cummins 4990138 Wiring Harness is specifically designed to integrate with the electrical systems of commercial trucks. It connects various electrical components, allowing them to communicate and function together. This harness plays a role in the operation of the truck by ensuring that all electrical systems receive the necessary power and signals to operate correctly. Its design allows for seamless integration with other systems and components, enhancing the truck’s overall functionality 2.

Key Features

The Cummins 4990138 Wiring Harness is characterized by its robust design and the high-quality materials used in its construction. It features a durable insulation that protects the wires from environmental factors and physical damage. The harness is also designed with precision to fit snugly within the truck’s chassis, ensuring that it does not interfere with other components. Additionally, it includes connectors that are resistant to corrosion and wear, enhancing the harness’s performance and longevity 3.

Benefits of Using the 4990138 Wiring Harness

Utilizing the Cummins 4990138 Wiring Harness in commercial trucks offers several advantages. It contributes to improved efficiency by ensuring that electrical signals are transmitted quickly and accurately. The harness’s reliable design enhances the truck’s operational safety by reducing the risk of electrical failures. Furthermore, its durability ensures that it can withstand the demanding conditions of commercial truck operations, providing long-term value to fleet operators 4.

Installation Considerations

When installing the Cummins 4990138 Wiring Harness, it is important to follow guidelines and best practices to ensure proper integration with the truck’s electrical system. Preparatory steps may include disconnecting the battery to prevent electrical shocks and ensuring that the truck’s chassis is clean and free of debris. The use of appropriate tools, such as wire strippers and crimping tools, is recommended to facilitate a secure and efficient installation process 5.

Maintenance and Troubleshooting

To ensure the longevity and optimal performance of the Cummins 4990138 Wiring Harness, regular maintenance is advised. This includes inspecting the harness for signs of wear or damage, ensuring that all connections are secure, and cleaning the harness to remove any dirt or debris. Common issues that may arise include corroded connectors or damaged wires, which can be addressed by repairing or replacing the affected parts. Regular checks and timely interventions can help prevent more significant problems down the line 6.

Safety Precautions

When working with the Cummins 4990138 Wiring Harness, observing important safety measures is crucial. Electrical safety practices, such as disconnecting the battery before beginning work, should be followed to prevent electrical shocks. Additionally, handling the harness with care, avoiding sharp edges or excessive force, can help prevent damage to the wires and connectors. Adhering to these safety precautions ensures a safe working environment and protects the integrity of the electrical system 7.

Cummins Overview

Cummins Inc. is a global power leader that designs, manufactures, and distributes engines, filtration, and power generation products. With a history spanning over a century, Cummins has established itself as a trusted name in the commercial truck industry. The company is committed to quality and innovation, continuously striving to improve its products and services to meet the evolving needs of its customers. Cummins’ dedication to excellence is evident in its wide range of components, including the 4990138 Wiring Harness, which is designed to enhance the performance and reliability of commercial trucks 8.

Conclusion

The Cummins 4990138 Wiring Harness is a critical component in the electrical system of commercial trucks, ensuring the reliable operation of various electrical components. Its robust design, high-quality materials, and precise engineering contribute to the overall performance and safety of the vehicle. Regular maintenance and adherence to safety precautions are essential for the longevity and optimal performance of this Cummins part.

-

Lakshminarayanan, P. A., & Kumar, A. (2020). Design and Development of Heavy Duty Diesel Engines: A Handbook. Springer Nature.

↩ -

Heywood, J. (2019). Internal Combustion Engine Fundamentals. McGraw-Hill Education.

↩ -

Arora, S., Abkenar, A. T., & Jayasi, S. G. (2021). Heavyduty Electric Vehicles: From Concept to Reality. Elsevier.

↩ -

Cummins Inc. (n.d.). QSL9 CM2250 Service Manual (4022256).

↩ -

Cummins Inc. (n.d.). QSL9 CM2250 Service Manual (4022256).

↩ -

Cummins Inc. (n.d.). QSL9 CM2250 Service Manual (4022256).

↩ -

Cummins Inc. (n.d.). QSL9 CM2250 Service Manual (4022256).

↩ -

Cummins Inc. (n.d.). QSL9 CM2250 Service Manual (4022256).

↩

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.