4991240

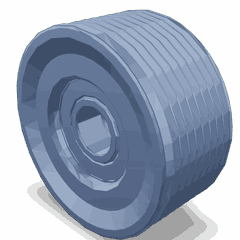

Idler Pulley

Cummins®

IN STOCK

More than 10 are currently available

Ships within 1 business day

This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

Cummins Part #4991240 Idler Pulley: A Comprehensive Guide

What is an Idler Pulley?

An idler pulley is a critical component in a vehicle’s engine system, primarily responsible for maintaining the tension in the serpentine belt. This ensures that all ancillary components, such as the alternator, power steering pump, and air conditioning compressor, operate efficiently. By redirecting the belt’s path, the idler pulley allows it to drive multiple pulleys simultaneously, which is crucial for maintaining proper tension and alignment. This alignment is essential for the efficient operation of the engine’s accessories 3.

Historical Context and Development

The use of idler pulleys dates back to the early days of automotive engineering. Initially, simpler designs were employed, but advancements in materials and engineering have led to more efficient and durable designs. Cummins, a leading manufacturer in the heavy-duty truck industry, has been at the forefront of developing high-quality idler pulleys. Their innovations have significantly improved the reliability and performance of commercial truck engines 1.

Types of Alternator Mountings

Alternator mountings can vary, including fixed, adjustable, and tensioner-based systems. Each type has its own advantages and is suited to different engine configurations. Understanding the type of alternator mounting in a specific engine is crucial for selecting the appropriate idler pulley. Cummins idler pulleys are designed to work seamlessly with various mounting systems, ensuring optimal performance 3.

Function and Importance

This part plays a critical role in maintaining the tension of the serpentine belt, which drives essential components such as the alternator, water pump, and air conditioning compressor. A properly functioning idler pulley ensures that these components operate at peak efficiency, reducing wear and tear on the engine and improving overall performance 3.

Quality and Durability

Cummins idler pulleys are manufactured using high-quality materials that withstand the rigors of heavy-duty use. The use of durable metals and advanced coatings enhances longevity and performance. Cummins is renowned for its stringent quality control processes, ensuring that each idler pulley meets the highest standards of performance and reliability 1.

Indicators for Replacement

Common indicators of a failing idler pulley include squealing or chirping noises, visible wear on the pulley, and a loose or slipping belt. These symptoms can lead to more severe engine issues if not addressed promptly. Replacing a worn idler pulley is crucial to prevent damage to other engine components and ensure the continued efficiency of the engine’s accessories 3.

Maintenance Tips

Mechanics and fleet operators should regularly inspect the idler pulley for signs of wear, damage, or misalignment. This proactive approach can prevent unexpected breakdowns. Ensuring that the idler pulley is properly lubricated can reduce friction and extend its lifespan. Cummins recommends using the appropriate lubricants specified in the engine’s maintenance manual. When replacing an idler pulley, it is essential to follow the manufacturer’s guidelines for proper installation. Incorrect installation can lead to premature failure and reduced performance 2.

This guide provides a comprehensive understanding of the Cummins part #4991240 idler pulley, its function, importance, and maintenance. It is designed to educate engineers, mechanics, truck drivers, and fleet operators, ensuring they have the knowledge needed to maintain and troubleshoot this critical engine component effectively.

Compatibility of Idler Pulley Part 4991240 with Cummins Engines

The Idler Pulley part 4991240, manufactured by Cummins, is a crucial component in the engine’s belt-driven system. It ensures the proper tension and alignment of the serpentine belt, which in turn drives essential engine accessories such as the alternator, water pump, and air conditioning compressor. This part is designed to fit a wide range of Cummins engines, ensuring compatibility across various models and configurations.

Compatible Engines

-

4B3.9

- The 4B3.9 engine benefits from the 4991240 Idler Pulley, ensuring smooth operation and longevity of the belt system.

-

6B5.9

- This engine model is also compatible with the 4991240 Idler Pulley, providing reliable performance and maintaining the integrity of the belt-driven accessories.

-

6C8.3

- The 6C8.3 engine utilizes the 4991240 Idler Pulley to ensure efficient power transfer and reduce wear on the belt and driven components.

-

B4.5

- The B4.5 engine is designed to work seamlessly with the 4991240 Idler Pulley, enhancing the overall efficiency and durability of the engine’s belt system.

-

B4.5 CM2350 B129B

- This variant of the B4.5 engine is also compatible with the 4991240 Idler Pulley, ensuring precise belt tension and alignment.

-

B5.9 G

- The B5.9 G engine is another model that fits the 4991240 Idler Pulley, providing consistent performance and reducing the risk of belt slippage.

-

B5.9 GAS PLUS CM556

- This engine model benefits from the 4991240 Idler Pulley, maintaining optimal belt tension and accessory operation.

-

B6.7 CM2350 B135B

- The B6.7 CM2350 B135B engine is compatible with the 4991240 Idler Pulley, ensuring reliable power transfer and accessory function.

-

B6.7 CM2670 B153B

- This engine model also fits the 4991240 Idler Pulley, providing consistent belt tension and reducing wear on the belt and driven components.

-

B6.7 G CMOH6.0 B125

- The B6.7 G CMOH6.0 B125 engine is designed to work with the 4991240 Idler Pulley, ensuring smooth operation and longevity of the belt system.

-

C GAS PLUS CM556

- The C GAS PLUS CM556 engine is compatible with the 4991240 Idler Pulley, providing reliable performance and maintaining the integrity of the belt-driven accessories.

-

C8.3 G

- The C8.3 G engine utilizes the 4991240 Idler Pulley to ensure efficient power transfer and reduce wear on the belt and driven components.

-

F3.8 CM2350 F120B

- The F3.8 CM2350 F120B engine is designed to work seamlessly with the 4991240 Idler Pulley, enhancing the overall efficiency and durability of the engine’s belt system.

-

F3.8 CM2620 F137B

- This engine model is also compatible with the 4991240 Idler Pulley, ensuring precise belt tension and alignment.

-

F4.5 CM2620 F139B

- The F4.5 CM2620 F139B engine benefits from the 4991240 Idler Pulley, ensuring smooth operation and longevity of the belt system.

-

G8.3

- The G8.3 engine is compatible with the 4991240 Idler Pulley, providing consistent performance and reducing the risk of belt slippage.

-

ISB CM2150

- The ISB CM2150 engine is designed to work with the 4991240 Idler Pulley, ensuring reliable power transfer and accessory function.

-

ISB CM550

- This engine model also fits the 4991240 Idler Pulley, providing consistent belt tension and reducing wear on the belt and driven components.

-

ISB CM850

- The ISB CM850 engine is compatible with the 4991240 Idler Pulley, ensuring smooth operation and longevity of the belt system.

-

ISB/ISD4.5 CM2150 B119

- The ISB/ISD4.5 CM2150 B119 engine benefits from the 4991240 Idler Pulley, ensuring precise belt tension and alignment.

-

ISB/ISD6.7 CM2150 SN

- This engine model is also compatible with the 4991240 Idler Pulley, ensuring reliable performance and maintaining the integrity of the belt-driven accessories.

-

ISB4.5 CM2350 B104

- The ISB4.5 CM2350 B104 engine is designed to work seamlessly with the 4991240 Idler Pulley, enhancing the overall efficiency and durability of the engine’s belt system.

-

ISB5.9G CM2180

- The ISB5.9G CM2180 engine is compatible with the 4991240 Idler Pulley, providing consistent performance and reducing the risk of belt slippage.

-

ISB6.7 CM2250

- This engine model also fits the 4991240 Idler Pulley, providing consistent belt tension and reducing wear on the belt and driven components.

-

ISB6.7 CM2350 B101

- The ISB6.7 CM2350 B101 engine benefits from the 4991240 Idler Pulley, ensuring smooth operation and longevity of the belt system.

By ensuring compatibility with these Cummins engines, the 4991240 Idler Pulley provides a reliable and efficient solution for maintaining the integrity of the belt-driven system, ultimately contributing to the overall performance and longevity of the engine.

Role of Part 4991240 Idler Pulley in Engine Systems

The Part 4991240 Idler Pulley is an integral component in the orchestration of various engine systems, ensuring the smooth operation and efficiency of the engine’s accessory support mechanisms.

Alternator Drive System

In the context of the alternator drive system, the Idler Pulley assists in maintaining the proper tension of the drive belt. This ensures that the alternator, which is responsible for generating electrical power to charge the battery and power the electrical systems of the vehicle, operates efficiently without slippage or excessive wear.

Alternator Mounting

When considering the alternator mounting and its interaction with the Idler Pulley, it’s important to note that the pulley helps in distributing the load across the belt, reducing stress on the alternator mounting points. This contributes to the longevity of the alternator and its mounting components.

Compressor and Refrigerant Connections

In systems involving the compressor and refrigerant connections, the Idler Pulley plays a role in the drive mechanism for the compressor. By maintaining belt tension, it ensures that the compressor operates smoothly, which is essential for the efficient circulation of refrigerant and the overall performance of the air conditioning system.

Water Inlet and Water Pump Drive

The water inlet and water pump drive are also influenced by the Idler Pulley. It ensures that the drive belt connecting to the water pump maintains optimal tension. This is vital for the pump’s ability to circulate coolant through the engine, preventing overheating and ensuring consistent engine temperature.

Fan-Driven Systems

In fan-driven systems, the Idler Pulley is responsible for keeping the belt taut as it drives the fan. This is essential for effective airflow across the radiator and other heat exchangers, contributing to the engine’s cooling efficiency.

Idler Pulley Kit and Support

The idler pulley kit and idler pulley support are specifically designed components that work in conjunction with the Idler Pulley to provide a stable and adjustable platform for the pulley. This setup allows for precise tensioning of the drive belt, accommodating various engine configurations and accessory layouts.

Location and Mounting

Lastly, the location of the Idler Pulley within the engine compartment is strategically chosen to offer the best possible belt routing and tensioning capabilities. Its mounting points are designed to withstand the dynamic forces exerted by the rotating belt, ensuring reliable operation under all driving conditions 3.

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.