This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

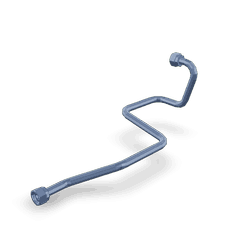

The Compressor Water Outlet Tube, part number 4994815, is a component manufactured by Cummins, a prominent name in the automotive and heavy-duty truck industries. This part is integral to the operation of heavy-duty trucks, contributing to the efficient management of engine temperatures through its role in the cooling system.

Function and Operation

The Compressor Water Outlet Tube facilitates the flow of coolant from the compressor to other parts of the engine. It is designed to ensure that the coolant is distributed effectively, which helps in maintaining the optimal operating temperature of the engine. This tube is a conduit that plays a role in the engine cooling system by allowing coolant to exit the compressor and travel to areas where it is needed to absorb and dissipate heat 1.

Purpose of the Compressor Water Outlet Tube

The specific role of the Compressor Water Outlet Tube is to maintain optimal engine temperature and ensure the efficient operation of the truck’s compressor. By providing a pathway for coolant to exit the compressor, it helps prevent overheating, which can lead to engine damage and reduced performance. This part is designed to work in conjunction with other components of the cooling system to maintain a stable engine temperature under various operating conditions 2.

Key Features

The Compressor Water Outlet Tube is constructed with materials that are resistant to corrosion and high temperatures, ensuring durability and long-term performance. It features secure connection types that are designed to withstand the pressures and temperatures of the cooling system. The design of this tube includes features that enhance its performance, such as smooth internal surfaces to facilitate coolant flow and robust construction to endure the rigors of heavy-duty truck operation 3.

Benefits

The advantages provided by the Compressor Water Outlet Tube include improved coolant flow, which contributes to enhanced engine protection. Its design and construction help increase the reliability of the cooling system, particularly in demanding operating conditions. The efficient distribution of coolant helps to maintain engine efficiency and longevity 4.

Installation Considerations

When installing the Compressor Water Outlet Tube, it is important to follow guidelines and best practices to ensure optimal performance and longevity. This includes adhering to proper torque specifications for connections, using appropriate sealing methods to prevent leaks, and ensuring correct alignment during installation. These practices help to maintain the integrity of the cooling system and the effectiveness of the tube 5.

Troubleshooting and Maintenance

Common issues associated with the Compressor Water Outlet Tube may include leaks, blockages, or damage from corrosion. Diagnostic procedures for identifying problems can involve visual inspections, pressure tests, and monitoring the engine’s temperature during operation. Recommended maintenance practices to prevent failures and extend service life include regular inspections, cleaning, and replacing the tube if signs of wear or damage are detected 6.

Cummins Overview

Cummins Inc. is a global power leader that designs, manufactures, and distributes a wide range of power solutions, including engines, filtration, and emissions solutions. With a history of innovation and a strong reputation in the automotive and heavy-duty truck industries, Cummins is known for its commitment to quality and reliability. The Compressor Water Outlet Tube is part of Cummins’ extensive product line, reflecting the company’s dedication to providing high-quality components for the transportation sector.

Compatibility

The Compressor Water Outlet Tube part number 4994815 is designed to fit seamlessly within a range of Cummins engine models. This part is integral to the engine’s cooling system, ensuring efficient water flow and temperature regulation.

ISL9 Engines

The ISL9 engine series, known for its robust performance and reliability, incorporates the Compressor Water Outlet Tube. This part is essential in maintaining optimal engine temperatures by facilitating the proper flow of coolant from the compressor to the water outlet.

CM2150 Engines

Similarly, the CM2150 engine series, which is engineered for heavy-duty applications, also utilizes the Compressor Water Outlet Tube. This component ensures that the coolant is effectively managed, contributing to the engine’s longevity and efficiency.

SN Engines

The SN engine series, recognized for its versatility and power, is another beneficiary of the Compressor Water Outlet Tube. This part plays a role in the engine’s cooling system, ensuring that the coolant is efficiently circulated and that the engine operates within its optimal temperature range.

By integrating the Compressor Water Outlet Tube into these engine models, Cummins ensures that the cooling system functions effectively, thereby enhancing the overall performance and reliability of the engines.

Role of the Compressor Water Outlet Tube in Engine Systems

The Compressor Water Outlet Tube is an essential component in the arrangement of engine systems, specifically within the compressor coolant circuit. This tube facilitates the efficient flow of coolant from the compressor, ensuring that the system maintains optimal operating temperatures.

In the compressor coolant arrangement, the tube connects to the compressor outlet, allowing coolant to exit the compressor and travel to the next stage of the cooling process. This connection is vital for dissipating heat generated during compression, which if not managed properly, could lead to reduced efficiency and potential damage to the compressor.

The tube’s design ensures a secure fit within the engine system, preventing leaks and maintaining the integrity of the coolant flow. Its placement is strategically aligned with other components to ensure smooth operation and minimal resistance in the coolant path.

Overall, the Compressor Water Outlet Tube plays a significant role in maintaining the performance and longevity of the engine system by ensuring effective heat management within the compressor coolant circuit.

Conclusion

The Compressor Water Outlet Tube, part number 4994815, is a critical component in the cooling system of Cummins engines. Its role in facilitating efficient coolant flow and maintaining optimal engine temperatures is essential for the performance and longevity of heavy-duty trucks. Proper installation, maintenance, and understanding of its function are key to ensuring the reliability and efficiency of the engine system.

-

Dixon, John C. Tyres Suspension and Handling Second Edition. SAE International, 1996.

↩ -

Schneider, Wolf-Henning. Pistons and Engine Testing. Springer Nature, 2016.

↩ -

Randall, Martynn. Haynes Manual on Diesel Engines. Haynes Publishing, 2015.

↩ -

Huzij, Robert; Spano, Angelo; Bennett, Sean. Modern Diesel Technology: Heavy Equipment Systems. Cengage Learning, 2019.

↩ -

Cummins Inc. QSN14 CM876 N103, Service Manual (4358358).

↩ -

Cummins Inc. QSN14 CM876 N103, Service Manual (4358358).

↩

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.