This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

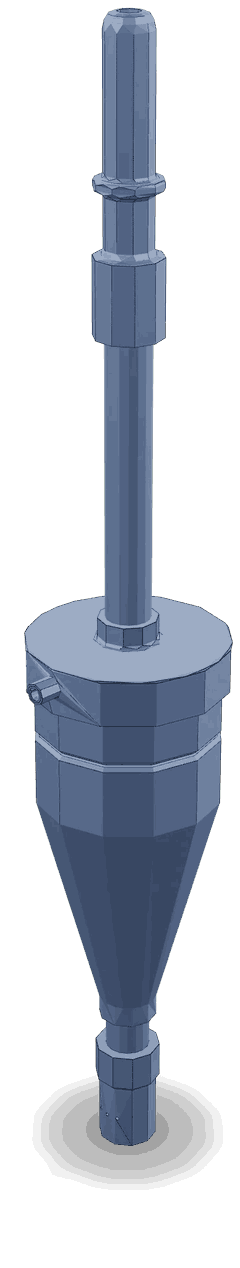

The Cummins 4999800 Doser Injector is a specialized component designed for use in heavy-duty trucks. Its primary function is to inject diesel exhaust fluid (DEF) into the exhaust stream, which plays a role in reducing nitrogen oxide (NOx) emissions. This Cummins part is significant in the operation of heavy-duty trucks as it helps meet stringent emissions regulations while maintaining engine performance.

Basic Concepts of Doser Injectors

A doser injector is a device that precisely injects DEF into the exhaust stream of a diesel engine. This process, known as selective catalytic reduction (SCR), converts NOx into harmless nitrogen and water vapor 1. The doser injector works in conjunction with the engine’s electronic control unit (ECU) to monitor and adjust the amount of DEF injected based on engine load, speed, and other operating conditions. This system is integral to modern emissions control strategies in diesel engines.

Purpose of the Cummins 4999800 Doser Injector

The Cummins 4999800 Doser Injector is designed to enhance the emissions control system in heavy-duty trucks. By injecting DEF into the exhaust stream, it facilitates the SCR process, which reduces NOx emissions. This injector also contributes to maintaining engine performance by ensuring that the emissions control system operates efficiently. Its role is vital in helping trucks comply with environmental regulations while optimizing engine output.

Key Features

The Cummins 4999800 Doser Injector incorporates several key features that enhance its performance and durability. These include a robust design that withstands high temperatures and pressures within the exhaust system. The injector is constructed from high-quality materials to ensure longevity and reliability. Additionally, it incorporates advanced technological features such as precise control algorithms and feedback mechanisms to maintain optimal DEF injection rates.

Benefits

Using the Cummins 4999800 Doser Injector offers several benefits. It contributes to improved fuel efficiency by ensuring that the emissions control system operates smoothly without adding unnecessary load to the engine. Reduced emissions are another significant advantage, as the injector helps trucks meet or exceed regulatory standards. Furthermore, the injector enhances engine longevity by maintaining efficient emissions control, which can reduce wear and tear on other engine components.

Installation and Integration

Proper installation of the Cummins 4999800 Doser Injector is crucial for its effective operation. It should be installed according to the manufacturer’s guidelines to ensure it is securely mounted and correctly aligned within the exhaust system. Integration with the truck’s ECU is also important, as this allows the injector to communicate with the engine’s control system for optimal performance. Any necessary preparations or adjustments should be made to ensure seamless operation.

Troubleshooting and Maintenance

Regular maintenance and troubleshooting are important to ensure the Cummins 4999800 Doser Injector operates effectively. Common issues may include clogged injector nozzles or malfunctioning control systems. Routine checks and cleaning can help prevent these problems. Additionally, monitoring the DEF injection rates and ensuring the injector is functioning within specified parameters can help maintain optimal performance and longevity.

Cummins Overview

Cummins Inc. is a global power leader that designs, manufactures, and distributes engines, filtration, and power generation products. With a history spanning over a century, Cummins has established a reputation for innovation and quality in the automotive and heavy-duty truck industries. The company is committed to developing advanced technologies that enhance engine performance, efficiency, and environmental sustainability.

Compatibility of Doser Injector Part 4999800 with Cummins Engines

The Doser Injector part 4999800, manufactured by Cummins, is designed to be compatible with a range of Cummins engines. This part is integral to the engine’s fuel injection system, ensuring precise fuel delivery and optimal engine performance. Below is a detailed look at the compatibility of this part with various Cummins engines:

ISB/ISD Series

- ISB/ISD 4.5 CM2150 B119

- ISB/ISD 6.7 CM2150 SN

The Doser Injector part 4999800 is specifically engineered to fit within the ISB/ISD series engines. These engines are known for their robust performance and reliability, making them suitable for a variety of applications, from commercial vehicles to industrial machinery. The doser injector ensures that the fuel is delivered in a controlled manner, enhancing the engine’s efficiency and reducing emissions.

ISBE Series

- ISBE CM2150

- ISBE4 CM850

The ISBE series engines benefit from the precision of the Doser Injector part 4999800. These engines are typically used in heavy-duty applications, where consistent and reliable performance is crucial. The doser injector’s role in these engines is to maintain the delicate balance of fuel delivery, ensuring smooth operation and longevity of the engine.

ISL Series

- ISL9 CM2150 SN

- ISL9.5 CM2880 L138

The ISL series engines are designed for high-performance applications, and the Doser Injector part 4999800 is a critical component in these setups. This part ensures that the fuel is injected at the right time and in the right quantity, maximizing power output and fuel efficiency. The doser injector’s precision is essential for the ISL series engines to deliver their best performance.

ISM Series

- ISM11 CM876 SN

The ISM11 engine, paired with the Doser Injector part 4999800, is optimized for applications requiring high torque and durability. This engine is often found in construction and agricultural equipment, where reliability and power are paramount. The doser injector ensures that the engine operates smoothly, providing the necessary power without compromising on efficiency.

ISZ Series

- ISZ13 CM2150 Z105

The ISZ13 engine, when equipped with the Doser Injector part 4999800, is designed for applications that demand a balance of power and fuel efficiency. This engine is commonly used in medium-duty trucks and buses, where the doser injector plays a crucial role in maintaining optimal fuel delivery and reducing emissions.

By ensuring compatibility with these various Cummins engines, the Doser Injector part 4999800 helps maintain the high standards of performance and reliability that Cummins engines are known for.

Role of Part 4999800 Doser Injector in Aftertreatment Systems

The part 4999800 doser injector is an integral component within the aftertreatment system of modern engines, specifically designed to enhance the efficiency of emissions control. This component works in concert with various other elements to ensure that the exhaust gases meet environmental regulations.

When the doser injector is activated, it precisely meters and injects a reducing agent, commonly Diesel Exhaust Fluid (DEF), into the exhaust stream. This injection occurs upstream of the Selective Catalytic Reduction (SCR) catalyst. The reducing agent reacts with nitrogen oxides (NOx) in the exhaust, converting them into harmless nitrogen and water vapor 1.

The doser injector’s operation is controlled by the engine’s Electronic Control Unit (ECU), which monitors various parameters such as exhaust temperature, engine load, and NOx sensor readings. The ECU determines the optimal amount of reducing agent required and signals the doser injector to dispense the appropriate quantity.

In the aftertreatment device, the doser injector plays a significant role by ensuring that the SCR catalyst operates within its optimal temperature and chemical environment. This, in turn, maximizes the catalyst’s efficiency in reducing NOx emissions.

The integration of the doser injector within the aftertreatment system also involves coordination with other components such as the fluid doser, which supplies the reducing agent to the injector, and various sensors that provide feedback to the ECU regarding the system’s performance.

Overall, the doser injector is a key player in the aftertreatment system, working seamlessly with other components to maintain efficient and compliant emissions control in modern engine systems.

Conclusion

The Cummins 4999800 Doser Injector is a critical component in the emissions control system of heavy-duty trucks. By precisely injecting DEF into the exhaust stream, it facilitates the SCR process, which significantly reduces NOx emissions. This part ensures that trucks comply with stringent environmental regulations while maintaining optimal engine performance. Its robust design, advanced features, and compatibility with various Cummins engines make it an essential component for modern diesel engines.

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.