This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

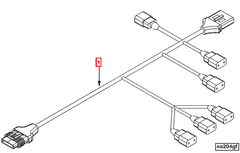

The Cummins 5254715 Wiring Harness is a specialized component designed for use in commercial trucks. It serves as a vital link in the electrical system, facilitating the connection between various electrical components and ensuring the proper transmission of signals throughout the vehicle. Its role is significant in maintaining the operational efficiency and reliability of the truck’s electrical systems 1.

Basic Concepts of Wiring Harnesses

A wiring harness is an assembly of wires, connectors, and terminals that transmit electrical power and signals to and from various components within a vehicle. It is designed to organize and protect the wires, reducing the risk of damage and ensuring efficient signal transmission. Within a vehicle’s electrical system, the wiring harness plays a role by providing a structured pathway for electricity to flow, thereby enabling the operation of lights, sensors, and other electrical components 2.

Purpose of the 5254715 Wiring Harness

This Cummins part is specifically engineered to integrate seamlessly into the electrical system of a truck. It connects various electrical components, ensuring that signals and power are transmitted accurately and efficiently. This harness plays a role in maintaining the electrical integrity of the truck, supporting functions such as engine management, lighting, and sensor operations 3.

Key Features

The 5254715 is characterized by its robust design and the use of high-quality materials. It is constructed to withstand the demanding conditions typically encountered in commercial truck operations. Features such as corrosion-resistant materials and durable connectors enhance its performance and longevity. Additionally, the harness is designed with flexibility in mind, allowing for easy installation and integration into the truck’s existing electrical system.

Benefits

The use of the 5254715 offers several advantages. It contributes to improved reliability by ensuring stable and consistent electrical connections. This reduces the risk of electrical faults that could lead to system failures. Furthermore, the harness enhances the overall performance of the truck’s electrical system, supporting efficient operation of all connected components.

Installation Considerations

Proper installation of the 5254715 is key to ensuring its optimal performance and longevity. It is important to follow manufacturer guidelines closely, paying attention to specific requirements such as secure connections and proper routing of wires to avoid damage. Taking these precautions during installation helps maintain the integrity of the electrical system and ensures the harness functions as intended.

Troubleshooting and Maintenance

Regular maintenance and prompt troubleshooting are important for the longevity and reliability of the 5254715. Common issues may include loose connections or damaged wires, which can be diagnosed through visual inspection and testing. Addressing these issues promptly can prevent more serious electrical problems. Maintenance practices such as periodic inspection and cleaning of connections can help prolong the lifespan of the harness and ensure continued reliable operation.

Cummins Overview

Cummins Inc. is a global power leader that designs, manufactures, and distributes a wide range of power solutions. With a strong reputation in the industry, Cummins is known for its commitment to quality and innovation. The company’s extensive product line includes engines, filtration, emissions solutions, and power generation products, all designed to meet the demanding needs of commercial and industrial applications. Cummins’ dedication to excellence is reflected in its products, including the 5254715, which is engineered to deliver reliable performance in commercial truck applications.

Cummins Wiring Harness 5254715 Compatibility

The Cummins Wiring Harness part number 5254715 is designed to integrate seamlessly with a range of Cummins engines, ensuring reliable electrical connectivity and performance. This wiring harness is engineered to fit specific engine models, providing a robust solution for maintaining the integrity of the electrical system.

QSM11 Engines

For the QSM11 series engines, the wiring harness 5254715 is a component that ensures all electrical connections are properly managed. This harness is tailored to fit the unique layout and requirements of the QSM11 engines, facilitating smooth operation and reducing the risk of electrical faults.

CM570 Engines

Similarly, the CM570 engines benefit from the precise design of the 5254715 wiring harness. This part is crafted to align with the specific electrical architecture of the CM570 engines, ensuring that all sensors, actuators, and control modules are effectively connected. The harness is engineered to withstand the operational stresses of these engines, providing a durable and reliable solution.

Grouping of Engines

When considering the compatibility of the 5254715 wiring harness, it is essential to recognize that both the QSM11 and CM570 engines share certain design principles and electrical requirements. This commonality allows the harness to be a versatile component across these engine models, simplifying maintenance and repair processes. The harness is designed to interface with the engine’s control units, sensors, and other electrical components, ensuring that the engine operates efficiently and reliably.

Role of Part 5254715 Wiring Harness in Engine Systems

The 5254715 Wiring Harness is an integral component that facilitates the electrical connections within various engine systems. It serves as the backbone for the electrical infrastructure, ensuring seamless communication and power distribution among different parts of the engine.

Integration with Control Panel Wiring

The wiring harness is meticulously designed to interface with the control panel wiring. This integration allows for the efficient transmission of signals and power from the control panel to various engine components. It ensures that commands from the control panel are accurately and promptly relayed to actuators, sensors, and other critical systems, maintaining the engine’s operational integrity.

Role in the Electrical Package

Within the electrical package, the 5254715 Wiring Harness plays a pivotal role in organizing and routing wires. It helps in reducing the complexity of the electrical system by consolidating multiple wires into a single, manageable unit. This not only enhances the reliability of the electrical connections but also simplifies troubleshooting and maintenance procedures.

Facilitation of Product Installation

During the product installation phase, the wiring harness significantly streamlines the process. Its pre-assembled nature means that it can be quickly integrated into the engine system, reducing installation time and labor costs. The harness is designed to fit snugly into designated spaces within the engine compartment, ensuring that all connections are secure and well-protected from environmental factors.

Ensuring System Cohesion

By providing a structured pathway for electrical signals and power, the 5254715 Wiring Harness ensures that all engine components operate in unison. It supports the functionality of sensors by delivering consistent power and signal integrity, which is essential for accurate data collection and system feedback. Additionally, it powers actuators and other control elements, enabling precise engine management and performance optimization.

Conclusion

In summary, the 5254715 Wiring Harness is a fundamental element that enhances the efficiency, reliability, and ease of maintenance of engine systems. Its role in connecting and powering various components underscores its importance in the overall functionality of the engine.

-

Eret, A. (2024). Dynamic and Fatigue Assessment of Heavy-Duty Engine Valves. Springer Nature.

↩ -

Huzij, R., Spano, A., & Bennett, S. (2019). Modern Diesel Technology: Heavy Equipment Systems. Cengage Learning.

↩ -

Dixon, J. (2010). Modern Diesel Technology Preventive Maintenance and Inspection. Delmar Cengage Learning.

↩

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.