This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

The Turbo Oil Drain Tube, part number 5255610, manufactured by Cummins, is a component designed for use in heavy-duty trucks. It is integral to the operation of the turbocharger system, contributing to the efficient and reliable performance of the engine.

Basic Concepts of Turbo Oil Drain Tubes

A Turbo Oil Drain Tube is a component within the turbocharger system that facilitates the drainage of oil from the turbocharger. This tube plays a role in maintaining the lubrication and cooling of the turbocharger, which are vital for the turbocharger’s performance and longevity. By ensuring that excess oil is efficiently drained away, the tube helps to maintain optimal operating conditions within the turbocharger 1.

Purpose of the Turbo Oil Drain Tube

The Turbo Oil Drain Tube is designed to play a specific role in the operation of a truck’s engine. It functions within the turbocharger system to facilitate the drainage of oil, which is crucial for the lubrication and cooling of the turbocharger. This drainage process helps to prevent oil buildup, which could otherwise lead to increased friction and heat within the turbocharger, potentially affecting its performance and lifespan 2.

Key Features

The Turbo Oil Drain Tube is constructed with features that enhance its performance and durability. It is made from materials that are resistant to the high temperatures and pressures within the turbocharger system. The design includes specific connection types that ensure a secure fit within the system. Additionally, the tube may incorporate unique attributes such as reinforced sections or specialized coatings to further improve its resilience and functionality 3.

Benefits

The Turbo Oil Drain Tube offers several advantages. It contributes to improved turbocharger efficiency by ensuring proper oil drainage, which helps maintain the turbocharger’s lubrication and cooling. This can lead to reduced maintenance requirements, as the turbocharger is less likely to suffer from issues related to oil buildup. Furthermore, the tube enhances engine reliability by supporting the turbocharger’s optimal operation.

Installation Process

Installing the Turbo Oil Drain Tube involves several steps to ensure a secure and effective fit. Preparatory steps may include cleaning the installation area and inspecting the tube for any damage. The installation process requires specific tools, and it is important to follow best practices to ensure that the tube is correctly positioned and connected within the turbocharger system.

Troubleshooting Common Issues

Common problems associated with Turbo Oil Drain Tubes can include leaks or blockages. These issues can often be diagnosed through visual inspection or by monitoring the turbocharger’s performance. Resolution methods may involve cleaning the tube, repairing or replacing damaged sections, or ensuring that connections are secure and properly sealed.

Maintenance Tips

Regular maintenance practices are important for ensuring the longevity and optimal performance of the Turbo Oil Drain Tube. This includes inspecting the tube at recommended intervals for signs of wear or damage, and cleaning it as necessary to remove any buildup that could affect its function. Following these maintenance tips can help to prevent issues and ensure that the turbocharger system operates efficiently.

Cummins: A Brief Overview

Cummins Inc. is a well-established company with a significant presence in the automotive and heavy-duty truck industries. The company has a history of innovation and quality, offering a wide range of products designed to meet the demanding requirements of these sectors. Cummins is recognized for its commitment to excellence and its contributions to the advancement of engine technology.

Turbo Oil Drain Tube (Part 5255610) Compatibility with Cummins Engines

The Turbo Oil Drain Tube, identified by part number 5255610 and manufactured by Cummins, is a critical component in the maintenance and operation of several Cummins engine models. This part is essential for the proper functioning of the engine’s turbo system, ensuring that oil is effectively drained from the turbocharger, preventing oil accumulation that could lead to performance issues or damage.

QSB6.7 CM2250 Engine Group

The Turbo Oil Drain Tube (5255610) is specifically designed to fit within the QSB6.7 CM2250 engine group. This engine group is known for its robust performance and reliability, making it a popular choice in various applications, including industrial, marine, and agricultural sectors. The integration of the Turbo Oil Drain Tube in these engines ensures that the turbocharger operates efficiently, maintaining optimal performance and longevity.

The Turbo Oil Drain Tube’s design allows it to seamlessly integrate with the engine’s oil system, providing a clear path for oil to flow from the turbocharger back to the engine’s oil sump. This is crucial for maintaining the correct oil level within the turbocharger and preventing oil starvation, which can cause the turbocharger to fail prematurely.

By ensuring that the Turbo Oil Drain Tube is correctly installed and functioning, engine operators can maintain the health and efficiency of their QSB6.7 CM2250 engines, avoiding potential downtime and costly repairs. This part’s compatibility with the QSB6.7 CM2250 engine group underscores Cummins’ commitment to providing high-quality, reliable components that enhance engine performance and durability.

Role of Part 5255610 Turbo Oil Drain Tube in Engine Systems

The Turbo Oil Drain Tube is an essential component in the efficient operation of turbocharger systems within various engine setups. Its primary function is to facilitate the drainage of oil from the turbocharger, ensuring that excess oil does not accumulate and potentially cause performance issues.

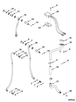

In the context of turbocharger plumbing, the Turbo Oil Drain Tube is integrated into the oil return system. It connects the turbocharger to the engine’s oil sump, allowing used oil to be efficiently returned after lubricating the turbocharger’s moving parts. This process is vital for maintaining optimal lubrication and preventing oil starvation, which can lead to increased wear and reduced efficiency.

When considering the turbocharger itself, the Turbo Oil Drain Tube plays a supportive role by ensuring that the oil supply system remains balanced. The turbocharger relies on a consistent flow of oil to lubricate its bearings and other internal components. The drain tube helps manage this flow by providing a clear path for the return of oil, thus preventing any buildup that could impede performance.

In the broader scope of plumbing within the engine system, the Turbo Oil Drain Tube is a key element that contributes to the overall integrity of the oil management system. It works in conjunction with other components such as oil filters, pumps, and coolers to ensure that the oil remains clean and at the appropriate temperature. This, in turn, supports the longevity and reliability of the turbocharger and the engine as a whole.

Overall, the integration of the Turbo Oil Drain Tube within these systems underscores its importance in maintaining the health and performance of turbocharged engines.

Conclusion

The Turbo Oil Drain Tube, part number 5255610, is a critical component in the maintenance and operation of Cummins engines, particularly within the QSB6.7 CM2250 engine group. Its role in facilitating the drainage of oil from the turbocharger ensures that the engine operates efficiently and reliably. By understanding the importance of this part and following proper installation, maintenance, and troubleshooting practices, engine operators can ensure the longevity and performance of their turbocharged engines.

-

Garrett, T.K., Newton, K., & Steeds, W. (2001). The Motor Vehicle. Reed Educational and Professional Publishing Ltd.

↩ -

Bari, S. (2013). Diesel Engine Combustion, Emissions and Condition Monitoring. InTech.

↩ -

Osgood, L., Cameron, G., & Christensen, E. (2024). Engineering Mechanics: Statics. Creative Commons.

↩

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.