5255624

Injector Fuel Supply Tube

Cummins®

AVAILABLE

1 is currently available

Ships within 2-4 business days

This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

The 5255624 Injector Fuel Supply Tube, manufactured by Cummins, is a vital component in the operation of commercial trucks. Cummins, a well-established name in the commercial truck industry, produces a range of high-quality engine components designed to enhance the performance and reliability of diesel engines. This Cummins part is integral to the fuel system, ensuring efficient fuel delivery to the injectors, which is crucial for the optimal functioning of the engine.

Basic Concepts of Injector Fuel Supply Tubes

An Injector Fuel Supply Tube is a component within the fuel system responsible for transporting fuel from the fuel tank to the injectors. Its function is to provide a consistent and pressurized flow of fuel, ensuring that the injectors receive the necessary amount of fuel for combustion. This component plays a role in the overall performance of a diesel engine by facilitating efficient fuel delivery, which is essential for maintaining engine power and fuel efficiency 1.

Purpose of the Injector Fuel Supply Tube

The Injector Fuel Supply Tube is designed to deliver fuel to the injectors in a commercial truck’s diesel engine. It ensures that fuel is supplied under the correct pressure and in the right quantity, which is necessary for the injectors to atomize the fuel properly. This atomization is vital for efficient combustion, which in turn affects the engine’s performance, fuel economy, and emissions 2.

Key Features

The Injector Fuel Supply Tube boasts several key features that enhance its performance. It is constructed from high-quality materials that offer durability and resistance to the corrosive effects of diesel fuel. The design includes precise engineering to ensure a secure fit within the fuel system, minimizing the risk of leaks. Additionally, the tube may feature unique characteristics such as reinforced sections to withstand high pressure and specialized coatings to prevent wear and corrosion 3.

Benefits

Using the Injector Fuel Supply Tube offers several benefits. It provides improved fuel delivery efficiency, ensuring that the injectors receive a consistent supply of fuel. This results in more efficient combustion and better engine performance. The tube’s durable construction contributes to its longevity, reducing the need for frequent replacements. Furthermore, its reliable design enhances the overall reliability of the fuel system, leading to fewer disruptions in engine operation 4.

Installation Process

Installing the Injector Fuel Supply Tube requires careful attention to detail. Begin by ensuring the engine is turned off and the fuel system is depressurized. Use the appropriate tools to disconnect the old tube from the fuel system. Carefully align the new tube with the fuel lines and secure it in place using the provided fittings. Ensure all connections are tight to prevent leaks. Finally, repressurize the fuel system and check for any leaks before starting the engine.

Troubleshooting Common Issues

Common issues with the Injector Fuel Supply Tube may include leaks or blockages. If a leak is detected, inspect the connections and fittings for tightness. Replace any damaged sections of the tube as necessary. Blockages can be addressed by flushing the fuel system to remove any contaminants. Regular maintenance and inspection can help identify and resolve these issues before they lead to more significant problems.

Maintenance Tips

To ensure the optimal performance and longevity of the Injector Fuel Supply Tube, regular maintenance is recommended. Inspect the tube and its connections periodically for signs of wear or damage. Clean the tube and surrounding components to prevent the buildup of contaminants. Additionally, follow the manufacturer’s guidelines for fuel system maintenance to ensure all components are functioning correctly.

Role in Fuel System Efficiency

The Injector Fuel Supply Tube contributes to the efficiency of the fuel system by ensuring a consistent and pressurized flow of fuel to the injectors. This consistent supply is crucial for proper fuel atomization, which enhances the combustion process. Efficient combustion leads to better engine performance, improved fuel economy, and reduced emissions, making the tube a key component in the overall efficiency of the fuel system.

About Cummins

Cummins Inc. is a global power leader that designs, manufactures, and distributes a wide range of power solutions, including engines, filtration, and related technologies. With a history spanning over a century, Cummins has established a reputation for producing high-quality, reliable components for the commercial truck industry. Their product range includes engines, powertrains, and aftermarket parts, all designed to meet the demanding requirements of commercial applications.

Cummins Injector Fuel Supply Tube (Part 5255624)

The Cummins Injector Fuel Supply Tube, identified by the part number 5255624, is a critical component in the fuel delivery system of several Cummins diesel engines. This part is designed to ensure the efficient and reliable transfer of fuel from the fuel pump to the fuel injectors, which is essential for maintaining optimal engine performance.

Compatibility with Cummins Engines

The Injector Fuel Supply Tube (5255624) is specifically engineered to fit the following Cummins diesel engines:

- QSB4.5 CM2250 EC

- QSB6.7 CM2250

These engines are part of Cummins’ QSB series, which is known for its durability and reliability in various applications, including industrial, marine, and agricultural sectors. The injector fuel supply tube is a key part in ensuring that these engines operate smoothly by providing a consistent and unobstructed fuel flow to the injectors.

Importance in Engine Performance

The injector fuel supply tube plays a pivotal role in the overall efficiency and performance of the engine. It is responsible for:

- Ensuring a steady and uninterrupted fuel supply to the injectors.

- Maintaining the integrity of the fuel system by preventing leaks and contamination.

- Contributing to the engine’s ability to deliver consistent power output.

By integrating seamlessly with the fuel delivery system of the QSB4.5 CM2250 EC and QSB6.7 CM2250 engines, the injector fuel supply tube helps to maintain the high standards of performance and reliability that Cummins engines are known for.

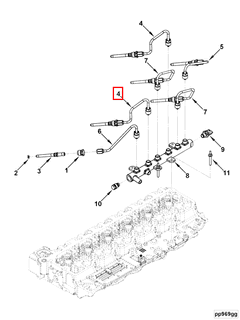

Role of Part 5255624 Injector Fuel Supply Tube in Engine Systems

The Injector Fuel Supply Tube, identified by part number 5255624, is an integral component in the fuel delivery system of an engine. Its primary function is to transport fuel from the fuel rail to the injectors, ensuring a consistent and precise fuel supply for combustion.

Integration with Engine Components

-

Injector Plumbing: The Injector Fuel Supply Tube is a key element in the injector plumbing system. It connects the fuel rail to the injectors, facilitating the smooth flow of fuel. This connection is vital for maintaining the correct fuel pressure and flow rate, which are essential for the injectors to operate efficiently.

-

Injectors: Directly linked to the injectors, the fuel supply tube ensures that each injector receives an equal and regulated amount of fuel. This uniformity is important for balanced combustion across all cylinders, contributing to overall engine performance and efficiency.

-

Fuel Rail: The tube extends from the fuel rail, which acts as a distribution manifold for fuel. The fuel rail supplies fuel to all injectors simultaneously, and the Injector Fuel Supply Tube plays a role in this distribution network by providing a dedicated pathway for fuel to reach each injector.

-

Camshaft and Valve Timing: Although not directly connected, the efficient operation of the Injector Fuel Supply Tube influences the timing and delivery of fuel, which in turn affects the combustion process. Proper fuel delivery is synchronized with the camshaft’s operation, ensuring that fuel is injected at the optimal moment in the engine cycle.

-

Connecting Rod and Piston: The performance of the connecting rod and piston is indirectly affected by the Injector Fuel Supply Tube. Consistent and precise fuel delivery leads to more controlled and efficient combustion, which translates to smoother operation and potentially enhanced performance of these components.

-

Overall Engine Performance: The Injector Fuel Supply Tube contributes to the engine’s overall performance by ensuring that the fuel system operates within specified parameters. This includes maintaining the correct fuel pressure, flow rate, and distribution, all of which are essential for optimal engine operation.

Conclusion

In summary, the Injector Fuel Supply Tube (part 5255624) is a vital component in the fuel delivery system, playing a significant role in ensuring efficient and consistent fuel supply to the injectors, which is fundamental for the engine’s performance and reliability.

-

Hilgers, Michael. Electrical Systems and Mechatronics, Second Edition. Springer Vieweg, 2023.

↩ -

Mollenhauer, Klaus, and Helmut Tschoeke. Handbook of Diesel Engines. Springer, 2010.

↩ -

Reif, Konrad, ed. Gasoline Engine Management Systems and Components. Springer Vieweg, 2015.

↩ -

Goodnight, Nicholas, and Kirk VanGelder. Automotive Braking Systems CDX Master Automotive Technician Series. Jones Bartlett Learning, 2019.

↩

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.