5255744

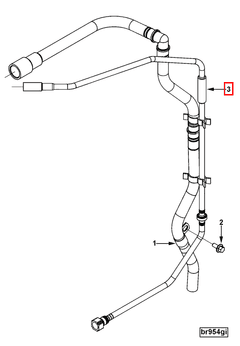

Lubricating Oil Drain Tube

Cummins®

IN STOCK

3 are currently available

Ships within 1 business day

This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

Introduction

The Lubricating Oil Drain Tube (5255744) by Cummins is a critical component for the maintenance of commercial trucks. It facilitates the draining of used lubricating oil from the engine, ensuring that the engine operates with fresh oil, which is essential for maintaining engine efficiency and longevity. This component is integral to the routine maintenance procedures of commercial trucks, contributing to the overall reliability and performance of the vehicle.

Function and Operation

The Lubricating Oil Drain Tube operates within the engine system by providing a pathway for the used oil to exit the engine. When the drain valve is opened, the used oil flows through the tube and out of the engine. This process is a standard part of the oil change procedure, which is essential for removing contaminants and degraded oil that can impair engine performance. The tube is designed to handle the flow of oil efficiently, minimizing the risk of spills and ensuring that the oil is directed to the appropriate collection container.

Key Features

The Lubricating Oil Drain Tube is characterized by its robust design and material selection, which contribute to its durability and efficiency. Constructed from high-quality materials, the tube is resistant to corrosion and capable of withstanding the pressures and temperatures associated with engine oil drainage. Its design ensures a secure fit within Cummins engines, promoting compatibility and ease of use during maintenance procedures.

Benefits of Using the Lubricating Oil Drain Tube

Incorporating the Lubricating Oil Drain Tube into truck maintenance routines offers several advantages. By facilitating the efficient drainage of used oil, it contributes to improved engine performance and longevity. Regular oil changes, made easier with this tube, help maintain engine cleanliness, reduce wear, and enhance fuel efficiency. Additionally, the tube’s design minimizes the mess associated with oil changes, making the process more convenient for maintenance personnel.

Installation Process

Installing the Lubricating Oil Drain Tube involves several steps to ensure proper fitting and function. First, the engine oil must be allowed to cool to prevent burns and reduce the risk of spills. Then, the existing drain plug or tube should be removed, and the new Lubricating Oil Drain Tube should be inserted into the drain port. It is important to use the correct tools for this process to avoid damaging the engine or the tube. Once installed, the tube should be secured according to the manufacturer’s instructions to ensure a tight seal.

Maintenance and Troubleshooting

To maintain the Lubricating Oil Drain Tube, it is important to check for any signs of wear or damage before each use. Common issues may include leaks or blockages, which can be addressed by inspecting the tube for debris or corrosion and cleaning or replacing it as necessary. Regular maintenance of the tube ensures that it continues to function effectively, contributing to the overall efficiency of the oil change process.

Safety Considerations

When working with the Lubricating Oil Drain Tube, it is important to follow safety practices to protect oneself and the environment. Used oil should be handled carefully to avoid spills, and appropriate personal protective equipment should be worn. Disposal of used oil must comply with local regulations to prevent environmental harm. Additionally, the tube should be installed and used in accordance with the manufacturer’s guidelines to ensure safe operation.

Cummins: A Brief Overview

Cummins Inc. is a global power leader that designs, manufactures, and distributes a wide range of power solutions, including diesel and natural gas engines, as well as related technologies. With a history spanning over a century, Cummins is committed to innovation, quality, and customer satisfaction. The company’s product range includes engines, filtration, emissions solutions, and power systems, all designed to meet the demanding requirements of commercial and industrial applications. Cummins’ dedication to advancing technology and sustainability in the power industry underscores its position as a leader in the market. 1

Cummins Engine Compatibility with Lubricating Oil Drain Tube Part 5255744

The Cummins lubricating oil drain tube part number 5255744 is designed to fit a variety of Cummins engines, ensuring efficient oil drainage and maintenance. This part is compatible with the following engines:

ISL9 Series

- ISL9 CM2150 SN

- ISL9.5 CM2880 L138

These engines, part of the ISL9 series, benefit from the precise fit and functionality of the lubricating oil drain tube part 5255744. This ensures that oil is effectively drained from the engine, maintaining optimal lubrication levels and preventing oil contamination.

QSL9 Series

- QSL8.9 CM2150 L141

- QSL9 CM850 (CM2850)

The QSL9 series engines, including the QSL8.9 CM2150 L141 and QSL9 CM850 (CM2850), also utilize the lubricating oil drain tube part 5255744. This part is engineered to fit seamlessly with these engines, facilitating proper oil drainage and contributing to the overall efficiency and longevity of the engine.

By ensuring compatibility with these engines, the lubricating oil drain tube part 5255744 plays a crucial role in maintaining engine health and performance.

Role of Part 5255744 Lubricating Oil Drain Tube in Engine Systems

The lubricating oil drain tube, part 5255744, is a critical component in maintaining the efficiency and longevity of various engine systems. Its primary function is to facilitate the removal of used lubricating oil from the crankcase, ensuring that the engine operates with fresh oil, which is vital for reducing friction and wear on moving parts.

Integration with the Crankcase

In the crankcase, the lubricating oil drain tube is strategically positioned to allow for the efficient drainage of oil. This is particularly important during oil changes, as it ensures that the old oil is completely removed, minimizing contamination of the new oil. The tube’s design allows for a smooth flow of oil, reducing the risk of spills and ensuring that the crankcase is thoroughly emptied.

Interaction with the Breather System

The breather system plays a role in maintaining the pressure balance within the crankcase. The lubricating oil drain tube works in conjunction with the breather to ensure that the crankcase remains at an optimal pressure. During oil changes, the breather allows air to enter the crankcase as oil is drained out, preventing a vacuum from forming and ensuring a steady flow of oil through the drain tube.

Compatibility with Engine Brake (12V) Kit

For engines equipped with an engine brake (12V) kit, the lubricating oil drain tube is equally important. The engine brake system relies on efficient oil management to function correctly. The drain tube ensures that the oil used in the engine brake system is regularly refreshed, maintaining the system’s performance and reliability. Proper drainage also helps in preventing oil contamination, which could otherwise affect the engine brake’s efficiency.

Conclusion

In summary, the Lubricating Oil Drain Tube (5255744) by Cummins is a key component in the maintenance of engine systems, working seamlessly with the crankcase, breather system, and engine brake (12V) kit to ensure optimal engine performance and longevity. Its robust design, ease of installation, and compatibility with various Cummins engines make it an essential part of routine maintenance procedures for commercial trucks.

-

Cummins Inc. is a global power leader that designs, manufactures, and distributes a wide range of power solutions, including diesel and natural gas engines, as well as related technologies. With a history spanning over a century, Cummins is committed to innovation, quality, and customer satisfaction. The company’s product range includes engines, filtration, emissions solutions, and power systems, all designed to meet the demanding requirements of commercial and industrial applications. Cummins’ dedication to advancing technology and sustainability in the power industry underscores its position as a leader in the market.

↩

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.