5261953

Compressor Air Inlet Tube

Cummins®

IN STOCK

6 are currently available

Ships within 1 business day

This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

The Compressor Air Inlet Tube, part number 5261953, is a component manufactured by Cummins, a prominent name in the commercial truck industry. This part is significant in the operation of commercial trucks, contributing to the efficiency and reliability of the vehicle’s air compressor system.

Basic Concepts of Compressor Air Inlet Tubes

A Compressor Air Inlet Tube is a component that facilitates the intake of air into the compressor system of a truck. Its function is to direct ambient air into the compressor, where it is pressurized and used for various applications such as braking systems and pneumatic tools. The efficiency of this component directly influences the overall performance of the truck’s air compressor system 1.

Role of the Compressor Air Inlet Tube in Truck Operation

The Compressor Air Inlet Tube plays a specific role in the operation of a truck by ensuring a steady and unobstructed flow of air into the compressor. It interacts with other components of the air compressor system, such as the compressor itself and the air filter, to maintain optimal air pressure levels necessary for the truck’s operations 2.

Key Features of the Compressor Air Inlet Tube

The Compressor Air Inlet Tube is characterized by several key features that enhance its performance and durability. These include its material composition, which is designed to withstand the harsh conditions of commercial truck environments, and its design elements that ensure efficient air flow. Unique characteristics such as its robust construction and precise engineering contribute to its reliability and longevity 3.

Benefits of Using the Compressor Air Inlet Tube

Utilizing the Compressor Air Inlet Tube offers several benefits. It improves air flow into the compressor, leading to enhanced compressor efficiency. This can result in potential cost savings for fleet operators due to reduced maintenance needs and improved system reliability. Additionally, the efficient operation of the air compressor system can contribute to overall fuel efficiency of the truck.

Installation Considerations

Proper installation of the Compressor Air Inlet Tube is crucial for its effective operation. It is important to ensure compatibility with the specific truck model and to follow any specific installation requirements provided by the manufacturer. This includes verifying the correct positioning and secure attachment of the tube to prevent any air leaks or obstructions.

Maintenance and Troubleshooting

To ensure optimal performance of the Compressor Air Inlet Tube, regular maintenance is recommended. This includes periodic inspection intervals to check for any signs of wear or damage, and cleaning procedures to remove any debris that may obstruct air flow. Common troubleshooting tips for addressing potential issues involve checking for proper installation, ensuring there are no leaks, and verifying that the tube is free from obstructions.

Performance Impact

The Compressor Air Inlet Tube affects the overall performance of the truck’s air compressor system in several ways. It influences air pressure output, system reliability, and can contribute to fuel efficiency. A well-functioning air inlet tube ensures that the compressor receives a consistent supply of air, which is vital for maintaining the required air pressure levels for the truck’s operations.

Cummins: Manufacturer Overview

Cummins Inc. is a leading manufacturer in the commercial truck industry, known for its wide range of products including engines, filtration systems, and aftermarket parts. With a strong reputation for quality and reliability, Cummins has been a trusted name among fleet operators and truck manufacturers for many years. The company’s commitment to innovation and customer satisfaction is reflected in its product offerings, including the Compressor Air Inlet Tube.

Compatibility of Compressor Air Inlet Tube (Part 5261953) with Cummins Engines

The Compressor Air Inlet Tube, identified by part number 5261953 and manufactured by Cummins, is a critical component in the air intake system of certain Cummins engines. This part ensures the efficient delivery of air to the engine’s compressor, which is essential for optimal performance and reliability.

ISB6.7 CM2250 and ISB6.7 CM2350 B101 Engines

The Compressor Air Inlet Tube (5261953) is specifically designed to fit the ISB6.7 CM2250 and ISB6.7 CM2350 B101 engines. These engines are part of Cummins’ lineup, known for their robust construction and efficiency. The fitment of this part is crucial for maintaining the integrity of the air intake system, ensuring that the engine receives the correct air-fuel mixture for combustion.

The ISB6.7 CM2250 engine is a high-performance diesel engine, widely used in various applications, including heavy-duty trucks and industrial machinery. The ISB6.7 CM2350 B101, on the other hand, is a variant of the CM2250, often equipped with additional features and enhancements to meet specific performance requirements.

Importance of Proper Fitment

Ensuring that the Compressor Air Inlet Tube (5261953) is correctly installed in these engines is vital. Proper fitment helps maintain the engine’s efficiency, reduces the risk of air leaks, and ensures that the engine operates within its designed parameters. Any discrepancies in the fitment of this part can lead to performance issues, decreased fuel efficiency, and potential engine damage over time.

Installation Considerations

When installing the Compressor Air Inlet Tube (5261953) in the ISB6.7 CM2250 and ISB6.7 CM2350 B101 engines, it is essential to follow the manufacturer’s guidelines. This includes using the correct installation procedures, ensuring all connections are secure, and verifying that the part is compatible with the specific engine model. Proper installation not only ensures the longevity of the part but also the overall health of the engine.

Role of Part 5261953 Compressor Air Inlet Tube in Engine Systems

The Compressor Air Inlet Tube, identified by part number 5261953, is integral to the efficient operation of engine systems. This component is designed to facilitate the smooth and uninterrupted flow of air into the compressor section of the engine.

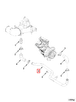

In the arrangement of engine components, the Compressor Air Inlet Tube serves as a conduit that directs ambient air from the surroundings into the compressor. This air, once compressed, plays a significant role in the combustion process within the engine. The tube’s design ensures that the air entering the compressor is free from contaminants and is at an optimal temperature and pressure, which is essential for the compressor’s performance and longevity.

The interaction between the Compressor Air Inlet Tube and the compressor is seamless. The tube is strategically positioned to align with the compressor’s intake, allowing for a direct and efficient transfer of air. This setup minimizes turbulence and pressure drops, which could otherwise lead to a decrease in compressor efficiency.

Furthermore, the Compressor Air Inlet Tube is engineered to withstand the varying conditions within the engine environment. It is constructed from materials that can endure high temperatures and pressures, ensuring durability and reliability over the engine’s operational life.

In summary, the Compressor Air Inlet Tube (part 5261953) is a key component in the engine’s air management system. Its role in directing clean, conditioned air into the compressor is fundamental to the engine’s performance, efficiency, and overall reliability.

Conclusion

The Compressor Air Inlet Tube, part number 5261953, manufactured by Cummins, is a critical component in the operation of commercial trucks and specific Cummins engines. Its role in ensuring efficient air flow into the compressor system directly impacts the performance, reliability, and fuel efficiency of the vehicle. Proper installation, maintenance, and understanding of its compatibility with specific engine models are essential for maximizing the benefits of this component.

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.