5261955

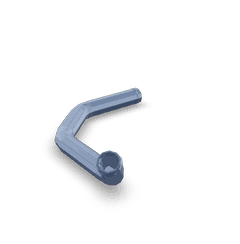

Compressor Air Inlet Tube

Cummins®

IN STOCK

1 is currently available

Ships within 1 business day

This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

The 5261955 Compressor Air Inlet Tube, manufactured by Cummins, is a component designed for use in heavy-duty truck operations. Cummins, a well-established name in the automotive industry, is known for producing reliable and high-performance parts. This particular air inlet tube is significant for maintaining the efficiency and performance of heavy-duty trucks, playing a role in the air system that supports engine function.

Basic Concepts of Compressor Air Inlet Tubes

A Compressor Air Inlet Tube is a component that facilitates the intake of air into the compressor section of a truck’s air system. Its function is to direct air efficiently into the compressor, which then pressurizes it for various applications within the vehicle, such as braking systems and suspension. The efficiency of this component directly influences the overall performance of the engine, as proper air intake is necessary for optimal combustion and power output 1.

Role of the 5261955 Compressor Air Inlet Tube in Truck Operation

The 5261955 Compressor Air Inlet Tube is integral to the operation of a truck’s air system. It works in conjunction with the compressor to ensure a steady and sufficient supply of air. This tube is designed to minimize air resistance and turbulence, which can otherwise lead to inefficiencies in air compression. By providing a smooth pathway for air intake, it helps maintain the compressor’s efficiency and, by extension, the truck’s overall performance 2.

Key Features of the 5261955 Compressor Air Inlet Tube

The 5261955 Compressor Air Inlet Tube is characterized by its robust design and construction. It is made from high-quality materials that ensure durability and resistance to the harsh conditions often encountered in heavy-duty truck operations. The tube’s design includes features that enhance air flow, such as a smooth interior surface and precise dimensions that match the compressor’s requirements. These attributes contribute to its reliable performance and longevity.

Benefits of Using the 5261955 Compressor Air Inlet Tube

Utilizing the 5261955 Compressor Air Inlet Tube offers several advantages. It provides improved air flow into the compressor, which can lead to enhanced engine efficiency. The tube’s durable construction ensures it can withstand the rigors of heavy-duty use, reducing the need for frequent replacements. Additionally, its design may contribute to more consistent air compression, potentially leading to better overall engine performance 3.

Installation and Compatibility

Proper installation of the 5261955 Compressor Air Inlet Tube is important for ensuring it functions as intended. Installation procedures should follow manufacturer guidelines to avoid issues such as leaks or improper fitment. Compatibility with various truck models and engine types is a consideration, and it is important to verify that the tube is suitable for the specific application to ensure optimal performance.

Maintenance and Troubleshooting

Regular maintenance of the 5261955 Compressor Air Inlet Tube is important for maintaining its performance. This includes checking for signs of wear or damage and ensuring that all connections are secure. Common issues may include blockages or leaks, which can be addressed by cleaning the tube or tightening connections as necessary. Following manufacturer recommendations for maintenance can help prevent more serious problems.

Performance and Efficiency

The 5261955 Compressor Air Inlet Tube contributes to the performance and efficiency of a truck’s engine by ensuring a consistent and efficient air supply to the compressor. This can lead to improvements in air compression and, consequently, engine output. Monitoring the tube’s condition and performance can provide insights into the overall health of the truck’s air system.

Cummins: A Brief Overview

Cummins Inc. is a leader in the design, manufacture, and distribution of engines, filtration, and power generation products. With a history of innovation and quality, Cummins has established a strong reputation in the automotive industry, particularly for its contributions to heavy-duty truck components. The company’s product range includes a variety of parts designed to enhance the performance, reliability, and efficiency of vehicles.

Compressor Air Inlet Tube for Cummins Engines

The Compressor Air Inlet Tube, part number 5261955, manufactured by Cummins, is a component in the air intake system of several engine models. This part is integral to ensuring efficient airflow into the engine’s compressor, which is essential for optimal engine performance.

ISB6.7 CM2250 and ISB6.7 CM2350 B101

The Compressor Air Inlet Tube is designed to fit seamlessly with the ISB6.7 CM2250 and ISB6.7 CM2350 B101 engines. These engines are known for their robust design and reliability, often used in heavy-duty applications such as construction and agricultural machinery. The part number 5261955 ensures that the air inlet tube is compatible with both engine models, providing a standardized solution for maintaining the integrity of the air intake system.

Compatibility and Installation

When installing the Compressor Air Inlet Tube, it is crucial to ensure that it is properly aligned and securely fastened to avoid any air leaks. This part is engineered to fit precisely within the engine’s design, facilitating smooth and efficient airflow. Proper installation is key to maintaining the engine’s performance and longevity.

Importance of the Compressor Air Inlet Tube

The Compressor Air Inlet Tube plays a role in the engine’s overall operation by directing clean, uncontaminated air into the compressor. This helps in preventing debris and contaminants from entering the engine, which can cause wear and reduce efficiency. By ensuring a steady and clean air supply, the Compressor Air Inlet Tube contributes to the engine’s reliability and durability.

Maintenance Considerations

Regular inspection and maintenance of the Compressor Air Inlet Tube are recommended to ensure it remains in good condition. Any signs of wear, damage, or leaks should be addressed promptly to prevent potential engine issues. Cummins provides detailed guidelines and specifications for the maintenance and replacement of this part, ensuring that it continues to perform optimally.

Role of Part 5261955 Compressor Air Inlet Tube in Engine Systems

The 5261955 Compressor Air Inlet Tube is a component in the arrangement of engine systems, specifically designed to facilitate the smooth and efficient intake of air into the compressor. This part ensures that the air entering the compressor is clean, unobstructed, and at the optimal temperature and pressure for efficient compression.

In the compressor air inlet arrangement, the 5261955 tube acts as a conduit, guiding air from the external environment into the compressor section of the engine. Its design minimizes turbulence and pressure loss, which are essential for maintaining the efficiency of the compression process. The tube is often equipped with filters and sensors to monitor the quality and quantity of the incoming air, allowing for adjustments to be made in real-time to optimize engine performance.

Furthermore, the 5261955 Compressor Air Inlet Tube is engineered to withstand the high pressures and temperatures associated with engine operation. Its material and construction are chosen to ensure durability and reliability under these demanding conditions. The tube also plays a role in reducing noise and vibration, contributing to the overall smoothness and stability of the engine’s operation.

Conclusion

The 5261955 Compressor Air Inlet Tube is a key component in the efficient functioning of engine systems, ensuring that the compressor receives the right amount of clean, pressurized air for optimal performance. Its robust design, compatibility with various engine models, and the importance of proper installation and maintenance highlight its critical role in heavy-duty truck operations.

-

Lakshminarayanan, P A, and Yogesh V Aghav. Modelling Diesel Combustion. Springer Science, 2010.

↩ -

Norman, Andrew. Diesel Technology Fundamentals Service Repair Eighth Edition. The Goodheart-Willcox Company Inc, 2016.

↩ -

Klyde, Michael, and Kirk VanGelder. Advanced Automotive Electricity and Electronics. Jones Bartlett Learning, 2010.

↩

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.