5261961

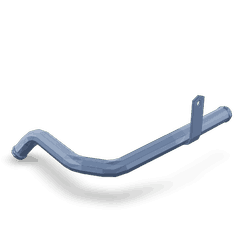

Compressor Air Inlet Tube

Cummins®

IN STOCK

3 are currently available

Ships within 1 business day

This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

The Compressor Air Inlet Tube, identified by Part #5261961, is a component manufactured by Cummins, a leading name in the commercial truck industry. This tube is integral to the air compression system in heavy-duty trucks, facilitating efficient air intake for the compressor. Cummins, known for its commitment to innovation and quality, ensures that this component meets the rigorous demands of heavy-duty applications 1.

Basic Concepts and Functionality

The Compressor Air Inlet Tube operates on the fundamental principle of directing ambient air into the compressor. This air is then compressed and stored in the air tanks, which are vital for the operation of the truck’s air brake system. The tube’s design allows for a streamlined flow of air, minimizing turbulence and ensuring that the compressor receives a consistent and clean air supply 2.

Purpose and Role in Truck Operation

In the operation of a truck, the Compressor Air Inlet Tube serves a specific function within the air compressor system. It channels air from the outside environment into the compressor, where it is pressurized. This pressurized air is crucial for the functioning of the air brakes, as well as other pneumatic systems on the truck. The efficiency of this tube directly influences the performance and reliability of the air brake system 3.

Key Features

The Compressor Air Inlet Tube is characterized by its robust design and the use of high-quality materials. It is engineered to withstand the harsh conditions typical of heavy-duty truck environments. The tube’s construction includes features that enhance its durability and performance, such as a smooth interior to reduce air resistance and external reinforcements to protect against physical damage.

Benefits

The advantages of the Compressor Air Inlet Tube include improved airflow to the compressor, which can lead to enhanced compressor efficiency. This, in turn, may contribute to better overall system performance, potentially improving fuel economy and reducing the frequency of maintenance interventions. The design of the tube also aids in minimizing the intake of contaminants, which can prolong the lifespan of the compressor 4.

Installation and Integration

Proper installation of the Compressor Air Inlet Tube is vital for its effective operation. It is designed to be compatible with a range of truck models and can be integrated into the existing air brake system with relative ease. During installation, it is important to ensure that the tube is securely fitted and aligned correctly to maintain the integrity of the air flow and the efficiency of the compressor.

Troubleshooting and Maintenance

Common issues with the Compressor Air Inlet Tube may include blockages or damage to the tube, which can impede air flow and reduce compressor efficiency. Regular inspection and cleaning of the tube can help prevent such issues. Maintenance practices should include checking for signs of wear or damage and ensuring that the tube remains free of obstructions.

Performance Enhancements

The Compressor Air Inlet Tube plays a role in enhancing the overall performance of the air compressor system. By providing a consistent and clean air supply, it contributes to the efficient operation of the compressor. This can result in improved air compressor output and increased system reliability, which are beneficial for the safe and efficient operation of the truck.

Cummins: A Brief Overview

Cummins Inc. is a global power leader that designs, manufactures, and distributes engines, filtration, and power generation products. With a history spanning over a century, Cummins has established a reputation for innovation and quality in the commercial truck industry. The company’s product range includes a variety of components and systems designed to meet the demanding requirements of heavy-duty applications, with a strong emphasis on reliability and performance.

Compatibility of 5261961 with Cummins Engines

The 5261961 Compressor Air Inlet Tube is designed to fit seamlessly with several Cummins engine models, ensuring optimal performance and reliability. This part is integral to the engine’s air intake system, facilitating the flow of air into the compressor.

ISB6.7 CM2250

The ISB6.7 CM2250 engine benefits from the precise fit and construction of the 5261961 Compressor Air Inlet Tube. This part ensures that the engine receives the correct volume and pressure of air, which is crucial for maintaining efficiency and power output.

ISB6.7 CM2350 B101

Similarly, the ISB6.7 CM2350 B101 engine is engineered to work with the 5261961 Compressor Air Inlet Tube. This component is essential for the engine’s air intake process, ensuring that the air entering the compressor is clean and at the appropriate pressure, which helps in achieving the desired performance levels.

Grouping of Engines

Both the ISB6.7 CM2250 and ISB6.7 CM2350 B101 engines share a commonality in their design and operational requirements, making the 5261961 Compressor Air Inlet Tube a versatile and compatible part across these models. This compatibility allows for easier maintenance and part replacement, providing convenience for users and technicians alike.

Role of 5261961 in Engine Systems

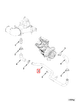

The Compressor Air Inlet Tube, identified by part number 5261961, is an integral component in the arrangement of an engine system. It is strategically positioned to facilitate the smooth and efficient flow of air into the compressor section of the engine.

This tube is integral to the compressor air inlet system, where it connects the external air source to the compressor. Its design ensures that air enters the compressor at the correct angle and velocity, optimizing the compression process. The tube’s role is to maintain a consistent airflow, which is vital for the compressor’s performance and the overall efficiency of the engine.

In the context of the engine’s arrangement, the Compressor Air Inlet Tube works in conjunction with other components such as the air filter, which cleans the incoming air, and the compressor itself, which increases the air pressure. The tube’s precise fitting and sealing are important to prevent air leaks, which could lead to a decrease in engine performance.

Furthermore, the tube’s material and construction are chosen to withstand the environmental conditions and stresses encountered in engine operation, ensuring durability and reliability in its function within the engine system.

Conclusion

The Compressor Air Inlet Tube, part number 5261961, is a critical component in the air compression system of heavy-duty trucks. Its role in ensuring a consistent and clean air supply to the compressor is vital for the efficient operation of the truck’s air brake system and other pneumatic components. The robust design and high-quality materials used in this Cummins part contribute to its durability and performance in demanding environments. Proper installation, regular maintenance, and understanding its compatibility with various Cummins engine models are key to maximizing the benefits of this component.

-

Thompson, Rob. Automotive Maintenance: Light Repair. Cengage Learning, 2019.

↩ -

Bonneau, Dominique, Aurelian Fatu, and Dominique Souchet. Internal Combustion Engine Bearings Lubrication in Hydrodynamic Bearings. Wiley-ISTE, 2014.

↩ -

Reif, Konrad. Gasoline Engine Management Systems and Components. Springer Vieweg, 2015.

↩ -

Cummins Inc. Operation and Maintenance Manual. Bulletin Number 4388775, QSB4.5 CM2250 B131.

↩

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.