This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

Introduction

The Cummins 5262754 Wiring Harness is a specialized component designed for use in commercial trucks. It serves as a part of the vehicle’s electrical system, facilitating the connection between various electrical components and the truck’s power source. This wiring harness ensures that electrical signals and power are efficiently distributed throughout the truck, supporting its operation and functionality.

Basic Concepts of Wiring Harnesses

A wiring harness is an assembly of wires, connectors, and sometimes switches and relays that transmit electrical power and signals between different parts of a vehicle. It is designed to organize and protect the wires, reducing the risk of damage and ensuring reliable performance. Within a vehicle’s electrical system, the wiring harness plays a role by providing a structured pathway for electricity to flow from the power source to the components that require it, such as lights, sensors, and control units 1.

Purpose of the Cummins 5262754 Wiring Harness

The Cummins 5262754 Wiring Harness is specifically engineered to integrate with the electrical system of commercial trucks. It connects various electrical components, ensuring they receive the necessary power and signals to function correctly. This harness is designed to work in conjunction with the truck’s engine, transmission, and other systems, providing a reliable electrical connection that supports the vehicle’s overall performance and efficiency.

Key Features

The 5262754 Wiring Harness is characterized by several key features that enhance its performance and durability. Its design includes high-quality materials that are resistant to wear, corrosion, and environmental factors. The harness is constructed with precision to ensure a secure fit and reliable connections. Additionally, it may incorporate unique attributes such as protective coatings or specialized connectors that further improve its functionality in demanding conditions.

Benefits of Using the Cummins 5262754 Wiring Harness

Utilizing the Cummins 5262754 Wiring Harness offers several advantages for truck operations. It contributes to improved reliability by ensuring stable and consistent electrical connections. This leads to enhanced efficiency, as the electrical system can operate without interruptions or failures. Moreover, the harness plays a role in safety by reducing the risk of electrical faults that could pose hazards to the vehicle and its occupants 2.

Installation Considerations

When installing the Cummins 5262754 Wiring Harness, it is important to follow guidelines and best practices to ensure a successful outcome. Preparatory steps may include inspecting the installation area for any potential issues and ensuring that all necessary tools are available. During installation, attention should be paid to securing connections properly and avoiding common pitfalls such as over-tightening connectors or damaging wires. Careful adherence to these practices will help achieve a reliable and durable installation.

Maintenance and Troubleshooting

To ensure the longevity and optimal performance of the 5262754 Wiring Harness, regular maintenance is recommended. This may involve inspecting the harness for signs of wear or damage, cleaning connections to prevent corrosion, and verifying that all components are securely connected. In the event of issues, troubleshooting steps such as checking for loose connections, testing electrical continuity, and consulting the vehicle’s manual can help identify and resolve problems effectively.

Safety Precautions

When working with the Cummins 5262754 Wiring Harness, observing important safety measures is crucial. Electrical safety practices should be followed, including disconnecting the battery before beginning any work to prevent electrical shocks. Additionally, handling guidelines for the harness and its components should be adhered to, ensuring that all tools and materials are used correctly and safely.

Cummins Overview

Cummins Inc. is a well-established company with a significant presence in the commercial truck industry. Founded in 1919, Cummins has a long history of innovation and excellence in engine and power generation technologies. The company offers a wide range of products, including engines, filtration systems, and aftermarket parts, known for their quality and reliability. Cummins’ reputation is built on a commitment to customer satisfaction and continuous improvement, making it a trusted name in the industry 3.

Compatibility

The Cummins Wiring Harness part number 5262754 is designed to be compatible with several of Cummins’ engine models. This wiring harness is a component that ensures the electrical systems of these engines function correctly. Here is a breakdown of the engines with which this wiring harness is compatible:

QSB5.9 CM850 and QSB6.7 M CM2250

The QSB5.9 CM850 and QSB6.7 M CM2250 engines are part of Cummins’ QSB series, which are known for their versatility and reliability in various applications, including industrial and agricultural use. The wiring harness 5262754 is engineered to fit these engines, ensuring that all electrical connections are properly managed and that the engine’s control systems operate smoothly.

QSC8.3 CM850 (CM2850)

The QSC8.3 CM850 (CM2850) engine is another model where the wiring harness 5262754 is applicable. This engine is typically used in heavy-duty applications, such as construction equipment and marine vessels. The harness is designed to handle the higher electrical demands of this engine, providing a robust and reliable connection for all electrical components.

QSM11 CM570

The QSM11 CM570 engine is part of Cummins’ QSM series, which is known for its high power output and efficiency. The wiring harness 5262754 is compatible with this engine, ensuring that all electrical systems are properly connected and that the engine can perform at its best. This engine is often used in heavy-duty applications, such as mining and transportation.

By ensuring compatibility with these specific engine models, the wiring harness 5262754 provides a seamless integration with the electrical systems of these engines, facilitating efficient and reliable operation.

Role of the 5262754 Wiring Harness in Engine Systems

The 5262754 Wiring Harness is integral to the electrical infrastructure of engine systems, facilitating seamless communication and power distribution among various components.

Connection

The wiring harness establishes vital electrical connections within the engine system. It links the engine control unit (ECU) to sensors and actuators, ensuring that data is accurately transmitted and received. This connectivity allows for precise monitoring and adjustment of engine parameters, enhancing overall performance and efficiency.

Exhaust Outlet

In the context of the exhaust outlet, the wiring harness plays a significant role in managing the exhaust gas recirculation (EGR) system. It provides the necessary electrical pathways for the EGR valve, allowing it to open and close as required. This helps in reducing emissions and improving fuel efficiency by recirculating a portion of the exhaust gases back into the intake manifold.

Exhaust Transfer Assembly

For the exhaust transfer assembly, the wiring harness ensures that all electronic components, such as sensors and solenoids, are properly powered and communicate effectively. It supports the operation of oxygen sensors, which monitor the exhaust gases to provide feedback to the ECU. This feedback loop is essential for maintaining optimal air-fuel ratios and ensuring that the catalytic converter functions efficiently.

Conclusion

The Cummins 5262754 Wiring Harness is a critical component in the electrical systems of commercial trucks, ensuring reliable and efficient operation. Its design, featuring high-quality materials and precise construction, supports the integration of various electrical components within the vehicle. Regular maintenance and adherence to safety precautions are essential for the longevity and optimal performance of this part. By understanding its role and benefits, truck operators and maintenance personnel can ensure the smooth and safe operation of their vehicles.

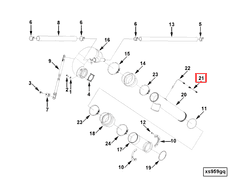

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.