This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

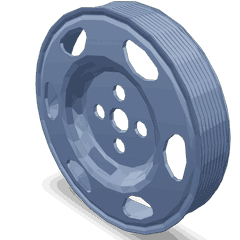

The Crankshaft Pulley 5263196 by Cummins is a component designed for use in commercial trucks. It serves a significant role in the operation of these vehicles by facilitating the transfer of power from the engine to various accessories. Understanding its purpose and functionality is key to maintaining the efficiency and reliability of truck engines.

Basic Concepts of Crankshaft Pulleys

A crankshaft pulley, also known as a harmonic balancer, is a toothed wheel attached to the front of an engine’s crankshaft. Its primary function is to drive the serpentine belt, which in turn powers engine accessories such as the alternator, water pump, and air conditioning compressor. The pulley ensures that these components receive the necessary power to operate, while also helping to reduce vibrations produced by the engine 1.

Purpose of the 5263196 Crankshaft Pulley

This part is integral to the operation of a truck’s engine. It plays a role in driving engine accessories by transferring rotational force from the crankshaft to the serpentine belt. Additionally, it maintains proper belt tension, which is crucial for the efficient operation of driven accessories and the prevention of belt slippage.

Key Features

The 5263196 is characterized by its robust design and the use of high-quality materials. It features a durable construction that enhances its performance and longevity. The pulley is engineered to withstand the demanding conditions of commercial truck engines, ensuring reliable operation over time.

Benefits

The use of this Cummins part offers several advantages. It contributes to improved engine efficiency by ensuring that accessories receive consistent power. This results in reduced wear on driven accessories, leading to enhanced overall performance of the truck. The pulley’s design also helps in minimizing engine vibrations, contributing to a smoother operation 2.

Installation and Compatibility

Proper installation of this part is crucial for its effective operation. It is designed to be compatible with specific Cummins engines, ensuring a precise fit and function. During installation, it is important to follow manufacturer guidelines to ensure that the pulley is correctly aligned and secured, which is vital for maintaining the integrity of the engine’s accessory drive system.

Troubleshooting and Maintenance

Common issues with the 5263196 may include belt slippage or pulley misalignment. Regular inspection and maintenance are recommended to address these issues promptly. This includes checking for signs of wear or damage, ensuring proper belt tension, and verifying the alignment of the pulley. Adhering to a maintenance schedule can help in identifying potential problems early, ensuring the longevity and performance of the pulley.

Cummins Overview

Cummins Inc. is a global power leader that designs, manufactures, and distributes a wide range of power solutions. With a strong reputation in the industry, Cummins is committed to producing high-quality components that meet the demanding requirements of commercial vehicles. The company’s focus on innovation and quality ensures that its products, including the 5263196, deliver reliable performance and durability 3.

Compatibility

This part is designed to fit seamlessly with a range of Cummins engines, ensuring optimal performance and reliability. It is engineered to work with the following engine models:

4B3.9 Engines

The 5263196 is specifically tailored for the 4B3.9 engine series. This engine is known for its robust design and efficiency, making it a popular choice in various applications. The pulley’s precise fit ensures that it can effectively engage with the crankshaft, facilitating smooth engine operation and reducing the risk of wear and tear.

6B5.9 Engines

Similarly, the 5263196 is compatible with the 6B5.9 engine series. This engine is recognized for its power and durability, often used in heavy-duty applications. The pulley’s design allows for a secure and reliable connection with the crankshaft, ensuring that the engine runs smoothly and efficiently.

Grouping of Engines

Both the 4B3.9 and 6B5.9 engines benefit from the use of the 5263196 due to its universal design features. This compatibility allows for easier maintenance and replacement, as the same part can be used across different engine models within the specified series. This not only simplifies inventory management but also ensures that the correct part is used, maintaining the engine’s performance standards.

Role of Part 5263196 Crankshaft Pulley in Engine Systems

The 5263196 is an integral component in the efficient operation of various engine systems. It is primarily responsible for transmitting rotational force from the crankshaft to other engine components, ensuring smooth and synchronized operation.

Interaction with the Adapter

The crankshaft pulley interfaces with the adapter, which is a crucial intermediary component. This adapter facilitates the connection between the pulley and the crankshaft, ensuring a secure and precise fit. The adapter’s role is to maintain alignment and absorb any minor misalignments that may occur during engine operation, thereby enhancing the overall efficiency and longevity of the crankshaft pulley.

Front Drive Mechanism

In engines equipped with front-wheel drive systems, the crankshaft pulley plays a significant role. It drives the front drive mechanism by transferring rotational energy from the crankshaft. This energy transfer is essential for the front wheels to receive the necessary power for propulsion. The pulley’s design ensures that this transfer is smooth, minimizing energy loss and maximizing drive efficiency.

Integration with the Damper

The crankshaft pulley often incorporates a damper, which is designed to reduce vibrations and smooth out the power delivery from the engine. The damper absorbs the irregular pulses of power generated by the engine’s combustion cycles, converting them into a more consistent rotational force. This results in a smoother operation of the engine and reduces wear on connected components.

Vibration Management

One of the key functions of the crankshaft pulley is vibration management. By working in conjunction with the damper, the pulley helps to mitigate the vibrations produced by the engine. This is particularly important in high-performance engines where the forces generated are significantly greater. Effective vibration management not only enhances the durability of the engine components but also contributes to a more comfortable driving experience.

Conclusion

The 5263196 Crankshaft Pulley is a vital component that ensures the efficient and smooth operation of various engine systems. Its interactions with the adapter, front drive mechanism, damper, and its role in vibration management underscore its importance in maintaining engine performance and reliability.

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.