This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

Introduction

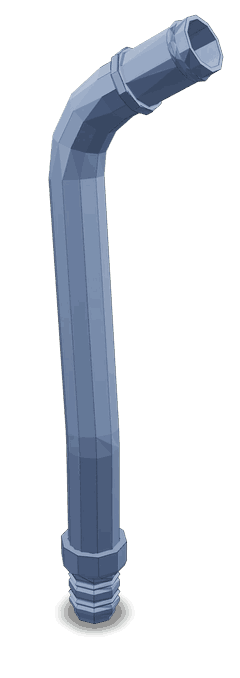

The Cummins 5264726 Tur Oil Drain Tube is a component designed for use in heavy-duty trucks. Its primary function is to facilitate the drainage of oil from the engine, playing a significant role in the routine maintenance of these vehicles. Proper oil drainage is vital for maintaining engine health and ensuring optimal performance 1.

Function and Operation

The Tur Oil Drain Tube operates as part of the truck’s engine system by providing a pathway for oil to exit the engine during maintenance procedures. This component is integral to the oil change process, allowing for efficient and clean oil removal. By ensuring that old oil is effectively drained, the tube helps in maintaining the engine’s lubrication system, which is crucial for reducing wear and tear on engine components 2.

Key Features

The design and construction of the Tur Oil Drain Tube are tailored to meet the demanding requirements of heavy-duty truck engines. It is made from durable materials that can withstand high temperatures and pressures. The tube’s build quality ensures longevity and reliability, with a focus on preventing leaks and ensuring a secure fit within the engine system. Unique attributes of the tube may include a threaded connection for a secure seal and a robust construction that resists corrosion.

Benefits of Using the Tur Oil Drain Tube

Incorporating the Tur Oil Drain Tube into a truck’s maintenance routine offers several advantages. It contributes to improved engine efficiency by ensuring that oil changes are conducted thoroughly, removing all old oil and contaminants. This process helps in maintaining the engine’s performance and longevity. Additionally, the tube’s design can reduce maintenance time by facilitating a quicker and more efficient oil drainage process. Enhanced overall performance of the truck is a direct result of well-maintained engine lubrication 3.

Installation Process

Installing the Tur Oil Drain Tube requires attention to detail to ensure optimal functionality. The process involves locating the oil drain plug on the engine, removing the old drain plug (if applicable), and threading the tube into place. It is important to follow the manufacturer’s guidelines for torque specifications to ensure a secure fit without over-tightening, which could damage the thread or the tube itself. Proper installation is key to preventing oil leaks and ensuring the tube functions as intended.

Maintenance and Troubleshooting

To maintain the Tur Oil Drain Tube, regular inspections for signs of wear, corrosion, or damage are recommended. Cleaning the tube and its connection points before and after use can prevent buildup and ensure a secure seal. Common issues may include leaks, which can often be addressed by re-tightening the tube or replacing damaged components. Troubleshooting should involve checking for proper installation and ensuring that all connections are secure.

Cummins: A Brief Overview

Cummins Inc. is a global power leader that designs, manufactures, and distributes engines, filtration, and power generation products. With a history spanning over a century, Cummins has established a reputation for quality and reliability in the automotive industry. The company’s product offerings include a wide range of engines and components designed for heavy-duty applications, underscoring the quality and dependability of the Tur Oil Drain Tube.

Compatibility with Cummins Engines

The Tur Oil Drain Tube part number 5264726, manufactured by Cummins, is designed to fit seamlessly within the engine systems of the QSC9 CM2250/QSL9 CM2250, QSL9 CM2250, and QSL9 CM2350 L102 engines. This part is integral to the maintenance and operational efficiency of these engines, ensuring that oil is properly drained from the turbocharger system. Its compatibility across these engine models underscores its versatility and importance in maintaining the integrity of the engine’s lubrication system.

Role of the Tur Oil Drain Tube in Engine Systems

The Tur Oil Drain Tube is an essential component in the management and maintenance of oil within the turbocharger system of an engine. This tube is specifically designed to facilitate the drainage of oil from the turbocharger, ensuring that excess oil does not accumulate within the system.

In the context of turbocharger plumbing, the Tur Oil Drain Tube plays a significant role. It is integrated into the oil return system, allowing oil that has been used to lubricate the turbocharger’s bearings and other moving parts to be efficiently drained back into the engine’s oil sump. This process is vital for maintaining the proper oil level within the turbocharger and preventing oil starvation, which could lead to increased wear and potential failure of the turbocharger components.

Furthermore, the Tur Oil Drain Tube is connected to the plumbing system of the engine, which includes various hoses, pipes, and fittings that transport fluids throughout the engine. This connection ensures that the drained oil is correctly routed back to the sump, where it can be recirculated and reused. The efficient drainage provided by the Tur Oil Drain Tube helps in maintaining the overall health and performance of the turbocharger and the engine system as a whole.

Conclusion

The Cummins 5264726 Tur Oil Drain Tube is a critical component for maintaining the health and efficiency of heavy-duty truck engines. Its role in facilitating proper oil drainage from the turbocharger system ensures that engines operate at optimal performance levels. Regular maintenance and proper installation of this part are essential for preventing leaks and ensuring the longevity of the engine components.

-

Taghavifar, H., & Mardani, A. (2017). Offroad Vehicle Dynamics Analysis Modelling and Optimization. Springer.

↩ -

Zhan, Q., Eben, S., & Deng, L. K. (2018). Automotive Heating Ventilation and Air Conditioning. Jones Bartlett Learning.

↩ -

Wright, G. (2015). Fundamentals of Medium-Heavy Duty Diesel Engines. Jones & Bartlett Learning.

↩

SPECIFICATIONS

BILL OF MATERIALS

| Name | Quantity | Part Number |

|---|---|---|

| O Ring Seal | 2 | 3928624 |

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.