5265832

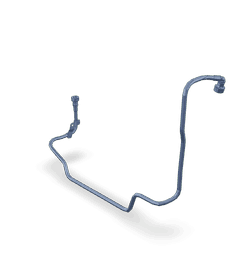

Compressor Water Outlet Tube

Cummins®

IN STOCK

2 are currently available

Ships within 1 business day

This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

The Compressor Water Outlet Tube, identified by part number 5265832, is a component manufactured by Cummins, a leader in the production of diesel engines and related technologies. This tube is integral to the cooling system of heavy-duty truck engines, facilitating the efficient circulation of coolant. Its role within the engine system is to ensure that the engine operates within optimal temperature ranges, thereby contributing to the overall performance and longevity of the engine 1.

Function and Operation

The Compressor Water Outlet Tube operates as a conduit within the engine cooling system, allowing coolant to flow from the compressor to other parts of the engine. As the engine operates, it generates heat, which is absorbed by the coolant. The tube directs this heated coolant away from the compressor, ensuring that the temperature remains within safe limits. This process involves the coolant interacting with various engine components, absorbing heat, and then being circulated back through the system to be cooled again 2.

Purpose of the Compressor Water Outlet Tube

The specific role of the Compressor Water Outlet Tube is to aid in the regulation of engine temperature. By efficiently routing coolant away from the compressor, it helps maintain an optimal operating temperature. This not only enhances the engine’s efficiency but also contributes to its durability by preventing overheating, which can lead to engine damage.

Key Features

The Compressor Water Outlet Tube is designed with several key features that enhance its performance and durability. It is typically made from high-quality materials that are resistant to corrosion and high temperatures. The design of the tube ensures a secure fit within the engine system, minimizing the risk of leaks. Additionally, it may include specific design elements that improve the flow of coolant, such as smooth internal surfaces and precise fittings.

Benefits

Utilizing the Compressor Water Outlet Tube in heavy-duty truck engines offers several benefits. It contributes to improved engine performance by ensuring that the engine operates at optimal temperatures. This can lead to enhanced fuel efficiency and reduced wear on engine components. Furthermore, the durable construction of the tube ensures long-term reliability, reducing the need for frequent replacements and maintenance.

Installation and Compatibility

Proper installation of the Compressor Water Outlet Tube is crucial for its effective operation. It is designed to be compatible with various Cummins engine models, ensuring a seamless integration into the engine cooling system. Installation guidelines typically include ensuring a secure fit and proper alignment with other components to prevent leaks and ensure efficient coolant flow.

Maintenance and Troubleshooting

Regular maintenance of the Compressor Water Outlet Tube is important to ensure its longevity and efficiency. This may include periodic inspections for signs of wear or damage, such as cracks or leaks. Common issues that may arise include blockages within the tube, which can impede coolant flow. Troubleshooting tips may involve cleaning the tube or, in more severe cases, replacing it to restore optimal engine cooling.

Cummins: A Brief Overview

Cummins Inc. is a global power leader that designs, manufactures, and distributes engines, filtration, and power generation products. With a history spanning over a century, Cummins has established a reputation for quality and innovation in the automotive industry. The company’s commitment to excellence is evident in its wide range of products, which are designed to meet the demanding requirements of heavy-duty applications. Cummins’ focus on quality and innovation ensures that its components, including the Compressor Water Outlet Tube, are reliable and efficient, contributing to the performance and durability of engines in which they are installed.

Compatibility with Cummins Engines

The Compressor Water Outlet Tube, identified by part number 5265832, is a critical component in the cooling system of certain Cummins engines. This part is designed to manage the flow of coolant from the compressor section, ensuring efficient heat dissipation and maintaining optimal engine performance.

Compatibility with ISC8.3 CM2250 and ISL9 CM2250 Engines

The Compressor Water Outlet Tube (5265832) is specifically engineered to fit the ISC8.3 CM2250 and ISL9 CM2250 engines. These engines are part of the Cummins lineup, known for their robust performance and reliability in various industrial applications.

ISC8.3 CM2250 Engine:

- The ISC8.3 CM2250 engine is a high-performance model, often utilized in heavy-duty applications such as construction equipment and agricultural machinery.

- The Compressor Water Outlet Tube ensures that the coolant is effectively channeled away from the compressor, preventing overheating and maintaining the engine’s efficiency.

ISL9 CM2250 Engine:

- The ISL9 CM2250 engine is another high-capacity model within the Cummins range, frequently used in on-highway and vocational applications.

- This engine benefits from the precise design of the Compressor Water Outlet Tube, which aids in the efficient management of coolant flow, contributing to the engine’s longevity and reliability.

Both engines rely on the Compressor Water Outlet Tube to maintain optimal operating temperatures, ensuring that the compressor section does not overheat. This part is integral to the cooling system, providing a seamless connection between the compressor and the coolant pathways, thereby enhancing the overall performance and durability of the engines.

Role of 5265832 Compressor Water Outlet Tube in Engine Systems

The 5265832 Compressor Water Outlet Tube is an essential component in the arrangement of various engine systems, particularly those involving the compressor and its coolant system. This tube facilitates the efficient transfer of coolant from the compressor, ensuring that the compressor operates within optimal temperature ranges.

In the context of the compressor coolant system, the 5265832 tube acts as a conduit for the coolant as it exits the compressor. This is vital for maintaining the compressor’s performance and longevity, as excessive heat can lead to decreased efficiency and potential damage. The tube is designed to handle the pressure and temperature of the coolant, ensuring a reliable flow that contributes to the overall stability of the engine’s cooling system.

Moreover, the integration of the 5265832 tube within the engine’s air system is noteworthy. As the compressor works to pressurize air for combustion, the heat generated must be managed effectively. The tube plays a part in this management by allowing the coolant to absorb excess heat from the compressor, which is then circulated away to be cooled before returning to the system. This interplay between the air and coolant systems underscores the importance of the 5265832 tube in maintaining a balanced operating environment for the engine.

The design and placement of the 5265832 Compressor Water Outlet Tube are tailored to the specific requirements of the engine it serves. It is positioned to ensure that the coolant flow is uninterrupted and that the tube itself is protected from the high-pressure air streams within the engine. This careful consideration in the tube’s arrangement is a testament to the engineering precision that goes into crafting such components, ensuring they contribute effectively to the engine’s performance and durability.

Conclusion

The Compressor Water Outlet Tube, part number 5265832, plays a significant role in the cooling systems of heavy-duty truck engines, particularly those manufactured by Cummins. Its design and function are critical for maintaining optimal engine temperatures, ensuring efficient operation, and contributing to the longevity of the engine. Proper installation, regular maintenance, and understanding its compatibility with specific engine models are essential for maximizing the benefits of this Cummins part.

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.