5265912

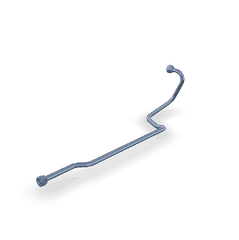

Compressor Water Inlet Tube

Cummins®

IN STOCK

More than 10 are currently available

Ships within 1 business day

This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

Introduction

The Compressor Water Inlet Tube, identified by part number 5265912, is a component manufactured by Cummins, a well-established name in the automotive industry. This tube is integral to the operation of heavy-duty truck engines, facilitating the efficient management of water flow within the engine’s cooling system 3. Cummins is renowned for producing high-quality engine components, and the Compressor Water Inlet Tube is no exception, designed to enhance engine performance and reliability.

Basic Concepts and Functionality

The Compressor Water Inlet Tube operates on the fundamental principle of directing water into the compressor section of the engine. This process is vital for cooling the compressed air before it enters the engine’s combustion chamber 4. By maintaining the optimal temperature of the compressed air, the tube contributes to the engine’s overall efficiency and performance. Its design allows for a steady and controlled flow of water, ensuring that the cooling process is both effective and consistent.

Purpose and Role in Truck Operation

In the operation of a truck, the Compressor Water Inlet Tube serves a specific function that is crucial for engine efficiency and durability. It ensures that the compressed air entering the engine is at the correct temperature, which is vital for the combustion process 1. This not only enhances the engine’s performance but also contributes to its longevity by preventing overheating and potential damage.

Key Features

The Compressor Water Inlet Tube is characterized by several design elements that enhance its performance and reliability. These include a robust construction that can withstand high pressure and temperature, precise engineering to ensure optimal water flow, and compatibility with Cummins engines, ensuring seamless integration and operation.

Benefits

The advantages provided by the Compressor Water Inlet Tube are significant. It plays a role in the engine cooling system by ensuring that the compressed air is adequately cooled before entering the combustion chamber. This leads to improved engine efficiency, as the combustion process is more effective at optimal temperatures 2. Additionally, the tube contributes to the prolonged lifespan of engine components by preventing overheating, which can cause premature wear and failure.

Installation and Integration

Proper installation of the Compressor Water Inlet Tube is vital for ensuring its optimal functionality. The installation process involves securing the tube within the engine system, ensuring that it is correctly aligned and connected to the water supply and compressor. It is important to follow manufacturer guidelines to ensure that the tube is installed in a manner that allows for efficient water flow and effective cooling.

Common Issues and Troubleshooting

Typical problems associated with the Compressor Water Inlet Tube may include leaks, blockages, or damage to the tube. These issues can be identified through regular inspections and monitoring of the engine’s performance. Troubleshooting methods may involve checking for signs of wear or damage, ensuring that connections are secure, and verifying that water flow is consistent and unobstructed.

Maintenance Practices

Routine maintenance procedures are vital for upholding the performance and longevity of the Compressor Water Inlet Tube. This includes regular inspections for signs of wear or damage, cleaning to remove any buildup that may obstruct water flow, and replacement according to manufacturer guidelines or when signs of failure are detected. Adhering to these maintenance practices ensures that the tube continues to operate efficiently and contributes to the overall performance of the engine.

Cummins Overview

Cummins Inc. is a global power leader that designs, manufactures, and distributes engines, filtration, and power generation products. With a history spanning over a century, Cummins has established a reputation for producing high-quality, reliable engine components. The company’s product range includes a variety of engine components designed for heavy-duty applications, and the Compressor Water Inlet Tube is a testament to Cummins’ commitment to quality and performance in the automotive industry.

Compatibility with Cummins Engines

The Compressor Water Inlet Tube, part number 5265912, is designed to fit seamlessly with several Cummins engine models, including the ISC8.3 CM2250, ISL9 CM2250, and QSL9 CM2250 engines. This part is integral to the cooling system of these engines, ensuring efficient heat dissipation and maintaining optimal operating temperatures. The design of this Cummins part is standardized to ensure compatibility and ease of installation, crafted from high-quality materials that can withstand the rigors of engine operation 3.

Role in Engine Systems

This part is an essential component in the arrangement of the engine’s cooling system, specifically designed to facilitate the efficient operation of the compressor coolant system. It serves as a conduit for the coolant to enter the compressor, ensuring a steady and regulated flow of coolant into the compressor, which is vital for maintaining optimal operating temperatures 4. The design and placement of the Compressor Water Inlet Tube are meticulously engineered to ensure that the coolant reaches all necessary areas within the compressor, enhancing the cooling efficiency and reliability of the entire system.

Conclusion

The Compressor Water Inlet Tube (part number 5265912) by Cummins plays a significant role in the efficient operation and longevity of heavy-duty truck engines. Its design and functionality are crucial for maintaining optimal engine performance and reliability, making it a vital component in the engine’s cooling system.

-

Frank Sander, Diesel Mechanics, First Edition, Global Media, 2007.

↩ -

George Peters, Barbara J Peters, Automobile Vehicle Safety, CRC Press, 2002.

↩ -

Harald Naunheimer, Bernd Bertsche, Joachim Ryborz, Wolfgang Novak, Automotive Transmissions Fundamentals Selection Design and Application, Springer Vieweg, 2011.

↩ ↩ -

P. A. Lakshminarayanan, Avinash Kumar Agarwal, Design and Development of Heavy Duty Diesel Engines: A Handbook, Springer, 2019.

↩ ↩

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.