This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

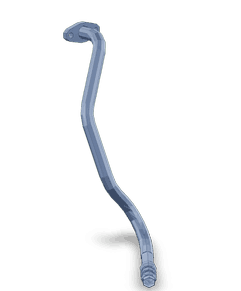

The Tur Oil Drain Tube, part number 5270272, manufactured by Cummins, is a critical component designed for the maintenance and operation of heavy-duty trucks. Cummins, a reputable name in the automotive and heavy-duty truck industries, ensures that this part meets the rigorous demands of commercial vehicle applications. The Tur Oil Drain Tube is integral to the efficient functioning of the turbocharger and, by extension, the engine.

Basic Concepts and Functionality

The Tur Oil Drain Tube operates based on principles of fluid dynamics and mechanical engineering. Its design allows for the controlled drainage of used oil from the turbocharger. This tube is a vital component within the truck’s lubrication system, ensuring that oil is efficiently circulated and drained, thereby maintaining optimal turbocharger performance.

Purpose and Role in Truck Operation

The primary role of the Tur Oil Drain Tube is to facilitate the draining of used oil from the turbocharger. This process is essential for maintaining the efficiency and longevity of both the turbocharger and the engine. By ensuring that old oil is regularly removed, the tube helps prevent the buildup of contaminants that can lead to decreased performance and potential damage.

Key Features

The Tur Oil Drain Tube is characterized by several key features that enhance its functionality and durability. These include a robust construction that can withstand the high pressures and temperatures within the turbocharger system, precise engineering that ensures a perfect fit and efficient operation, and compatibility with specific turbocharger models, ensuring seamless integration into the truck’s system.

Benefits

Incorporating the Tur Oil Drain Tube into a heavy-duty truck’s maintenance regimen offers several benefits. These include improved turbocharger performance due to the regular removal of used oil, enhanced engine reliability as a result of reduced wear and contamination, and simplified maintenance procedures, making it easier for technicians to perform necessary checks and replacements.

Installation Process

Installing the Tur Oil Drain Tube requires careful attention to detail to ensure optimal performance and longevity. The process involves several steps, including preparing the turbocharger for tube installation, securing the tube in place using the appropriate tools, and conducting a series of checks to confirm that the installation is correct and secure. Following best practices during installation is crucial for the tube’s effective operation.

Maintenance and Care

Regular maintenance and care of the Tur Oil Drain Tube are essential for its continued efficient operation. This includes routine inspections to check for signs of wear or damage, cleaning the tube and surrounding areas to prevent blockages, and replacing the tube if any issues are detected. Adhering to recommended maintenance schedules helps ensure the turbocharger and engine remain in top condition.

Troubleshooting Common Issues

Common issues associated with the Tur Oil Drain Tube may include leaks, blockages, or malfunctions. Identifying these problems early is key to preventing more serious issues. Solutions may involve tightening connections, cleaning out blockages, or, in some cases, replacing the tube. Preventive measures, such as regular maintenance checks, can help avoid these common problems.

Cummins: A Brief Overview

Cummins Inc. is a leader in the automotive and heavy-duty truck industries, known for its commitment to quality, innovation, and customer satisfaction. With a rich history of providing reliable and high-performance products, Cummins has established a reputation for excellence. Its product offerings span a wide range of engines, filtration systems, and aftermarket parts, all designed to meet the demanding needs of commercial vehicle applications 1.

Role of Part 5270272 Tur Oil Drain Tube in Engine Systems

The Tur Oil Drain Tube, part number 5270272, is an essential component in the efficient operation of engine systems, particularly in relation to the turbocharger and its associated plumbing. This tube facilitates the drainage of oil from the turbocharger, ensuring that excess oil does not accumulate within the system.

In the context of turbocharger plumbing, the Tur Oil Drain Tube is integrated into the oil return system. It connects to the turbocharger’s oil feed line and the oil return line, creating a pathway for used oil to be efficiently routed back to the engine’s oil sump. This process is vital for maintaining the turbocharger’s lubrication system, which is necessary for its optimal performance and longevity 2.

The turbocharger relies on a consistent supply of oil for lubrication of its bearings and other moving parts. As the turbocharger operates, it generates heat, which can cause the oil to thin and become less effective. The Tur Oil Drain Tube helps manage this by allowing the heated oil to drain away, ensuring that fresher, cooler oil is circulated through the system. This not only enhances the turbocharger’s efficiency but also contributes to its durability by preventing overheating and excessive wear 3.

Conclusion

In summary, the Tur Oil Drain Tube, part number 5270272, plays a significant role in the turbocharger’s oil management system. By facilitating the drainage of used oil, it supports the turbocharger’s lubrication needs, contributes to its efficient operation, and aids in its overall maintenance within the engine system.

-

Mananathan, R. (2022). Automobile Wheel Alignment and Wheel Balancing. SAE International.

↩ -

Klyde, M., & VanGelder, K. (2010). Advanced Automotive Electricity and Electronics. Jones Bartlett Learning.

↩ -

Huzij, R., Spano, A., & Bennett, S. (2014). Modern Diesel Technology Heavy Equipment Systems. Delmar Cengage Learning.

↩

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.