This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

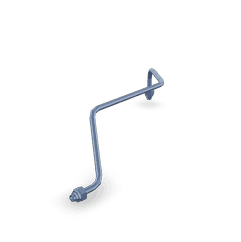

The Compressor Water Inlet Tube, identified by part number 5273614, is a component manufactured by Cummins, a leading name in the automotive and heavy-duty truck industry. This tube is integral to the operation of heavy-duty truck engines, facilitating efficient cooling processes that contribute to overall engine performance and longevity 1.

Function and Operation

This part operates within the engine system by directing coolant into the compressor. This process is vital for maintaining optimal operating temperatures, as the coolant absorbs heat from the compressor, which is a high-stress component within the engine. The tube interacts with the engine’s cooling system, ensuring a steady flow of coolant that helps in dissipating heat effectively 2.

Purpose of the Compressor Water Inlet Tube

The specific role of the Compressor Water Inlet Tube in a truck’s operation is to enhance engine efficiency and performance. By ensuring that the compressor remains at an optimal temperature, the tube helps prevent overheating, which can lead to reduced engine efficiency and potential damage. This component contributes to maintaining the engine’s performance under various operating conditions 3.

Key Features

The Compressor Water Inlet Tube is designed with several key features that enhance its functionality. It is typically made from durable materials that can withstand the high temperatures and pressures within the engine system. The design of the tube includes precise fittings and connections that ensure a secure and leak-free integration into the engine’s cooling system. Additionally, the tube may feature reinforced sections to handle the dynamic stresses it encounters during operation.

Benefits

The advantages provided by the Compressor Water Inlet Tube include improved engine cooling, which is crucial for maintaining engine efficiency and preventing overheating. Its durable construction contributes to increased longevity, reducing the frequency of replacements and associated costs. For fleet operators, this can translate into potential cost savings over time, as well as reduced downtime due to component failure.

Installation and Integration

Proper installation of the Compressor Water Inlet Tube is critical for ensuring its effective operation within the engine system. It is designed to be compatible with various Cummins engine models, facilitating seamless integration. Installation guidelines typically include steps to ensure that the tube is correctly aligned and securely fastened, with all connections properly sealed to prevent leaks.

Maintenance and Care

Routine maintenance practices are recommended to prolong the lifespan of the Compressor Water Inlet Tube. These may include regular inspections for signs of wear or damage, ensuring that all connections remain tight and leak-free, and cleaning the tube as necessary to remove any buildup that could impede coolant flow. Adhering to these maintenance practices can help maintain the tube’s efficiency and reliability.

Troubleshooting Common Issues

Frequent problems associated with the Compressor Water Inlet Tube may include leaks, blockages, or damage to the tube itself. Diagnostic steps to identify these issues can involve visual inspections, checking for coolant leaks, and assessing the tube’s condition. Repair or replacement procedures should follow manufacturer guidelines to ensure that the tube is restored to its optimal operating condition.

Cummins: A Brief Overview

Cummins Inc. is a global power leader that designs, manufactures, and distributes engines, filtration, and power generation products. With a history spanning over a century, Cummins has established a reputation for quality, reliability, and innovation in the automotive and heavy-duty truck industry. The company’s product range includes a variety of engines and components designed to meet the demanding requirements of commercial vehicles and industrial applications.

Cummins Compressor Water Inlet Tube (Part 5273614) Compatibility

The Cummins Compressor Water Inlet Tube, identified by part number 5273614, is a critical component in the cooling system of certain engine models. This part is designed to facilitate the flow of water into the engine’s compressor, ensuring efficient cooling and optimal performance. It is engineered to withstand the rigors of engine operation, providing durability and reliability.

Engine Compatibility

The Compressor Water Inlet Tube (5273614) is compatible with the following Cummins engine models:

- 4B3.9: This engine model benefits from the precise engineering of the part 5273614, ensuring that the water inlet system operates smoothly and effectively.

The part is meticulously designed to fit seamlessly into the cooling system architecture of these engines, ensuring that water is directed to the compressor in a controlled and efficient manner. This compatibility is crucial for maintaining the engine’s performance and longevity.

Grouping of Engines

For ease of reference, the engines that are compatible with the Compressor Water Inlet Tube (5273614) can be grouped as follows:

- 4B3.9: This grouping includes engines that share similar design and operational characteristics, making the part 5273614 a suitable fit for all engines within this group.

By ensuring that the Compressor Water Inlet Tube is correctly installed and functioning, engine operators can maintain the integrity of their cooling systems and prevent potential overheating issues.

Role of Part 5273614 Compressor Water Inlet Tube in Engine Systems

The part 5273614 Compressor Water Inlet Tube is an essential component in the arrangement of engine systems, specifically within the compressor coolant circuit. This tube facilitates the introduction of coolant into the compressor, ensuring that the compressor operates within optimal temperature ranges.

In the compressor coolant arrangement, the inlet tube is positioned to direct coolant flow towards the compressor’s heat exchange surfaces. This ensures efficient heat dissipation from the compressed air, which is vital for maintaining compressor efficiency and longevity. The tube’s design allows for a consistent coolant flow, which is necessary for stable compressor performance under varying operational conditions.

Furthermore, the integration of the Compressor Water Inlet Tube within the engine system enhances the overall thermal management of the engine. By effectively cooling the compressor, the tube contributes to the prevention of thermal stress and potential damage to compressor components. This, in turn, supports the engine’s reliability and performance.

The tube also plays a role in the maintenance of the compressor coolant system. Its design allows for easy access during routine inspections and maintenance procedures, facilitating the detection of potential issues such as leaks or blockages. This proactive approach to maintenance helps in preserving the integrity of the compressor coolant system and ensures continued efficient operation of the engine.

Conclusion

The Compressor Water Inlet Tube (5273614) is a vital component in the cooling system of Cummins engines, ensuring efficient operation and longevity of the compressor. Its durable design, compatibility with various engine models, and role in thermal management make it an essential part of engine systems. Proper installation, maintenance, and troubleshooting are key to maximizing the benefits of this part.

-

Huzij, R., Spano, A., & Bennett, S. (2019). Modern Diesel Technology: Heavy Equipment Systems. Cengage Learning.

↩ -

Brach, R. M. (2023). SAE International’s Dictionary of Vehicle Accident Reconstruction and Automotive Safety. SAE Books.

↩ -

Cummins Inc. (n.d.). ISB6.7 CM2350 B101 Service Manual (2883567). Cummins Inc.

↩

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.