This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

The Cummins 5282929 Vibration Isolator is a component designed to mitigate the transmission of vibrations from the engine to the truck’s frame. Its role is significant in the operation of commercial trucks, contributing to a smoother ride, reduced wear on components, and potentially improved fuel efficiency 1.

Basic Concepts of Vibration Isolators

Vibration isolators are devices used in mechanical systems to reduce the transmission of vibrations from a source to its surroundings. They function by absorbing or dampening the vibrations, thereby minimizing their impact on connected components. In the context of commercial trucks, vibration isolators play a role in enhancing ride comfort and protecting sensitive components from the adverse effects of engine vibrations 2.

Purpose of the Cummins 5282929 Vibration Isolator

The Cummins 5282929 Vibration Isolator is designed to reduce the vibrations transmitted from the engine to the truck’s frame. By doing so, it contributes to a more stable and comfortable ride for the occupants and helps in minimizing the wear and tear on various truck components. This isolator plays a role in enhancing the overall performance and longevity of the truck by ensuring that the engine’s vibrations do not adversely affect other parts of the vehicle 3.

Key Features

The Cummins 5282929 Vibration Isolator features a design that includes high-quality materials and engineering to effectively absorb and dampen vibrations. Its construction may involve rubber or elastomeric materials, which are chosen for their ability to flex and absorb shock. The design elements of this isolator are tailored to fit specific applications, ensuring a precise fit and optimal performance. Unique attributes may include a specific shape or mounting configuration that enhances its effectiveness in vibration reduction 4.

Benefits of Using the Cummins 5282929 Vibration Isolator

Utilizing the Cummins 5282929 Vibration Isolator offers several advantages. It contributes to improved ride comfort by reducing the vibrations felt by the occupants. Additionally, it plays a role in reducing wear and tear on components connected to the engine, potentially leading to longer component lifespans. There may also be a slight increase in fuel efficiency due to the reduced strain on the engine and transmission system 5.

Installation Considerations

When installing the Cummins 5282929 Vibration Isolator, it is important to follow guidelines and best practices to ensure proper function and longevity. Preparatory steps may include cleaning the mounting surfaces and inspecting the isolator for any defects. Tools required for installation might include wrenches and possibly a torque wrench to ensure proper tightening of fasteners. Alignment procedures should be followed to ensure the isolator is correctly positioned and secured 6.

Troubleshooting Common Issues

Common issues with the Cummins 5282929 Vibration Isolator may include excessive vibrations, which could indicate improper installation or wear of the isolator. Troubleshooting steps may involve rechecking the installation, inspecting the isolator for signs of damage or wear, and ensuring that all fasteners are properly tightened. Solutions may range from reinstallation to replacement of the isolator if it is found to be defective or worn 7.

Maintenance Tips

Regular maintenance of the Cummins 5282929 Vibration Isolator is important to ensure its longevity and optimal performance. This may include periodic inspection for signs of wear or damage, cleaning to remove any debris that may accumulate, and checking the tightness of fasteners. Adhering to recommended inspection intervals and performing routine maintenance can help in identifying issues before they lead to more significant problems 8.

Compatibility and Applications

The Cummins 5282929 Vibration Isolator is designed for specific types of trucks and engines, with applications where it is particularly beneficial. Its design and features are tailored to fit and function within these applications, ensuring effective vibration isolation 9.

Cummins Corporation Overview

Cummins Inc. is a global power leader that designs, manufactures, and distributes engines, filtration, and power generation products. With a history of innovation and a broad product range, Cummins has established a reputation for quality and reliability in the commercial truck industry. The company’s commitment to excellence is reflected in its products, including the Cummins 5282929 Vibration Isolator 10.

Role of Part 5282929 Vibration Isolator in Engine Systems

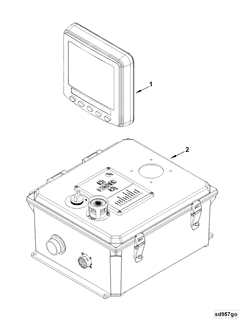

The part 5282929 Vibration Isolator is integral to maintaining the operational integrity and efficiency of various engine systems. When integrated into the Control Panel, it ensures that the vibrations generated by the engine do not interfere with the sensitive electronic components housed within, thereby maintaining accurate readings and reliable functionality.

In the context of Package and Product Installation, the Vibration Isolator serves to dampen the vibrational forces that could otherwise lead to premature wear or failure of installed components. This is particularly important in ensuring that the Panel remains securely mounted and operational over extended periods.

For the Engine Instrument System, the isolator plays a significant role in preserving the precision of measurements. By reducing the transmission of vibrations to the instruments, it helps in obtaining consistent and reliable data, which is essential for accurate engine monitoring and diagnostics.

Furthermore, within the Engine Monitoring framework, the isolator contributes to the stability of the monitoring equipment. This ensures that the data collected is free from vibrational noise, allowing for more accurate assessments of engine performance and condition.

Overall, the integration of the part 5282929 Vibration Isolator across these components enhances the durability, accuracy, and reliability of engine systems, facilitating smoother operation and longer service life 11.

Conclusion

The Cummins 5282929 Vibration Isolator plays a crucial role in the operation of commercial trucks by reducing engine vibrations, thereby contributing to a smoother ride, reduced wear on components, and potentially improved fuel efficiency. Its design, featuring high-quality materials and engineering, ensures effective vibration absorption and dampening. Regular maintenance and proper installation are key to maximizing the benefits of this isolator, ensuring the longevity and optimal performance of the truck’s engine system.

-

Hilgers, Michael. The Diesel Engine Second Edition. Springer Nature, 2023.

↩ -

Lakshminarayanan, P. A., and Avinash Kumar Agarwal. Design and Development of Heavy Duty Diesel Engines: A Handbook. Springer, 2019.

↩ -

Naunheimer, Harald, et al. Automotive Transmissions Fundamentals Selection Design and Application. Springer Vieweg, 2011.

↩ -

Gifford, Clive. Cars Encyclopedia. DK Publishing, 2014.

↩ -

Cummins Inc. Operation and Maintenance Manual for ISG12 CM2880 G107, Bulletin Number 4332692.

↩ -

Cummins Inc. Operation and Maintenance Manual for ISG12 CM2880 G107, Bulletin Number 4332692.

↩ -

Cummins Inc. Operation and Maintenance Manual for ISG12 CM2880 G107, Bulletin Number 4332692.

↩ -

Cummins Inc. Operation and Maintenance Manual for ISG12 CM2880 G107, Bulletin Number 4332692.

↩ -

Cummins Inc. Operation and Maintenance Manual for ISG12 CM2880 G107, Bulletin Number 4332692.

↩ -

Cummins Inc. Operation and Maintenance Manual for ISG12 CM2880 G107, Bulletin Number 4332692.

↩ -

Cummins Inc. Operation and Maintenance Manual for ISG12 CM2880 G107, Bulletin Number 4332692.

↩

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.