This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

The Cummins 5283506 Wiring Harness is a specialized component designed for use in commercial trucks. It serves as a part of the vehicle’s electrical system, facilitating the connection between various electrical components and the truck’s power source. This Cummins part is significant for ensuring the reliable operation of the truck’s electrical systems, which are vital for the overall functionality and performance of the vehicle.

Basic Concepts of Wiring Harnesses

A wiring harness is an assembly of wires, connectors, and sometimes switches that transmit electrical power and signals between different components within a vehicle. It consists of multiple wires bundled together, often protected by a sheath or conduit, to prevent damage and reduce the risk of short circuits. Within a vehicle’s electrical system, the wiring harness plays a role by providing a structured and organized method for distributing power and signals to various electrical components, such as lights, sensors, and control units 1.

Purpose of the 5283506 Wiring Harness

This part is specifically designed to serve the electrical needs of commercial trucks. It plays a role in connecting the truck’s battery to its electrical components, ensuring that power is efficiently distributed throughout the vehicle. This harness is tailored to meet the demanding requirements of commercial truck applications, providing reliable electrical connections in environments that may expose the wiring to vibrations, temperature extremes, and other challenging conditions.

Key Features

The 5283506 Wiring Harness is characterized by several key features that enhance its performance and durability. Its design incorporates high-quality materials that are resistant to wear, corrosion, and environmental factors. The harness is engineered to withstand the rigors of commercial truck operations, ensuring long-lasting reliability. Additionally, it features precise connector placements and secure fastening points to maintain integrity under dynamic conditions.

Benefits

The use of the 5283506 Wiring Harness in commercial trucks offers several benefits. It contributes to improved reliability by ensuring stable and consistent electrical connections. This leads to enhanced efficiency in the truck’s electrical system, as components receive the necessary power and signals without interruption. Furthermore, the harness plays a role in promoting safety by reducing the risk of electrical faults that could lead to malfunctions or hazards.

Installation Process

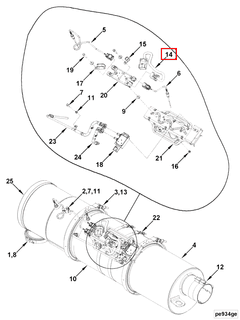

Installing the 5283506 Wiring Harness requires careful attention to detail and adherence to best practices. The process involves identifying the correct routing paths for the harness within the truck, securing it in place with appropriate fasteners, and connecting it to the vehicle’s electrical components using the provided connectors. Tools such as wire strippers, crimping tools, and electrical tape may be required. It is important to follow the manufacturer’s instructions closely to ensure a successful installation.

Troubleshooting and Maintenance

Common issues with the 5283506 Wiring Harness may include loose connections, damaged wires, or corroded terminals. Troubleshooting involves inspecting the harness for visible signs of damage or wear, testing electrical connections for continuity, and addressing any issues promptly. Regular maintenance practices, such as cleaning terminals and inspecting the harness for signs of wear, can help ensure optimal performance and longevity.

Safety Considerations

When working with the 5283506 Wiring Harness, it is important to observe safety considerations to prevent accidents or injuries. This includes disconnecting the truck’s battery before beginning any work on the electrical system, using insulated tools to avoid electrical shocks, and ensuring that all connections are secure and properly insulated after installation. Adhering to these safety practices helps protect both the technician and the vehicle.

Cummins Overview

Cummins Inc. is a well-established manufacturer known for producing high-quality automotive components, including wiring harnesses. With a rich history of innovation and a reputation for excellence, Cummins has become a trusted name in the automotive industry. The company’s commitment to quality and performance is reflected in its products, which are designed to meet the demanding requirements of commercial vehicle applications.

Cummins Engine Wiring Harness 5283506

The Cummins Wiring Harness part number 5283506 is a critical component designed to integrate seamlessly with specific Cummins engine models. This wiring harness is engineered to ensure reliable electrical connections, facilitating the smooth operation of various engine systems.

QSL9 CM2250 and QSL9 CM2350 L102

For the QSL9 CM2250 and QSL9 CM2350 L102 engines, the wiring harness 5283506 plays a pivotal role in managing the electrical pathways necessary for engine performance. This harness is meticulously crafted to fit the unique electrical architecture of these engines, ensuring that all necessary components receive the correct power and signals.

The harness is designed to connect to the engine’s control module, sensors, and other electrical components, providing a robust and dependable electrical network. This ensures that the engine can operate efficiently and reliably, maintaining optimal performance under various conditions.

The integration of the wiring harness with these engines is straightforward, thanks to its precise design and compatibility with the engine’s electrical system. This compatibility minimizes the risk of electrical faults and ensures that the engine can function without interruptions, enhancing overall reliability and performance.

Role of Part 5283506 Wiring Harness in Engine Systems

The Part 5283506 Wiring Harness is an integral component in the electrical architecture of modern engine systems, particularly those equipped with aftertreatment devices. This wiring harness facilitates the connection between various electrical components, ensuring seamless communication and operation within the engine system.

Integration with Aftertreatment Devices

In engine systems fitted with aftertreatment devices, the Part 5283506 Wiring Harness plays a significant role in managing the electrical connections required for these components to function effectively. Aftertreatment devices, such as Diesel Particulate Filters (DPFs) and Selective Catalytic Reduction (SCR) systems, rely on precise electrical signals to operate sensors, actuators, and control modules. The wiring harness ensures that these signals are transmitted accurately and efficiently, allowing the aftertreatment device to monitor and regulate emissions in real-time.

Connection to Engine Control Unit (ECU)

The wiring harness also establishes a vital link between the aftertreatment device and the Engine Control Unit (ECU). This connection enables the ECU to receive data from sensors within the aftertreatment system, such as temperature sensors and pressure sensors. With this data, the ECU can make informed decisions to optimize engine performance while ensuring compliance with emissions regulations. The wiring harness thus acts as a conduit for critical information flow within the engine system.

Support for Diagnostic and Monitoring Systems

Furthermore, the Part 5283506 Wiring Harness supports onboard diagnostic (OBD) systems by providing the necessary electrical pathways for data transmission. This allows mechanics and engineers to monitor the health and performance of the aftertreatment device and other engine components. By facilitating easy access to diagnostic data, the wiring harness aids in the timely identification and resolution of potential issues, contributing to the overall reliability and efficiency of the engine system.

Facilitation of System Updates and Upgrades

As engine technology evolves, the ability to update and upgrade system components becomes increasingly important. The Part 5283506 Wiring Harness is designed to accommodate these changes, allowing for the integration of new sensors, actuators, or control modules without requiring a complete overhaul of the engine’s electrical system. This flexibility ensures that engine systems can be adapted to meet changing emissions standards and performance requirements over time.

Conclusion

The 5283506 Wiring Harness is a foundational element in the electrical infrastructure of engine systems, especially those incorporating aftertreatment devices. Its role in connecting, communicating, and facilitating the operation of various components underscores its importance in the efficient and effective functioning of modern engine technologies.

-

Stone, R. (2012). Introduction to Internal Combustion Engines, Fourth Edition. Macmillan.

↩

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.