This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

Introduction

The Cummins 5294357 Inlet Catalyst Module is a component designed for use in commercial trucks. It is engineered to enhance the efficiency of the exhaust system and plays a role in reducing emissions. This module is part of Cummins’ commitment to improving engine performance while adhering to stringent environmental regulations.

Function and Operation

The Inlet Catalyst Module is positioned within the exhaust system, typically upstream of the Diesel Particulate Filter (DPF). Its operation involves catalyzing the oxidation of hydrocarbons and carbon monoxide present in the exhaust gases. This process converts these pollutants into less harmful substances such as carbon dioxide and water vapor. The module interacts with the engine’s exhaust system by receiving raw exhaust gases and facilitating a chemical reaction that reduces the overall emission output 1.

Purpose of the Inlet Catalyst Module

The primary role of the Inlet Catalyst Module is to reduce emissions from commercial trucks. By catalyzing the oxidation of harmful exhaust components, it contributes to cleaner air quality. Additionally, the module aids in improving engine performance by ensuring that the exhaust system operates efficiently. This component is integral to meeting environmental regulations, as it helps trucks comply with emission standards set by various authorities 2.

Key Features

The Cummins 5294357 Inlet Catalyst Module boasts several key features that enhance its functionality. Its design incorporates advanced catalytic materials that maximize the efficiency of the oxidation process. The module is constructed using durable materials to withstand the high temperatures and pressures of the exhaust system. Technological advancements in the module’s design ensure it can handle the demanding conditions of commercial truck operations.

Benefits

Utilizing the Inlet Catalyst Module offers several advantages. It contributes to improved fuel efficiency by optimizing the exhaust system’s performance. Additionally, the module can lead to reduced maintenance costs due to its durable construction and efficient operation. Enhanced engine longevity is another benefit, as the module helps maintain optimal exhaust system conditions, reducing wear and tear on other components.

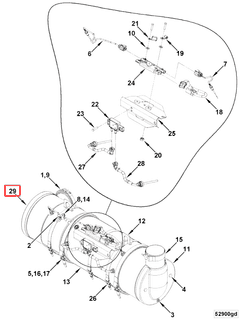

Installation Process

Proper installation of the Inlet Catalyst Module is crucial for its effective operation. The process involves several steps: first, ensuring the exhaust system is clean and free of obstructions; second, positioning the module in the designated location within the exhaust path; third, securing it with the appropriate fasteners; and finally, verifying that all connections are tight and secure. It is important to follow manufacturer guidelines to ensure correct installation.

Common Issues and Troubleshooting

Typical problems associated with the Inlet Catalyst Module may include reduced efficiency due to catalyst poisoning or physical damage. Troubleshooting steps involve inspecting the module for signs of damage, checking for proper installation, and ensuring that the exhaust system is free of contaminants that could impair the module’s function. Solutions may range from cleaning the module to replacing it if damage is detected.

Maintenance Tips

Regular maintenance practices are recommended to ensure the optimal performance and longevity of the Inlet Catalyst Module. This includes periodic inspections for signs of wear or damage, ensuring that the exhaust system is clean, and following manufacturer-recommended service intervals. Proper maintenance helps prevent issues and ensures the module continues to operate efficiently.

Regulatory Compliance

The Inlet Catalyst Module plays a role in helping trucks comply with emissions regulations and standards. By reducing the levels of harmful emissions, it ensures that vehicles meet the requirements set by environmental agencies. This compliance is crucial for operators to avoid penalties and maintain their fleet’s operational status.

Cummins Overview

Cummins Inc. is a global power leader that designs, manufactures, and distributes a wide range of power solutions. With a history spanning over a century, Cummins has established itself as a key player in the commercial truck industry. The company is known for its innovation in engine technology and commitment to sustainability, providing solutions that meet the evolving needs of the transportation sector.

Conclusion

The Cummins 5294357 Inlet Catalyst Module is a vital component in the exhaust system of commercial trucks, designed to enhance engine performance and reduce emissions. Its advanced design, durable construction, and efficient operation contribute to improved fuel efficiency, reduced maintenance costs, and enhanced engine longevity. Proper installation, regular maintenance, and adherence to regulatory compliance are essential for maximizing the benefits of this Cummins part.

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.