This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

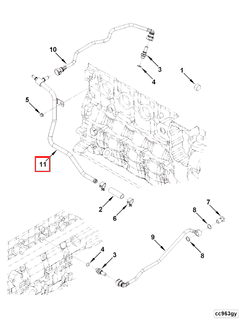

The Compressor Water Outlet Tube, identified by part number 5294543, is a component manufactured by Cummins, a well-established name in the automotive industry. This tube is integral to the cooling systems of heavy-duty trucks, ensuring efficient operation and longevity of the engine and compressor.

Basic Concepts

The Compressor Water Outlet Tube operates on fundamental principles of fluid dynamics and thermal management. It facilitates the flow of coolant from the compressor to other parts of the cooling system, interacting with components such as the radiator and engine block. This interaction helps in dissipating heat generated during the compression process, maintaining a stable operating temperature 1.

Purpose and Function

In the context of heavy-duty truck operations, the Compressor Water Outlet Tube serves to maintain optimal temperatures for both the compressor and the engine. By efficiently routing coolant, it plays a role in preventing overheating, which can lead to reduced performance and potential damage to engine components 2.

Key Features

The Compressor Water Outlet Tube (5294543) is characterized by several key features that enhance its performance and durability. It is constructed from high-quality materials resistant to corrosion and high temperatures. Its design includes precise fittings and connections that ensure a secure and leak-free integration within the cooling system. Additionally, the tube may feature reinforced sections to withstand the pressures and vibrations typical in heavy-duty applications 3.

Benefits

The inclusion of the Compressor Water Outlet Tube in a truck’s cooling system offers several benefits. It contributes to improved engine efficiency by ensuring that the compressor operates within its optimal temperature range. The durable construction of the tube enhances the overall reliability of the cooling system, reducing the likelihood of failures and the need for frequent repairs 4.

Installation and Integration

Proper installation of the Compressor Water Outlet Tube is vital for its effective function. It should be integrated into the truck’s cooling system according to manufacturer guidelines, ensuring all connections are secure and free from leaks. Best practices include using the correct torque specifications for fastenings and verifying the alignment of the tube with other components to facilitate smooth coolant flow.

Maintenance and Troubleshooting

Routine maintenance of the Compressor Water Outlet Tube involves regular inspections for signs of wear, corrosion, or leaks. Cleaning the tube and its connections can prevent buildup that might impede coolant flow. Troubleshooting may involve checking for proper coolant levels and pressure, as well as inspecting for any obstructions or damage that could affect performance.

Common Issues and Solutions

Common issues with the Compressor Water Outlet Tube may include leaks, blockages, or corrosion. Solutions often involve repairing or replacing damaged sections, ensuring all connections are tight, and using corrosion-resistant coolant. Preventive measures include regular maintenance checks and using high-quality coolant to protect against corrosion.

Cummins Overview

Cummins is a renowned manufacturer in the automotive industry, particularly known for its heavy-duty truck components. With a history of innovation and quality, Cummins offers a wide range of products designed to enhance the performance, efficiency, and reliability of vehicles. Their components, including the Compressor Water Outlet Tube, are engineered to meet the demanding requirements of heavy-duty applications.

Compatibility of Compressor Water Outlet Tube (Part 5294543) with Cummins Engines

The Compressor Water Outlet Tube, identified by part number 5294543, is a critical component in the cooling system of certain Cummins engines. This part is designed to facilitate the efficient flow of coolant from the compressor to the radiator, ensuring optimal engine temperature regulation.

B6.7 Engines

The B6.7 engine series benefits from the precise engineering of the 5294543 part. This component is integral to maintaining the coolant flow path, which is essential for the engine’s thermal management system. The B6.7 engines, known for their robust performance and reliability, integrate this part seamlessly, enhancing their operational efficiency.

CM2350 Engines

The CM2350 engine also incorporates the 5294543 Compressor Water Outlet Tube. This part ensures that the coolant is effectively routed, contributing to the engine’s cooling efficiency. The CM2350 engines, designed for heavy-duty applications, rely on such precision components to maintain their performance under demanding conditions.

B135B Engines

Similarly, the B135B engine series utilizes the 5294543 part for its cooling system. This component is crucial for the proper functioning of the engine’s thermal management, ensuring that the coolant is efficiently circulated. The B135B engines, known for their versatility and reliability, integrate this part to support their operational needs.

Grouping of Engines

The Compressor Water Outlet Tube (5294543) is compatible with the B6.7, CM2350, and B135B engines, highlighting its versatility and importance across different engine models. This part’s design and functionality are tailored to meet the specific cooling requirements of these engines, ensuring they operate efficiently and reliably.

Role of Part 5294543 Compressor Water Outlet Tube in Engine Systems

The Compressor Water Outlet Tube (part 5294543) is an essential component in the efficient operation of engine systems, particularly in those utilizing compressor coolant systems. This tube serves as a conduit for the coolant, ensuring that it is effectively circulated from the compressor to other parts of the engine system.

In the context of plumbing, the Compressor Water Outlet Tube is integral to maintaining the structural integrity and efficiency of the coolant flow. It connects to various plumbing components, such as hoses and fittings, to create a seamless pathway for the coolant. This ensures that the coolant is delivered consistently to critical areas of the engine, enhancing overall performance and reliability.

When considering the compressor coolant system, the role of the Compressor Water Outlet Tube becomes even more pronounced. The tube facilitates the discharge of coolant from the compressor, which is vital for dissipating heat generated during compression cycles. This heat management is essential for preventing overheating and ensuring that the compressor operates within optimal temperature ranges.

Additionally, the tube interacts with other components such as the radiator and heat exchangers. By providing a direct route for the coolant to travel from the compressor to these cooling elements, the tube helps in maintaining a balanced thermal environment within the engine system. This, in turn, contributes to the longevity and efficiency of the compressor and associated components.

Conclusion

In summary, the Compressor Water Outlet Tube (part 5294543) plays a significant role in the plumbing and compressor coolant systems by ensuring efficient coolant circulation, effective heat dissipation, and maintaining the structural integrity of the coolant pathway. Its compatibility with various Cummins engines underscores its importance in maintaining engine efficiency and reliability.

-

Automotive Braking Systems CDX Master Automotive Technician Series, Nicholas Goodnight and Kirk VanGelder, Jones Bartlett Learning, 2019.

↩ -

Automotive Mechatronics Operational and Practical Issues Volume 1, BT Fijalkowski, Springer, 2011.

↩ -

Fundamentals of Integrated Vehicle Realization, Mohamed ElSayed PE, SAE International, 2017.

↩ -

Motor Vehicle Mechanics Textbook, Fifth Edition, F. K. Sully, Heinemann Professional Publishing, 1998.

↩

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.