This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

Introduction

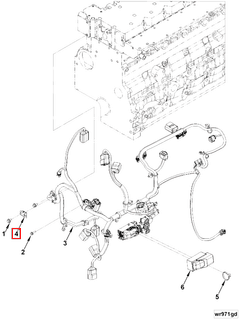

The Cummins 5294580 Wire Retaining Clip is a component designed to secure electrical wires and cables within heavy-duty trucks. Its role is significant in maintaining the integrity and efficiency of the truck’s electrical system, ensuring that wires remain in place and protected from potential damage or interference.

Basic Concepts of Wire Retaining Clips

Wire retaining clips are small yet vital components used across automotive and industrial applications. Their primary function is to hold wires and cables securely in place, preventing them from moving or vibrating excessively, which could lead to wear, disconnection, or damage. These clips are typically made from durable materials to withstand the environmental conditions and mechanical stresses encountered in their applications 1.

Purpose of the 5294580 Wire Retaining Clip

The 5294580 Wire Retaining Clip is specifically designed for use in Cummins engines and other heavy-duty truck systems. It plays a role in securing electrical wires and cables within the engine compartment and other critical areas. By keeping wires organized and protected, it helps maintain the electrical system’s reliability and performance, reducing the risk of electrical issues that could arise from unsecured or damaged wires 2.

Key Features

The 5294580 Wire Retaining Clip is constructed from high-quality materials, ensuring durability and resistance to the harsh conditions found in heavy-duty truck environments. Its design allows for easy installation and secure retention of wires, with features that enhance its functionality and longevity. The clip’s unique attributes include a robust construction that can withstand significant mechanical stress and environmental exposure, ensuring long-term performance.

Benefits

Utilizing the 5294580 Wire Retaining Clip offers several advantages. It improves wire management by keeping cables organized and secured, which can simplify maintenance and repair processes. Additionally, it reduces the risk of electrical issues by preventing wires from coming loose or being damaged, thereby enhancing the overall reliability of the truck’s electrical system.

Installation Process

Installing the 5294580 Wire Retaining Clip involves several steps to ensure secure and effective placement. First, identify the location where the clip is needed, typically near wiring harnesses or cable runs. Use the appropriate tools to position the clip around the wire, ensuring it is snug but not overly tight to avoid damaging the wire insulation. Follow best practices for securing the clip, such as using zip ties or additional fasteners if necessary, to ensure the wire remains in place under all operating conditions.

Troubleshooting Common Issues

Common problems associated with wire retaining clips include loose connections or damage to the clip itself. To address these issues, inspect the clips regularly for signs of wear or displacement. If a clip appears loose or damaged, it should be replaced to maintain the integrity of the wire retention system. Ensuring that all clips are properly installed and secured can prevent many common issues.

Maintenance Tips

Regular maintenance of the 5294580 Wire Retaining Clip involves periodic inspection for signs of wear, damage, or displacement. Check the clips during routine maintenance intervals or whenever working near the affected wiring. If any clips show signs of degradation or if wires appear unsecured, consider replacement to prevent potential electrical issues. Keeping the clips in good condition ensures the continued reliability of the truck’s electrical system.

About Cummins

Cummins Inc. is a global power leader that designs, manufactures, and distributes a wide range of power solutions, including engines, filtration, and emissions solutions. With a history of innovation and a commitment to quality, Cummins serves customers in approximately 190 countries and territories through a network of company-owned and independent distributor facilities and dealerships. The company’s product range includes engines for on-highway, off-highway, and industrial applications, demonstrating its versatility and importance across various sectors.

Wire Retaining Clip (Part 5294580) Compatibility with Cummins Engines

The Wire Retaining Clip, identified by the part number 5294580, is a crucial component in the electrical systems of various Cummins engines. This part is designed to secure and organize wiring harnesses, ensuring that they remain in place and do not interfere with other engine components.

Compatibility with ISB6.7 Engines

The Wire Retaining Clip is compatible with the ISB6.7 engine series, which includes models such as the CM2350 B101 and CM2180 B118. These engines are known for their robust performance and reliability, often used in heavy-duty applications such as trucks and industrial machinery.

-

ISB6.7 CM2350 B101: This engine variant benefits from the Wire Retaining Clip by maintaining the integrity of its wiring system. The clip helps in preventing wire movement and potential damage, which is crucial for the engine’s operational efficiency and longevity.

-

ISB6.7 CM2180 B118: Similarly, the ISB6.7 CM2180 B118 engine utilizes the Wire Retaining Clip to ensure that the wiring is neatly managed. This organization is vital for preventing electrical issues that could arise from loose or misplaced wires.

Grouping for Enhanced Understanding

When considering the use of the Wire Retaining Clip across different engine models, it is important to recognize that the clip’s primary function remains consistent. Its role in securing and organizing wiring harnesses is essential for maintaining the electrical integrity of the engine.

By grouping the ISB6.7 engines together, it becomes clear that the Wire Retaining Clip is a versatile component that can be applied across various models within this series. This compatibility ensures that technicians and mechanics can use the same part across different engine variants, simplifying maintenance and repair processes.

Role of Part 5294580 Wire Retaining Clip in Engine Systems

The part 5294580 Wire Retaining Clip is instrumental in maintaining the integrity and functionality of various engine systems by ensuring secure connections and preventing unwanted movement of wires.

Harness Integration

In the context of a harness, the Wire Retaining Clip plays a significant role in organizing and securing the multitude of wires that transmit electrical signals and power throughout the engine system. By clipping wires together, it prevents them from tangling or coming loose, which could lead to intermittent connections or complete failure of electrical components. This organization is vital for the efficient operation of the engine, as it ensures that all electrical signals are transmitted reliably and without interference.

Electronic Control Module (ECM) Wiring

When it comes to the Electronic Control Module (ECM) wiring, the Wire Retaining Clip is equally important. The ECM relies on precise and consistent electrical signals to manage engine operations, including fuel injection, ignition timing, and emissions control. The clip helps to maintain the correct positioning of wires, reducing the risk of shorts or opens that could disrupt the ECM’s functionality. This is particularly important in high-vibration environments typical of engine compartments, where unsecured wires could otherwise become damaged or dislodged.

Conclusion

The Cummins 5294580 Wire Retaining Clip is a vital component in the maintenance and reliability of heavy-duty truck electrical systems. By securing and organizing wiring harnesses, it ensures the efficient and uninterrupted operation of engine systems, contributing to the overall performance and longevity of Cummins engines.

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.