This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

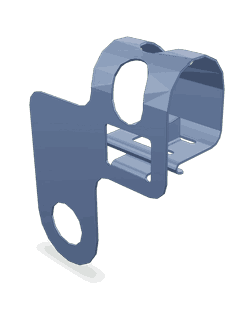

The 5294581 Wire Retaining Clip, manufactured by Cummins, is a component designed to secure wires and cables within commercial trucks. Its role is to maintain the integrity and organization of the electrical system, ensuring that wires remain in place and are protected from potential damage. Cummins, a well-established manufacturer in the automotive industry, produces this clip to meet the demanding requirements of commercial vehicle operations.

Basic Concepts of Wire Retaining Clips

Wire retaining clips are small yet vital components used across automotive and industrial applications. Their primary function is to secure wires and cables, preventing them from moving or becoming dislodged. This is particularly important in environments where vibrations and movement are common, such as in the engine compartment of a truck. By holding wires in place, these clips help maintain the efficiency and safety of the electrical systems 1.

Purpose of the 5294581 Wire Retaining Clip

This Cummins part is specifically designed to secure wires within the engine compartment or other critical areas of a truck. It plays a role in maintaining the organization and protection of the electrical system by ensuring that wires do not come into contact with moving parts or sharp edges. This helps in reducing the risk of electrical issues that could arise from damaged or disconnected wires 2.

Key Features

The 5294581 is characterized by its durable design and material composition. It is made from materials that offer resistance to environmental factors such as heat, moisture, and chemical exposure. This durability ensures that the clip remains effective over the long term. Additionally, the clip is designed for ease of installation, allowing for quick and secure attachment to wires and surfaces 3.

Benefits

Using this part offers several advantages. It improves wire management by keeping cables organized and in place, which can simplify maintenance and troubleshooting processes. The clip also reduces the risk of electrical issues by protecting wires from damage, thereby enhancing the safety and reliability of the truck’s electrical systems 4.

Installation Process

Installing the 5294581 involves a few straightforward steps. First, identify the location where the wire needs to be secured. Then, position the clip around the wire, ensuring it is aligned correctly. Use the appropriate tools to fasten the clip securely in place. It is important to follow best practices to ensure that the wire is properly secured and that the clip is firmly attached to prevent any movement.

Troubleshooting and Maintenance

Common issues with wire retaining clips may include loose connections or damage to the clip itself. Regular inspection of the clips can help identify these problems early. Maintenance tips include checking the clips periodically for signs of wear or damage and replacing them if necessary to ensure continued effectiveness. Proper installation and maintenance can significantly extend the longevity and reliability of the wire retaining system.

Safety Considerations

When installing or maintaining wire retaining clips, it is important to observe safety practices to prevent electrical hazards and ensure personal safety. This includes wearing appropriate personal protective equipment, ensuring that the electrical system is de-energized during installation or maintenance, and following manufacturer guidelines for safe handling and use of the clips.

Cummins: Manufacturer Overview

Cummins is a reputable manufacturer with a long history in the automotive industry. Known for their commitment to quality and innovation, Cummins produces a wide range of components designed to meet the rigorous demands of commercial vehicles. Their products are recognized for reliability and performance, making them a trusted choice for fleet operators and maintenance professionals.

Wire Retaining Clip (Part 5294581) Compatibility with Cummins Engines

The Wire Retaining Clip, identified by the part number 5294581, is a crucial component in the electrical systems of various Cummins engines. This part is designed to secure and organize wiring harnesses, ensuring that electrical connections remain stable and protected from potential damage.

ISB6.7 and CM2350 Engines

The ISB6.7 and CM2350 engines, both known for their robust performance and reliability, utilize the Wire Retaining Clip to maintain the integrity of their electrical systems. In these engines, the clip is typically used to secure wiring harnesses that run along the engine’s frame or other structural components. This helps in preventing the wires from becoming dislodged or frayed, which could lead to electrical failures or other issues.

B101 Engine

The B101 engine, another member of the Cummins family, also benefits from the use of the Wire Retaining Clip. In this engine, the clip is often employed to manage the routing and securing of wiring harnesses that are integral to the engine’s operation. By keeping the wiring in place, the clip helps to ensure that the electrical system functions smoothly and efficiently, contributing to the overall reliability of the engine.

Grouping Considerations

When considering the use of the Wire Retaining Clip across different engines, it is important to note that while the specific applications may vary, the fundamental purpose remains the same: to secure and protect wiring harnesses. This commonality allows for a broader understanding of how the part functions within the Cummins engine ecosystem, facilitating easier maintenance and repair processes.

Role of Part 5294581 Wire Retaining Clip in Engine Systems

The part 5294581 Wire Retaining Clip is an essential component in maintaining the integrity and functionality of the wiring systems within engine assemblies. It is specifically designed to secure wires in place, ensuring they remain organized and protected from potential damage.

Harness Integration

In the context of a harness, the 5294581 Wire Retaining Clip plays a significant role by securing individual wires or bundles of wires. This is particularly important in areas where the harness runs close to moving parts or high-vibration zones. By keeping the wires firmly in place, the clip helps prevent chafing, abrasion, and potential short circuits. This is vital for maintaining the reliability of the electrical connections throughout the engine system.

Electronic Control Module (ECM) Wiring

When it comes to the wiring associated with the Electronic Control Module (ECM), the 5294581 Wire Retaining Clip ensures that the sensitive electronic connections remain stable and undisturbed. The ECM relies on precise and consistent data from various sensors and components, and any disruption in the wiring can lead to inaccurate readings or system failures. The clip helps maintain the correct positioning of wires, reducing the risk of interference and ensuring that the ECM receives accurate and timely information.

Conclusion

In summary, the 5294581 Wire Retaining Clip is a fundamental component in the engine’s electrical system, contributing to the overall reliability and performance of the engine by securing and protecting vital wiring. Its durable design, ease of installation, and compatibility with various Cummins engines make it an indispensable part for maintaining the integrity of the electrical systems in commercial trucks.

-

Xin, Qianfan. Diesel Engine System Design. Woodhead Publishing Limited, 2011.

↩ -

Ferrari, Alessandro, and Pietro Pizzo. Injection Technologies: Mixture Formation Strategies. SAE International, 2022.

↩ -

Reif, Konrad. Automotive Mechatronics. Springer Vieweg, 2015.

↩ -

Bennett, Sean. Modern Diesel Technology: Light Duty Diesels. Cengage Learning, 2012.

↩

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.