This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

Introduction

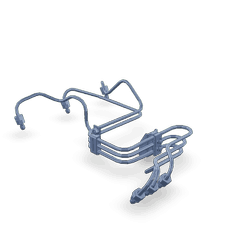

The Injector Fuel Supply Tube 5298308 is a component designed for use in Cummins engines, specifically tailored for commercial trucks. Its purpose is to facilitate the efficient delivery of fuel from the fuel system to the injectors, ensuring optimal engine performance. This Cummins part is integral to the operation of commercial trucks, contributing to their reliability and efficiency on the road.

Basic Concepts of Injector Fuel Supply Tubes

An Injector Fuel Supply Tube is a conduit within the fuel system that carries fuel from the fuel rail to the injectors. Its function is to provide a consistent and pressurized flow of fuel, which is crucial for the injectors to atomize fuel properly during combustion. This contributes to the overall performance of a truck’s engine by ensuring that fuel is delivered efficiently and effectively, which in turn supports power output and fuel economy 1.

Purpose of the Injector Fuel Supply Tube

The Injector Fuel Supply Tube plays a specific role in the fuel delivery system of Cummins engines. It is designed to ensure that fuel reaches the injectors under the correct pressure and in the right quantity. This part helps maintain the integrity of the fuel supply, preventing leaks and ensuring that the injectors receive a consistent flow of fuel, which is vital for engine operation.

Key Features

The Injector Fuel Supply Tube is constructed from high-quality materials that are resistant to the corrosive effects of diesel fuel. Its design includes precise engineering to ensure a snug fit within the fuel system, minimizing the risk of leaks. Additionally, the tube features smooth internal surfaces to reduce fuel flow resistance, enhancing the efficiency of fuel delivery. These characteristics contribute to the tube’s performance and durability, making it a reliable component in the fuel system 2.

Benefits

Utilizing the Injector Fuel Supply Tube offers several advantages. It contributes to improved fuel efficiency by ensuring that fuel is delivered to the injectors without unnecessary loss or pressure drop. Enhanced engine performance is another benefit, as consistent fuel delivery supports optimal combustion. Reliability is also increased, as the tube’s design and material composition are tailored to withstand the demanding conditions of commercial truck operation. These benefits collectively impact the overall operation of commercial trucks, leading to more efficient and dependable performance.

Installation Process

Installing the Injector Fuel Supply Tube requires careful attention to detail. The process involves disconnecting the old tube, cleaning the fuel system components, and then fitting the new tube into place. Tools such as wrenches and torque wrenches may be necessary to secure connections properly. It is important to follow manufacturer guidelines to ensure that the tube is installed correctly, which includes checking for proper alignment and secure fittings to prevent leaks.

Troubleshooting Common Issues

Common issues with the Injector Fuel Supply Tube may include leaks or blockages. To address these problems, it is important to inspect the tube and its connections for signs of wear or damage. If a leak is detected, the tube may need to be replaced or resealed. Blockages can often be cleared by flushing the fuel system or replacing the affected component. Regular inspections can help identify potential issues before they lead to more significant problems.

Maintenance Tips

To ensure the longevity and optimal performance of the Injector Fuel Supply Tube, regular maintenance is recommended. This includes periodic inspections for signs of wear, corrosion, or leaks. Cleaning the fuel system components and replacing the tube as part of routine maintenance can help prevent issues. Following a maintenance schedule that aligns with the manufacturer’s recommendations will contribute to the tube’s durability and the engine’s efficiency.

Cummins: A Brief Overview

Cummins Inc. is a global power leader that designs, manufactures, and distributes a wide range of power solutions. With a history spanning over a century, Cummins has established a reputation for innovation, quality, and customer satisfaction in the commercial truck industry. The company’s commitment to advancing technology and delivering reliable products underscores its position as a trusted partner for commercial vehicle operators worldwide.

Compatibility with Cummins Engines

The Injector Fuel Supply Tube, identified by the part number 5298308, is a critical component in the fuel delivery system of various Cummins engines. This part is designed to ensure a reliable and efficient fuel supply to the injectors, which is essential for maintaining optimal engine performance.

Compatibility with Cummins Engines

-

6B5.9 Engine Series

- The Injector Fuel Supply Tube is specifically engineered to fit seamlessly within the 6B5.9 engine series. This compatibility ensures that the fuel supply tube integrates well with the engine’s design, providing a secure and efficient fuel pathway to the injectors.

-

Other Cummins Engine Models

- While the primary focus is on the 6B5.9 engine series, the Injector Fuel Supply Tube may also be compatible with other Cummins engine models. It is essential to verify the specific engine model and configuration to ensure proper fitment and functionality.

Importance of Proper Fitment

Ensuring that the Injector Fuel Supply Tube is correctly installed is crucial for the overall health and performance of the engine. A well-fitted fuel supply tube helps prevent fuel leaks, maintains consistent fuel pressure, and supports the efficient operation of the injectors. This, in turn, contributes to better fuel economy, reduced emissions, and enhanced engine longevity.

Installation Considerations

When installing the Injector Fuel Supply Tube, it is important to follow the manufacturer’s guidelines and specifications. Proper installation involves:

- Ensuring that all connections are secure and leak-free.

- Verifying that the tube is the correct length and diameter for the specific engine model.

- Using the appropriate tools and techniques to avoid damaging the fuel supply tube or other engine components.

By adhering to these guidelines, technicians and engine operators can ensure that the Injector Fuel Supply Tube functions as intended, contributing to the overall reliability and efficiency of the engine.

Role of Injector Fuel Supply Tube in Engine Systems

The Injector Fuel Supply Tube is an integral component in the fuel delivery system of an engine. It facilitates the transfer of fuel from the fuel rail to the injectors, ensuring a consistent and precise fuel supply to each cylinder. This part works in conjunction with several other components to maintain optimal engine performance.

Interaction with Fuel Rail

The fuel rail is a pressurized manifold that distributes fuel to each injector. The Injector Fuel Supply Tube connects directly to the fuel rail, allowing it to draw fuel under pressure. This pressurized fuel is essential for the injectors to atomize the fuel properly, enhancing combustion efficiency.

Connection to Fuel Injectors

Each injector is responsible for spraying a fine mist of fuel into the intake port or directly into the combustion chamber. The Injector Fuel Supply Tube ensures a secure and leak-free connection between the fuel rail and the injectors. This connection is vital for maintaining the integrity of the fuel system and preventing fuel leaks, which could lead to performance issues or safety hazards.

Integration with Fuel Pump and Filter

Upstream of the fuel rail, the fuel pump and filter play a significant role in delivering clean, pressurized fuel. The Injector Fuel Supply Tube receives this conditioned fuel and routes it to the injectors. Efficient operation of the fuel pump and filter ensures that the fuel delivered through the Injector Fuel Supply Tube is free from contaminants and at the correct pressure.

Role in Fuel Return System

In many engine systems, a fuel return line is employed to manage excess fuel that is not used by the injectors. The Injector Fuel Supply Tube indirectly interacts with this system by ensuring that the fuel delivered is within the required parameters. Proper fuel management helps in maintaining consistent engine performance across varying operating conditions.

Contribution to Engine Management System (EMS)

The Engine Management System (EMS) relies on precise fuel delivery for optimal performance. Sensors monitor various parameters such as fuel pressure, engine load, and air-fuel ratio. The Injector Fuel Supply Tube’s role in delivering consistent fuel pressure directly influences the data the EMS uses to make real-time adjustments, thereby enhancing overall engine efficiency and performance 3.

Conclusion

The Injector Fuel Supply Tube 5298308 is a critical component in the fuel delivery system of Cummins engines, ensuring efficient and reliable fuel supply to the injectors. Its proper installation, maintenance, and compatibility with various Cummins engine models are essential for optimal engine performance and longevity.

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.