This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

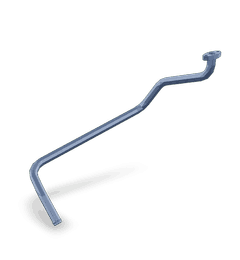

The Tur Oil Drain Tube, identified by part number 5298391, is a component manufactured by Cummins, a leader in diesel engine technology. This tube is integral to the maintenance regimen of heavy-duty trucks, facilitating the efficient drainage of oil from the engine. Its role in the operational ecosystem of commercial trucks underscores the importance of reliable components in ensuring vehicle performance and longevity 1.

Function and Operation

The Tur Oil Drain Tube operates as a conduit within the truck’s engine system, specifically designed to manage the oil drainage process. When it is time for an oil change or during routine maintenance, this tube allows for the controlled and efficient flow of used oil out of the engine. Its design ensures that oil is directed away from the engine compartment, minimizing the risk of spills and contamination. This process is vital for maintaining engine health, as it enables the removal of impurities and degraded oil, which can otherwise lead to engine wear and reduced efficiency 2.

Key Features

The Tur Oil Drain Tube is constructed from high-quality materials, ensuring durability and resistance to the harsh conditions within an engine compartment. Its design incorporates several features that enhance performance, including a secure fitting mechanism that prevents leaks and a smooth interior that facilitates unimpeded oil flow. Additionally, the tube’s length and diameter are optimized to accommodate the specific requirements of heavy-duty truck engines, ensuring compatibility and efficiency 3.

Benefits of Using the Tur Oil Drain Tube

Incorporating the Tur Oil Drain Tube into a truck’s maintenance routine offers several advantages. It contributes to improved engine efficiency by ensuring that oil changes are conducted smoothly and effectively. The ease of maintenance afforded by this tube reduces downtime and simplifies the oil change process. Furthermore, by facilitating proper oil drainage, it plays a part in extending the engine’s lifespan, underscoring its value in the maintenance of heavy-duty trucks 4.

Installation Process

Installing the Tur Oil Drain Tube requires attention to detail and adherence to safety protocols. The process involves securing the tube to the engine’s oil drain port, ensuring a tight and leak-free connection. Tools required may include wrenches for tightening connections and possibly a socket set for specific fittings. Safety precautions, such as ensuring the engine is cool and the vehicle is stable, should be observed throughout the installation process.

Maintenance and Care

To ensure the longevity and optimal performance of the Tur Oil Drain Tube, regular maintenance and care are recommended. This includes periodic inspection for signs of wear or damage, cleaning the tube and its connections to prevent blockages, and replacing the tube if it shows signs of degradation or if it becomes damaged. Adhering to these maintenance practices helps maintain the efficiency of the oil drainage system.

Troubleshooting Common Issues

Common issues associated with the Tur Oil Drain Tube may include leaks or blockages. Leaks can often be traced to loose connections or damage to the tube itself, and may be addressed by tightening connections or replacing the tube. Blockages, on the other hand, can be cleared by cleaning the tube and ensuring that debris does not obstruct the oil flow. Regular inspections can help identify and address these issues before they lead to more significant problems.

Cummins: A Brief Overview

Cummins Inc. is a global power leader that designs, manufactures, and distributes diesel and natural gas engines, as well as related technologies. With a history spanning over a century, Cummins has established itself as a pioneer in engine technology, committed to innovation, quality, and customer satisfaction. Its extensive range of products and services caters to a variety of industries, underscoring its expertise and leadership in the automotive and heavy-duty truck sectors.

Tur Oil Drain Tube for Cummins Engines

The Tur Oil Drain Tube, part number 5298391, is a critical component in the maintenance and operation of several Cummins engines. This part is designed to facilitate the drainage of oil from the turbocharger, ensuring that the turbocharger operates efficiently and reliably.

QSB6.7 M CM2250 Engines

The Tur Oil Drain Tube is specifically engineered to fit seamlessly with the QSB6.7 M CM2250 engines. These engines are known for their robust performance and reliability, often used in a variety of applications, from industrial machinery to agricultural equipment. The integration of the Tur Oil Drain Tube in these engines ensures that oil is effectively drained from the turbocharger, preventing oil accumulation that could lead to performance issues or damage.

Grouping of Engines

In addition to the QSB6.7 M CM2250, the Tur Oil Drain Tube is also compatible with other Cummins engines within the same family. This compatibility is due to the standardized design and manufacturing processes used by Cummins, ensuring that the part fits perfectly and functions as intended across multiple engine models. This standardization allows for easier maintenance and repair, as technicians can use the same part across different engine types, reducing inventory needs and simplifying the repair process.

Role of Part 5298391 Tur Oil Drain Tube in Engine Systems

The Tur Oil Drain Tube is an essential component in the maintenance and operation of engine systems, particularly those involving turbochargers. This tube is integral to the oil management system, ensuring that the turbocharger operates efficiently and reliably.

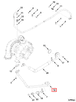

Integration with Turbocharger

In turbocharged engine systems, the turbocharger relies on a steady supply of oil for lubrication and cooling. The Tur Oil Drain Tube facilitates the return flow of oil from the turbocharger back to the engine’s oil sump. This continuous circulation helps maintain optimal oil levels within the turbocharger, preventing oil starvation and ensuring consistent performance.

Plumbing System Interaction

The Tur Oil Drain Tube is a key element in the engine’s plumbing system. It connects the oil return line from the turbocharger to the main oil return path, which leads back to the oil pan. This setup ensures that used oil is efficiently drained away from the turbocharger, reducing the risk of oil buildup and contamination. Proper drainage is vital for maintaining the turbocharger’s internal components, such as the bearings and seals, which depend on clean oil for lubrication.

Maintenance and Efficiency

By incorporating the Tur Oil Drain Tube into the engine system, mechanics and engineers can enhance the overall maintenance routine. Regular inspection and replacement of this tube, if necessary, contribute to the longevity and reliability of the turbocharger. Efficient oil drainage also aids in thermal management, as it helps dissipate heat generated during high-performance operations.

System Reliability

The integration of the Tur Oil Drain Tube into the engine’s oil management system plays a significant role in enhancing system reliability. By ensuring a consistent oil flow and proper drainage, this component helps prevent common issues such as oil leaks, turbocharger failure, and engine overheating.

Conclusion

The Tur Oil Drain Tube, part number 5298391, is a vital component that supports the efficient operation and maintenance of turbocharged engine systems. Its role in oil management and drainage is fundamental to the sustained performance and reliability of the turbocharger and the overall engine system.

-

Gifford, Clive. Cars Encyclopedia. DK Publishing, 2014.

↩ -

Bennett, Sean. Modern Diesel Technology Light Duty Diesels. Cengage Learning, 2012.

↩ -

Fischer, Robert, et al. The Automotive Transmission Book Powertrain. Springer, 2015.

↩ -

Jazar, Reza N. Vehicle Dynamics: Theory and Application. Springer, 2017.

↩

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.