This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

Introduction

The Cummins 5302716 Inlet Catalyst Module is a component designed for use in commercial trucks. It is part of the exhaust aftertreatment system, which is responsible for reducing harmful emissions produced by diesel engines. This module plays a significant role in the operation of commercial trucks by ensuring that the exhaust gases meet environmental standards before being released into the atmosphere.

Function and Operation

The Inlet Catalyst Module is positioned within the exhaust system, typically upstream of other aftertreatment components such as the Diesel Particulate Filter (DPF) and Selective Catalytic Reduction (SCR) system. Its primary function is to facilitate the oxidation of hydrocarbons (HC) and carbon monoxide (CO) into less harmful substances such as carbon dioxide (CO2) and water (H2O). This process occurs as the exhaust gases pass through the catalyst, which is coated with precious metals that promote the chemical reactions necessary for emission reduction 1.

Purpose of the Inlet Catalyst Module

The Inlet Catalyst Module contributes to reducing emissions by converting harmful pollutants into less harmful substances. This not only improves engine efficiency but also helps in meeting stringent environmental regulations. By reducing the levels of HC and CO in the exhaust, the module ensures that the truck’s emissions are within the limits set by environmental agencies, thus promoting cleaner air quality 2.

Key Features

The Cummins 5302716 Inlet Catalyst Module is characterized by several key features. Its design incorporates a robust housing that protects the catalyst material from physical damage. The module utilizes high-quality materials to ensure durability and longevity. Technological advancements in the catalyst coating enhance its efficiency in reducing emissions, making it a reliable component in the aftertreatment system.

Benefits

Using the Inlet Catalyst Module offers several advantages. It contributes to improved fuel efficiency by optimizing the exhaust aftertreatment process. Additionally, it reduces emissions, which is beneficial for both the environment and the truck operator, as it helps in complying with emission regulations. The module also supports the overall performance of the truck by ensuring that the engine operates within the parameters set for emission control.

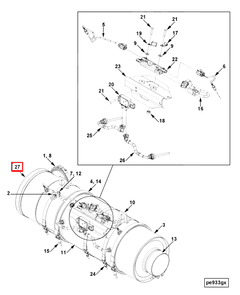

Installation Process

Installing the Inlet Catalyst Module requires careful attention to detail. The process involves disconnecting the exhaust system at the appropriate points, removing the old module if present, and then fitting the new module into place. It is important to use the correct tools and follow the manufacturer’s guidelines to ensure a proper fit and seal. Once installed, the exhaust system should be reassembled, and the connections should be checked for leaks.

Maintenance and Troubleshooting

Regular maintenance of the Inlet Catalyst Module is important to ensure its continued effectiveness. This includes inspecting the module for any signs of damage or wear and ensuring that the exhaust system is free from obstructions. Common issues that may arise include catalyst poisoning due to contamination or physical damage to the module. Troubleshooting steps may involve cleaning the catalyst or replacing the module if necessary.

Performance Impact

The Inlet Catalyst Module has a noticeable impact on the overall performance of the truck. By reducing emissions, it helps in maintaining engine efficiency and ensuring that the truck operates within the required emission standards. This can lead to improved fuel consumption and reduced maintenance costs over time, as a well-maintained aftertreatment system contributes to the longevity of the engine and other components.

Regulatory Compliance

The Inlet Catalyst Module plays a role in helping trucks comply with various emission regulations and standards. By reducing the levels of harmful emissions, it ensures that the truck meets the requirements set by environmental agencies. This is particularly important in regions with strict emission control laws, where non-compliance can result in fines or restrictions on vehicle operation 3.

Cummins Overview

Cummins Inc. is a global power leader that designs, manufactures, and distributes engines, filtration, and power generation products. With a history spanning over a century, Cummins has established itself as a key player in the commercial truck industry, providing innovative solutions that enhance the performance, efficiency, and reliability of diesel engines. The company’s commitment to sustainability and environmental stewardship is reflected in its development of advanced emission control technologies, including the Inlet Catalyst Module.

Conclusion

The Cummins 5302716 Inlet Catalyst Module is a vital component in the exhaust aftertreatment system of commercial trucks. It plays a crucial role in reducing harmful emissions, ensuring compliance with environmental regulations, and enhancing the overall performance and efficiency of the truck. Regular maintenance and proper installation are essential to maximize the benefits of this Cummins part.

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.