5302727

Inlet Catalyst Module

Cummins®

AVAILABLE

3 are currently available

Ships within 2-4 business days

This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

Introduction

The Cummins 5302727 Inlet Catalyst Module is a component designed for the emissions control system of heavy-duty trucks. Its purpose is to reduce harmful emissions, particularly nitrogen oxides (NOx), before they are released into the atmosphere. This module is integral to the overall emissions reduction strategy employed in modern diesel engines, working in conjunction with other systems to ensure compliance with environmental regulations.

Purpose and Function

The Inlet Catalyst Module plays a role in reducing emissions by targeting nitrogen oxides (NOx) within the exhaust stream. It is a part of the Selective Catalytic Reduction (SCR) system, which uses a chemical reaction to convert NOx into nitrogen and water vapor 1. The module is positioned upstream in the exhaust system, where it pre-treats the exhaust gases before they reach the main SCR catalyst. This pre-treatment enhances the overall efficiency of the SCR system by ensuring that the exhaust gases are in an optimal state for the reduction reaction.

Key Features

This Cummins part is characterized by several key features that enhance its performance and durability. Its design incorporates advanced catalyst materials that are resistant to thermal degradation and poisoning by contaminants. The module is constructed using high-quality materials to withstand the harsh conditions of the exhaust system. Technological advancements such as improved catalyst coating techniques and optimized substrate designs contribute to its effectiveness in reducing emissions 2.

Benefits

The advantages of the Inlet Catalyst Module include improved emission reduction efficiency, ensuring that heavy-duty trucks meet stringent environmental regulations. By optimizing the exhaust treatment process, the module also contributes to better engine performance, which can lead to potential fuel savings. Additionally, its integration into the SCR system helps in maintaining the overall efficiency of the emissions control system 3.

Installation and Integration

Proper installation of the Inlet Catalyst Module within the truck’s exhaust system is vital for its optimal performance. Installation guidelines recommend ensuring that the module is securely mounted and that all connections are properly sealed to prevent leaks. Depending on the truck’s configuration, some modifications to the exhaust system may be necessary to accommodate the module. Following manufacturer recommendations for installation ensures that the module functions as intended.

Maintenance and Care

Regular maintenance practices are essential to ensure the longevity and effectiveness of the Inlet Catalyst Module. Inspection intervals should be observed to check for signs of wear, damage, or contamination. Cleaning procedures may be required to remove any buildup that could impede the module’s performance. Monitoring the module’s condition and addressing any issues promptly helps in maintaining its efficiency and durability.

Troubleshooting Common Issues

Common problems associated with the Inlet Catalyst Module may include reduced efficiency or physical damage. Diagnostic steps to identify these issues involve checking for proper installation, inspecting for signs of damage, and ensuring that the module is functioning within its operational parameters. Solutions may range from cleaning the module to replacing damaged components, depending on the nature of the problem.

Environmental Impact

The Inlet Catalyst Module contributes to reducing the environmental footprint of heavy-duty trucks by playing a role in meeting stringent emission standards. Its function in the SCR system helps in promoting cleaner air by significantly lowering the levels of nitrogen oxides released into the atmosphere. This reduction in emissions is a step towards more sustainable transportation solutions.

Technological Innovations

The design of the 5302727 incorporates several technological innovations that improve its performance and durability. Advanced catalyst materials and enhanced structural designs are among the innovations that contribute to its effectiveness. These technological advancements ensure that the module can withstand the demanding conditions of the exhaust system while maintaining high levels of emission reduction efficiency.

Cummins Overview

Cummins Inc. is a leader in diesel engine technology, with a history of innovation and expertise in developing solutions for emissions control. The company’s commitment to advancing commercial trucking technology is evident in its development of the Inlet Catalyst Module. Cummins continues to push the boundaries of what is possible in emissions reduction, contributing to a cleaner and more sustainable future for the industry.

Engine Compatibility

The 5302727 is specifically designed to integrate with the following Cummins engine models:

- QSB6.7 CM2250

This part ensures optimal performance and compliance with environmental regulations across these engine types. Its design allows for a precise fit, ensuring that it functions effectively within the engine’s exhaust system.

Installation and Functionality

When installed, the 5302727 works in conjunction with the engine’s exhaust system to convert harmful pollutants into less harmful emissions. This is achieved through a catalytic process that occurs within the module, which is strategically placed to maximize efficiency.

The module’s design ensures that it can withstand the high temperatures and pressures typical of engine operations. This durability is crucial for maintaining the integrity of the catalytic process over time, thereby ensuring consistent performance and reliability.

Importance in Engine Performance

The proper functioning of the 5302727 is essential for the overall performance of the engine. By reducing emissions, it helps the engine to operate more efficiently and in compliance with environmental standards. This is particularly important in applications where emission regulations are stringent.

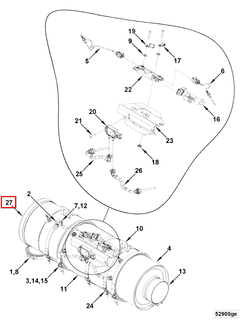

Role in Aftertreatment Device

The 5302727 is an integral component within the aftertreatment device of an engine system. Its primary function is to facilitate the initial stages of exhaust gas treatment before the gases enter the main aftertreatment components.

When exhaust gases exit the engine, they pass through the Inlet Catalyst Module, where preliminary catalytic reactions begin. This module is designed to reduce the temperature of the exhaust gases slightly and to start breaking down certain pollutants.

The treated gases then move on to subsequent components within the aftertreatment device, such as the Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), and Selective Catalytic Reduction (SCR) system. Each of these components relies on the conditioned exhaust gases from the Inlet Catalyst Module to operate more efficiently.

In essence, the 5302727 sets the stage for the aftertreatment process, ensuring that the subsequent components receive exhaust gases that are more amenable to further purification. This sequential treatment is essential for meeting emissions standards and ensuring the overall effectiveness of the aftertreatment system.

Conclusion

The Cummins 5302727 Inlet Catalyst Module is a vital component in the emissions control system of heavy-duty trucks. Its role in reducing nitrogen oxides and other harmful emissions contributes to better engine performance and compliance with environmental regulations. Through its integration into the SCR system and other aftertreatment components, this part ensures that heavy-duty trucks operate more efficiently and with a reduced environmental impact.

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.