This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

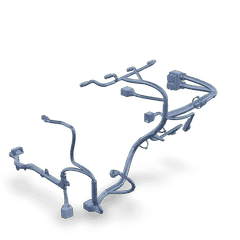

The 5309057 Electrical Wiring Assembly by Cummins is a specialized component designed for use in commercial trucks. This assembly plays a significant role in the electrical system of these vehicles, ensuring that various electrical components function correctly and efficiently. Its purpose is to provide a reliable and efficient means of transmitting electrical power and signals throughout the truck, contributing to overall vehicle performance and safety 1.

Basic Concepts of Electrical Wiring Assembly

Electrical wiring assemblies are integral to the operation of a truck’s electrical system. They consist of a network of wires, connectors, and terminals that facilitate the transmission of electrical power and signals between different components. These assemblies are designed to handle various voltages and currents, ensuring that all electrical systems within the truck operate as intended 2. Understanding the fundamental principles of these assemblies, including their components and functions, is crucial for maintaining and troubleshooting the electrical systems in commercial trucks.

Purpose of the 5309057 Electrical Wiring Assembly

The 5309057 Electrical Wiring Assembly is designed to integrate seamlessly with other electrical components and systems within a truck. It plays a role in distributing electrical power to critical systems such as the engine, lighting, and various sensors. By providing a structured and organized method for electrical distribution, this assembly helps ensure that all electrical components receive the necessary power and signals to function correctly. Its integration with other systems enhances the overall efficiency and reliability of the truck’s electrical network 3.

Key Features

The 5309057 Electrical Wiring Assembly boasts several key features that enhance its performance and reliability. Its design incorporates high-quality materials that are resistant to wear and environmental factors, ensuring durability in demanding conditions. The assembly is engineered with precision to fit specific truck models, reducing the risk of installation errors. Additionally, it includes unique characteristics such as corrosion-resistant coatings and robust connectors, which contribute to its longevity and efficiency 4.

Benefits

The benefits of using the 5309057 Electrical Wiring Assembly include improved electrical efficiency and reliability. By providing a structured and organized method for electrical distribution, this assembly helps reduce the risk of electrical faults and failures. It also contributes to enhanced truck performance and safety by ensuring that all electrical systems operate as intended. The assembly’s design and materials also help minimize maintenance requirements, providing long-term value to fleet operators 5.

Installation Process

Proper installation of the 5309057 Electrical Wiring Assembly is crucial for ensuring its correct fit and function. The process involves several steps, including preparing the truck’s electrical system, routing the wires according to the manufacturer’s specifications, and securing all connections. Tools and equipment required for installation may include wire strippers, crimping tools, and multimeters for testing connections. It is important to follow the manufacturer’s guidelines to ensure a successful installation and to avoid potential issues 6.

Troubleshooting Common Issues

Common problems that may arise with the 5309057 Electrical Wiring Assembly include loose connections, damaged wires, and faulty connectors. Troubleshooting these issues involves identifying the source of the problem, which may require testing individual components with a multimeter. Solutions can range from tightening connections to replacing damaged parts. Regular inspections and maintenance can help prevent many of these issues, ensuring the assembly continues to function correctly 7.

Maintenance Tips

To ensure the longevity and optimal performance of the 5309057 Electrical Wiring Assembly, regular maintenance is recommended. This includes inspecting the assembly for signs of wear or damage, ensuring all connections are secure, and cleaning any corrosion from terminals. Following a recommended maintenance schedule can help identify potential issues before they become serious problems, contributing to the overall reliability of the truck’s electrical system 8.

Safety Considerations

When working with the 5309057 Electrical Wiring Assembly, it is important to observe safety protocols and precautions to prevent accidents and ensure personal safety. This includes disconnecting the battery before beginning any work on the electrical system, using insulated tools to avoid electrical shocks, and wearing appropriate personal protective equipment. Adhering to these safety measures helps protect both the technician and the vehicle 9.

Cummins: A Brief Overview

Cummins Inc. is a leading manufacturer in the commercial truck industry, known for its commitment to quality and innovation. The company offers a wide range of products, including engines, powertrains, and electrical systems, designed to meet the demanding requirements of commercial vehicles. Cummins’ reputation for reliability and performance is built on a history of technological advancement and a dedication to customer satisfaction. The 5309057 Electrical Wiring Assembly is a testament to Cummins’ expertise in providing high-quality components that enhance the efficiency and safety of commercial trucks 10.

Cummins Electrical Wiring Assembly Part 5309057

The Cummins Electrical Wiring Assembly part number 5309057 is specifically designed to integrate seamlessly with a range of Cummins engines, ensuring reliable and efficient electrical connectivity. This part is engineered to fit within the engine architecture of the QSB3.3 CM2150 series, providing a critical link in the engine’s electrical system.

In the QSB3.3 CM2150 engines, the Electrical Wiring Assembly part 5309057 is meticulously crafted to interface with the engine’s electrical components. It ensures that all necessary electrical signals are transmitted accurately and efficiently, which is crucial for the engine’s performance and longevity. This wiring assembly is designed to withstand the operational stresses of the engine, maintaining its integrity and functionality over time.

The integration of part 5309057 into the QSB3.3 CM2150 engines is a testament to Cummins’ commitment to quality and reliability. By ensuring that this wiring assembly fits perfectly within the engine’s design, Cummins guarantees that the engine’s electrical system operates smoothly, reducing the risk of malfunctions and enhancing overall performance 11.

Role of Part 5309057 Electrical Wiring Assembly in Engine Systems

The 5309057 Electrical Wiring Assembly is integral to the seamless operation of engine systems, particularly in its interaction with the harness and the Electronic Control Module (ECM) wiring.

Interaction with Harness

The harness serves as the primary conduit for electrical signals and power throughout the engine system. The 5309057 Electrical Wiring Assembly interfaces directly with the harness, ensuring that all necessary connections are secure and efficient. This assembly facilitates the transmission of data and power to various engine components, such as sensors, actuators, and the ECM. Its design allows for flexibility and durability, accommodating the dynamic environment within the engine compartment 12.

Integration with ECM Wiring

The ECM is the brain of the engine system, responsible for processing data from various sensors and controlling actuators to optimize engine performance. The 5309057 Electrical Wiring Assembly plays a significant role in this process by providing the necessary connections between the ECM and other engine components. It ensures that the ECM receives accurate and timely data, enabling it to make precise adjustments to fuel injection, ignition timing, and other critical parameters. Additionally, the assembly allows the ECM to send control signals to actuators, ensuring that the engine operates within optimal parameters 13.

Enhanced System Reliability

By ensuring robust and reliable connections, the 5309057 Electrical Wiring Assembly contributes to the overall reliability of the engine system. It minimizes the risk of electrical faults, which can lead to engine misfires, reduced performance, or even complete system failure. The assembly’s design also incorporates protective measures against environmental factors such as moisture, heat, and vibration, further enhancing its durability and performance 14.

Facilitating Diagnostics and Maintenance

The 5309057 Electrical Wiring Assembly is designed with maintenance and diagnostics in mind. Its structured layout and clear labeling simplify the process of identifying and troubleshooting electrical issues. This feature is particularly beneficial during routine maintenance checks or when diagnosing complex engine problems, allowing mechanics to quickly locate and address any wiring-related issues 15.

Conclusion

In summary, the 5309057 Electrical Wiring Assembly is a vital component that ensures the efficient and reliable operation of engine systems by seamlessly integrating with the harness and ECM wiring. Its role in data transmission, system reliability, and ease of maintenance underscores its importance in modern engine technology.

-

Boyce, M. P. (2002). Gas Turbine Engineering Handbook, Second Edition. Gulf Professional Publishing.

↩ -

Zhao, H. (2010). Advanced Direct Injection Combustion Engine Technologies and Development Volume 2 Diesel Engines. CRC Press.

↩ -

Rendle, S., & Randall, M. (2000). Haynes Diesel Engine Systems and Data Book. Haynes Publishing.

↩ -

Cummins Inc. (n.d.). Fault Code Troubleshooting Manual. Bulletin Number 5613122.

↩ -

Boyce, M. P. (2002). Gas Turbine Engineering Handbook, Second Edition. Gulf Professional Publishing.

↩ -

Cummins Inc. (n.d.). Fault Code Troubleshooting Manual. Bulletin Number 5613122.

↩ -

Zhao, H. (2010). Advanced Direct Injection Combustion Engine Technologies and Development Volume 2 Diesel Engines. CRC Press.

↩ -

Rendle, S., & Randall, M. (2000). Haynes Diesel Engine Systems and Data Book. Haynes Publishing.

↩ -

Cummins Inc. (n.d.). Fault Code Troubleshooting Manual. Bulletin Number 5613122.

↩ -

Boyce, M. P. (2002). Gas Turbine Engineering Handbook, Second Edition. Gulf Professional Publishing.

↩ -

Cummins Inc. (n.d.). Fault Code Troubleshooting Manual. Bulletin Number 5613122.

↩ -

Zhao, H. (2010). Advanced Direct Injection Combustion Engine Technologies and Development Volume 2 Diesel Engines. CRC Press.

↩ -

Rendle, S., & Randall, M. (2000). Haynes Diesel Engine Systems and Data Book. Haynes Publishing.

↩ -

Cummins Inc. (n.d.). Fault Code Troubleshooting Manual. Bulletin Number 5613122.

↩ -

Boyce, M. P. (2002). Gas Turbine Engineering Handbook, Second Edition. Gulf Professional Publishing.

↩

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.