This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

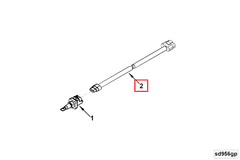

The 5309569 Wiring Harness Assembly, a component designed by Cummins, plays a significant role in the electrical system of commercial trucks. This assembly facilitates the connection between various electrical components and systems, ensuring efficient and safe truck operations 1.

Basic Concepts of Wiring Harness Assembly

A wiring harness assembly is a collection of wires, terminals, and connectors that run throughout a vehicle’s electrical system. It serves as the central nervous system for the truck, allowing for the transmission of electrical signals between different components. Proper wiring is vital for ensuring the efficient and safe operation of a truck, minimizing the risk of electrical faults and enhancing overall performance 2.

Purpose of the 5309569 Wiring Harness Assembly

This Cummins part is designed to facilitate the connection between various electrical components within a truck. It ensures that signals and power are correctly routed to and from different parts of the vehicle, supporting the functionality of critical systems such as lighting, engine management, and safety features 3.

Key Features

The 5309569 Wiring Harness Assembly boasts several key features that enhance its performance and durability. These include a robust design that withstands the harsh conditions of commercial truck environments, high-quality materials that resist wear and corrosion, and unique attributes such as integrated circuit protection and modular design elements that simplify installation and maintenance 4.

Benefits

Utilizing this part offers several advantages. It contributes to improved electrical efficiency within the truck, reducing the likelihood of short circuits and other electrical faults. Additionally, the assembly incorporates enhanced safety features that protect against electrical hazards, ensuring a safer operating environment for the vehicle.

Installation Process

Installing the 5309569 Wiring Harness Assembly involves a series of steps to ensure proper integration with the truck’s electrical system. The process requires specific tools and equipment, and it is important to observe safety precautions throughout. Detailed instructions should be followed to ensure the assembly is correctly installed, securing all connections and verifying the system’s functionality post-installation.

Troubleshooting and Maintenance

Common issues with the 5309569 Wiring Harness Assembly may include loose connections, damaged wires, or faulty terminals. Troubleshooting these issues involves inspecting the assembly for signs of wear or damage, testing electrical connections, and replacing any compromised components. Regular maintenance, such as cleaning and inspecting the harness for potential issues, can help ensure its longevity and optimal performance.

Cummins: Manufacturer Overview

Cummins Inc. is a well-established name in the commercial truck industry, known for its wide range of high-quality automotive components. With a history of innovation and a commitment to quality, Cummins has built a reputation for producing reliable and efficient parts. The company’s product range includes engines, filtration systems, and electrical components, all designed to meet the demanding requirements of commercial trucking.

Compatibility with Cummins Engines

-

QSB6.7 M CM2250: This engine model benefits from the precise wiring harness assembly, ensuring that all electrical components are properly connected and functioning. The harness is designed to withstand the operational stresses of the engine, providing a stable and durable connection.

-

QSB6.7 M CM2250 Group: This group of engines shares similar electrical architecture, making the 5309569 wiring harness assembly a versatile choice. The harness is tailored to meet the specific electrical needs of these engines, ensuring optimal performance and reliability.

Role of 5309569 Wiring Harness Assembly in Engine Systems

The 5309569 Wiring Harness Assembly is an integral component in the electrical system of engine setups, facilitating the connection between various sensors and the engine control unit (ECU). This assembly ensures that the electrical signals from sensors are accurately transmitted to the ECU for processing.

Integration with Sensors

In engine systems, sensors play a pivotal role in monitoring various parameters such as temperature, pressure, and fluid levels. The Wiring Harness Assembly interfaces directly with these sensors, providing a structured pathway for the electrical signals. For instance, temperature sensors located within the engine block or exhaust system rely on this harness to send real-time data to the ECU. This data is essential for the ECU to make adjustments to fuel injection, ignition timing, and other critical functions to optimize engine performance and efficiency.

Coolant Level Monitoring

Another significant application of the Wiring Harness Assembly is in the coolant system. Coolant level sensors are vital for preventing engine overheating, which can lead to severe damage. The harness connects these sensors to the ECU, allowing for continuous monitoring of the coolant level. If the coolant level drops below a safe threshold, the ECU can trigger warnings or take corrective actions, such as adjusting the engine’s operating parameters to reduce the risk of overheating.

Enhanced System Reliability

By providing a reliable and organized connection between sensors and the ECU, the Wiring Harness Assembly enhances the overall reliability of the engine system. It reduces the likelihood of electrical faults that could otherwise lead to inaccurate sensor readings, ensuring that the ECU receives precise data for making informed decisions.

Conclusion

The 5309569 Wiring Harness Assembly is a foundational element in the electrical architecture of engine systems, enabling efficient communication between sensors and the ECU, and thereby contributing to the engine’s performance, safety, and longevity.

-

Singh, D. K. (2024). Dictionary of Mechanical Engineering. Springer Nature.

↩ -

Minaker, B. P. (2019). Fundamentals of Vehicle Dynamics and Modelling. John Wiley & Sons.

↩ -

Duffy, O. C., & Wright, G. (2016). Fundamentals of Medium-Heavy Duty Commercial Vehicle Systems. Jones & Bartlett Learning.

↩ -

Bennett, S. (2012). Modern Diesel Technology: Light Duty Diesels. Cengage Learning.

↩

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.